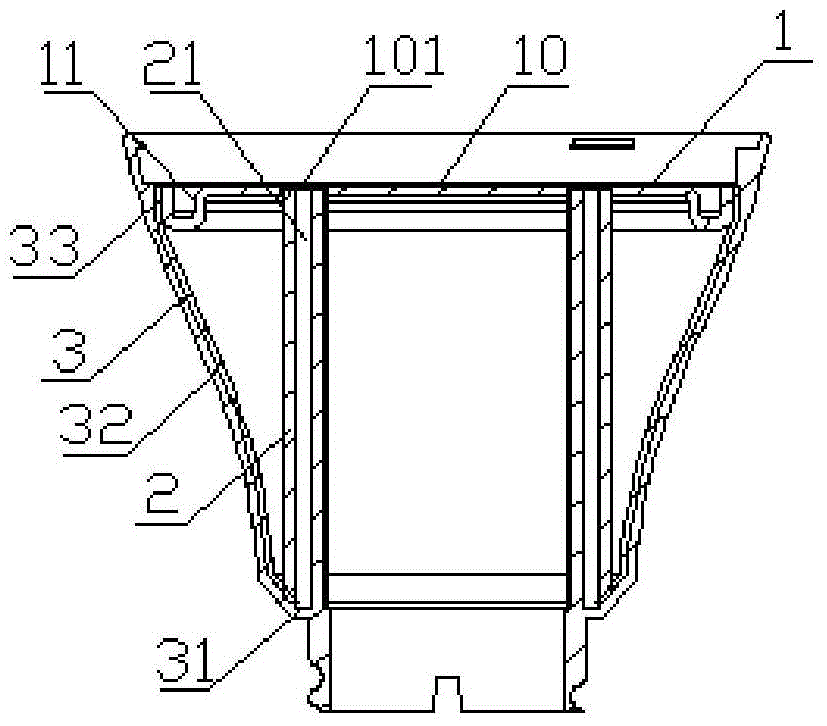

LED lamp radiating assembly

A technology for heat dissipation components and LED lamps, which is applied in lighting and heating equipment, cooling/heating devices for lighting devices, lighting devices, etc., can solve the problems of reducing the contact area between the aluminum substrate and the cover plate, increasing the cost, and being unable to dissipate heat. To achieve the effect of not easy to slip teeth, increase the effective number of teeth, and maintain the flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

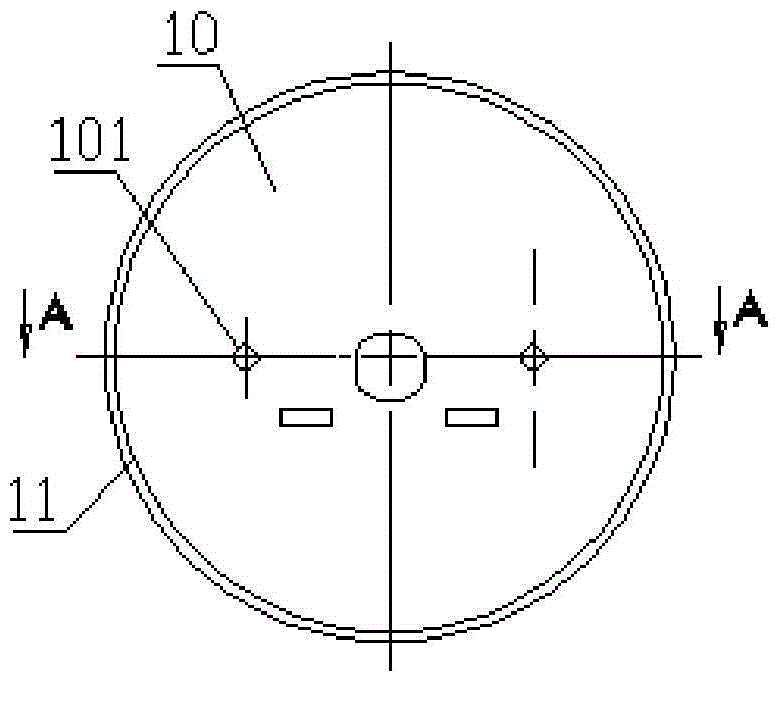

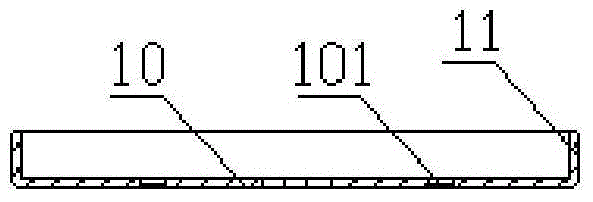

[0022] In embodiment 2, such as Figure 4 As shown, the screw hole is provided with an inversion 102, and the inversion protrudes upwards from the cover plate. When screwing the aluminum base plate before the improvement, there is no positioning hole, and manual alignment is required, which is time-consuming and laborious, and may cause misalignment of the holes and misalignment of the screws. It is based on the round hole type screw hole before improvement, and the hole is stretched back, forming a raised shape on the back of the radiator cover, which is convenient for increasing the number of effective threads of the thread when the aluminum substrate is subsequently assembled. Strengthen the fixing effect on the screw, and also play the role of not easy to slip teeth.

[0023] In addition, in this embodiment, the flange 11 is provided with a reinforcing structure, and the reinforcing structure is an indented structure 111 in which the chamfered part is recessed toward the ...

Embodiment 3

[0024] In embodiment 3, such as Figure 5 As shown, the inversion protrudes to the bottom of the cover plate. It stretches the hole on the basis of the round hole screw hole before improvement, so that the aluminum substrate can be directly fixed when the aluminum substrate is screwed, reducing unnecessary time for employees to align the hole, saving time and effort.

Embodiment 4

[0025] Example 4, such as Image 6 As shown, the flange is a U-shaped bending structure, which can increase the heat dissipation area of the cover plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com