Double-faced relief noble metal foil and forming process thereof

A forming process and precious metal technology, applied in the field of double-sided embossed precious metal foil and its forming process, can solve the problems of the three-dimensional embossed pattern of mimeograph pattern film being comparable, losing the advantage of gold color and lustre, affecting customer experience, etc., to achieve the best customer experience, The effect of stable product yield and reliable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

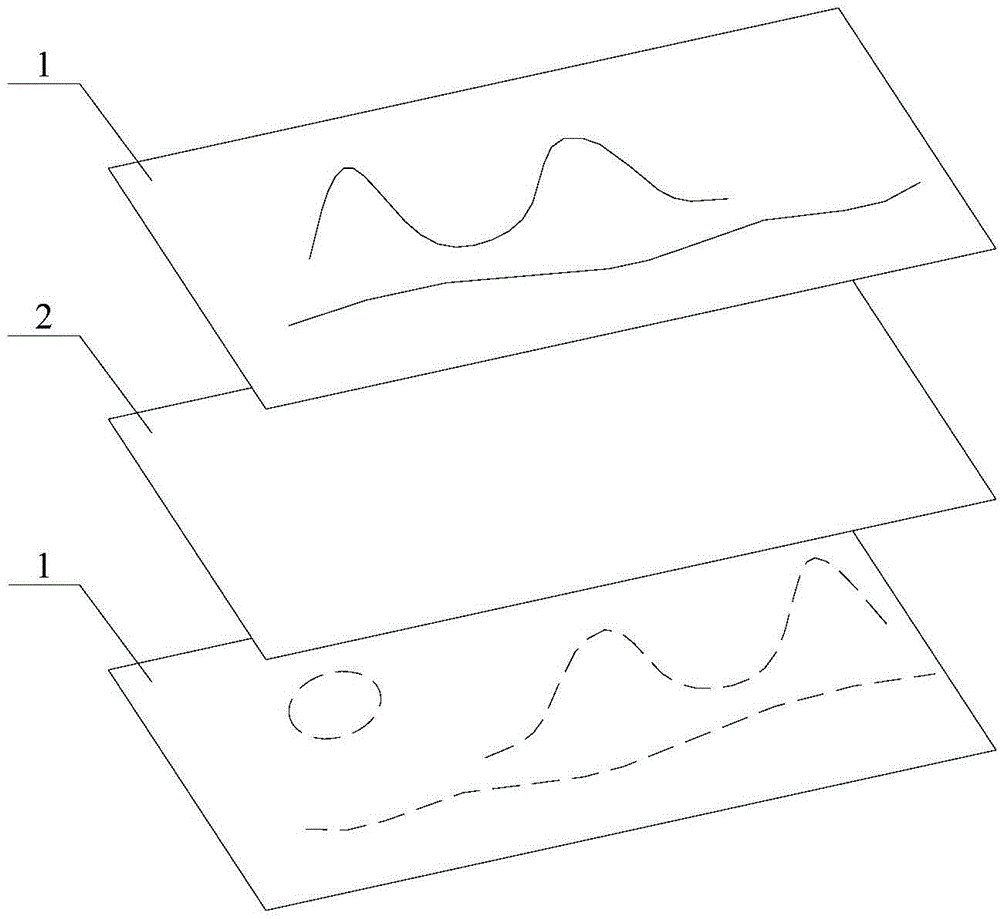

[0044] Based on the existing forming process of the embossed pattern on the surface of the noble metal foil, the present invention finds a new way to improve the design, so as to meet the trend requirement of achieving the largest area under the smallest grammage of the foil to the greatest extent. The present embodiment will be described in detail below in conjunction with the accompanying drawings.

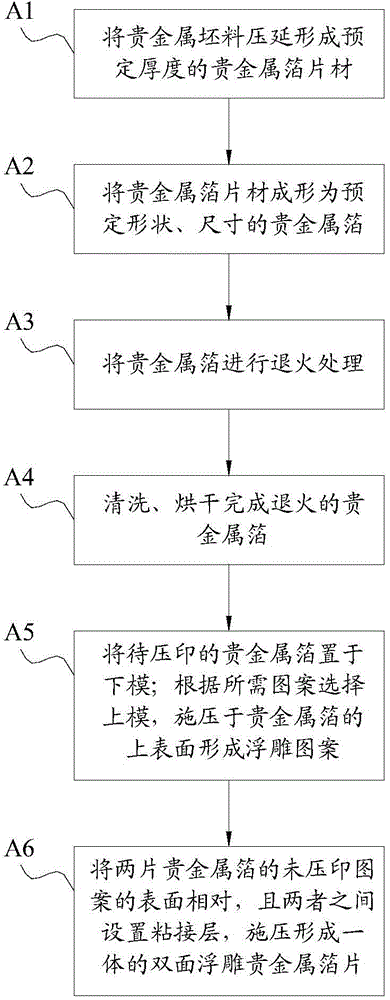

[0045] See figure 1 , which shows a flow chart of the forming process of the double-sided embossed precious metal foil according to this embodiment.

[0046] The forming process of the double-sided embossed precious metal foil comprises the following steps:

[0047] A1. Rolling the precious metal blank to form a precious metal foil sheet with a predetermined thickness;

[0048] A2. forming the precious metal foil sheet obtained in step A1 into a precious metal foil of predetermined shape and size;

[0049] A3. annealing the precious metal foil obtained in step A2;

[0050] A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com