Rotary table

The technology of a turntable and transmission system is applied to the turntable. It can solve the problems that affect the life of the motor and cannot realize intermittent stop, so as to achieve the effect of not affecting the life of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

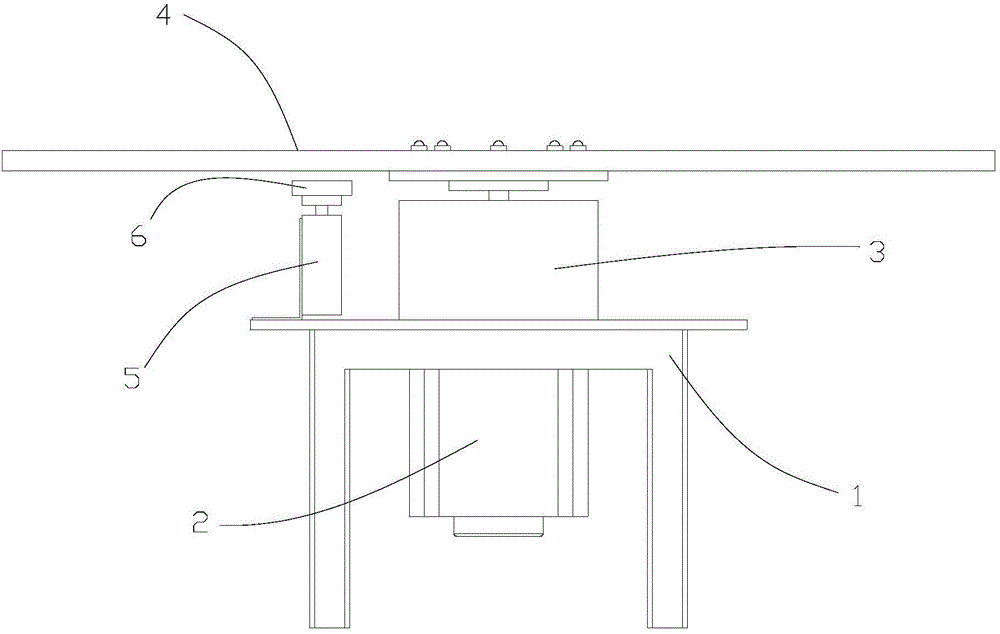

[0029] see figure 1 and figure 2 , the invention discloses a turntable main body 4, comprising a frame 1, a motor 2, a transmission system 3, a turntable main body 4 and a stop device; the transmission system 3 and the motor 2 are installed on the frame 1, and the motor 2 and the transmission system 3 Drive connection; the turntable main body 4 is connected to the transmission system 3; the stop device is installed on the frame 1, and the stop device is offset against the turntable main body 4 when it moves;

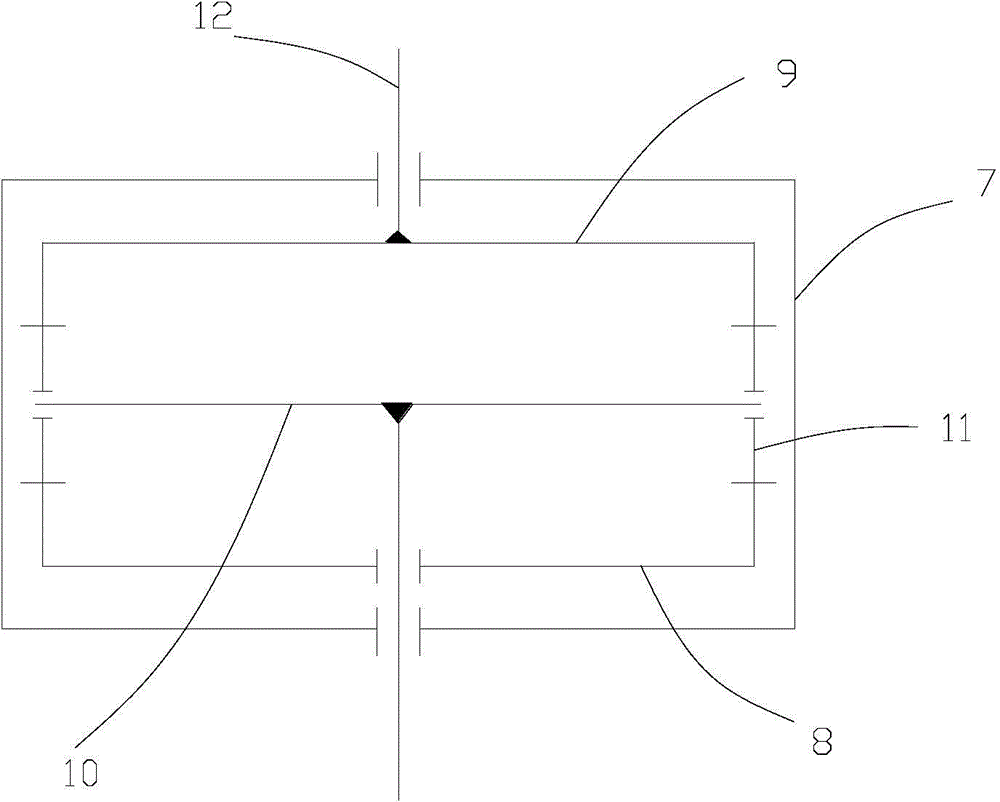

[0030] Transmission system 3 comprises housing 7, input shaft 10, rotating gear 11, first gear 8 and second gear 9; The input end of 10 is exposed outside the shell 7 and is connected to the motor 2; two rotating gears 11 are respectively connected to the two gear mounting ends of the input shaft 10; the center of the first gear 8 is provided with a central hole, and the second gear The center of 9 is provided with outward axially protruding output shaft 12, the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com