An all-season driving wheel tire pattern

A tire pattern and driving wheel technology, applied in the field of tire tread patterns, can solve the problems of tire cord force changes, tire pressure changes, damage, etc., to achieve the effects of preventing abnormal wear, good heat dissipation, and low rolling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

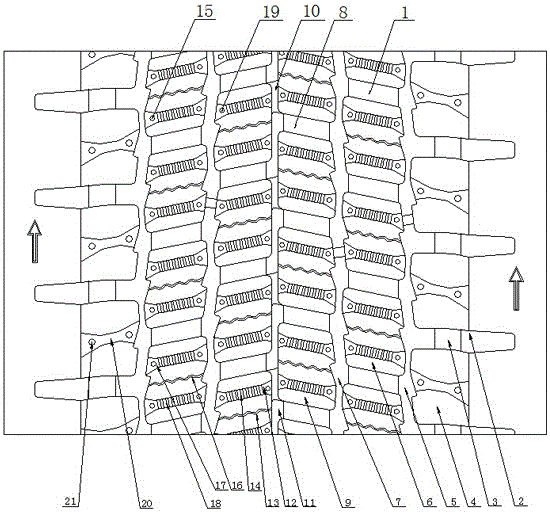

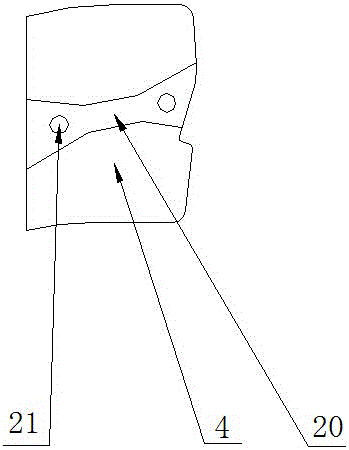

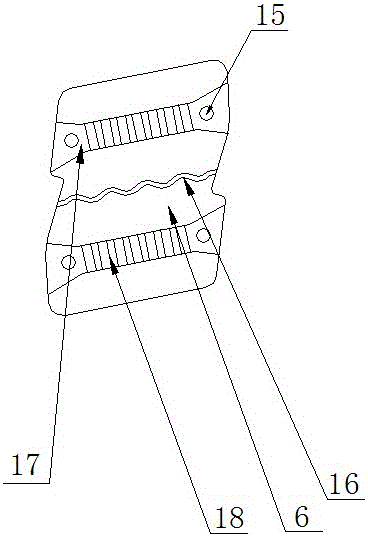

[0025] as attached Figure 1-6 As shown, an all-season drive wheel tire pattern includes first pattern blocks 4 arranged circumferentially on the tire shoulders, adjacent first pattern blocks 4 are connected by first ribs 3, and the first ribs 3 The corresponding shoulder part is provided with a fourth groove 2, with the center line of the tread as the line of symmetry, the inner side of the first pattern block 4 is provided with a second pattern block 6 along the circumferential direction, the first pattern block 4 and the second pattern block A first pattern groove 5 is arranged between the pattern blocks 6, a third pattern block 9 along the circumferential direction is arranged on the inner side of the second pattern block 6, and a second pattern pattern is arranged between the second pattern block 6 and the third pattern block 9. Grooves 7 and third grooves 11 are arranged between adjacent third blocks 9 .

[0026] The width of the first reinforcing rib 3 is smaller than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com