Turbine refrigerator

A technology of turbo refrigerator and turbo compressor, which is applied in the field of expansion mechanism, can solve the problems of inability to perform high-precision liquid level control, poor controllability of electric expansion valve, and increased cost, so as to achieve a good operating area and solve control response Reduction of performance and the effect of securing control responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below, refer to Figure 1 ~ Figure 5 An embodiment of the turbo refrigerator according to the present invention will be described. in Figure 1 ~ Figure 5 Here, the same or equivalent components are denoted by the same reference numerals, and repeated descriptions are omitted.

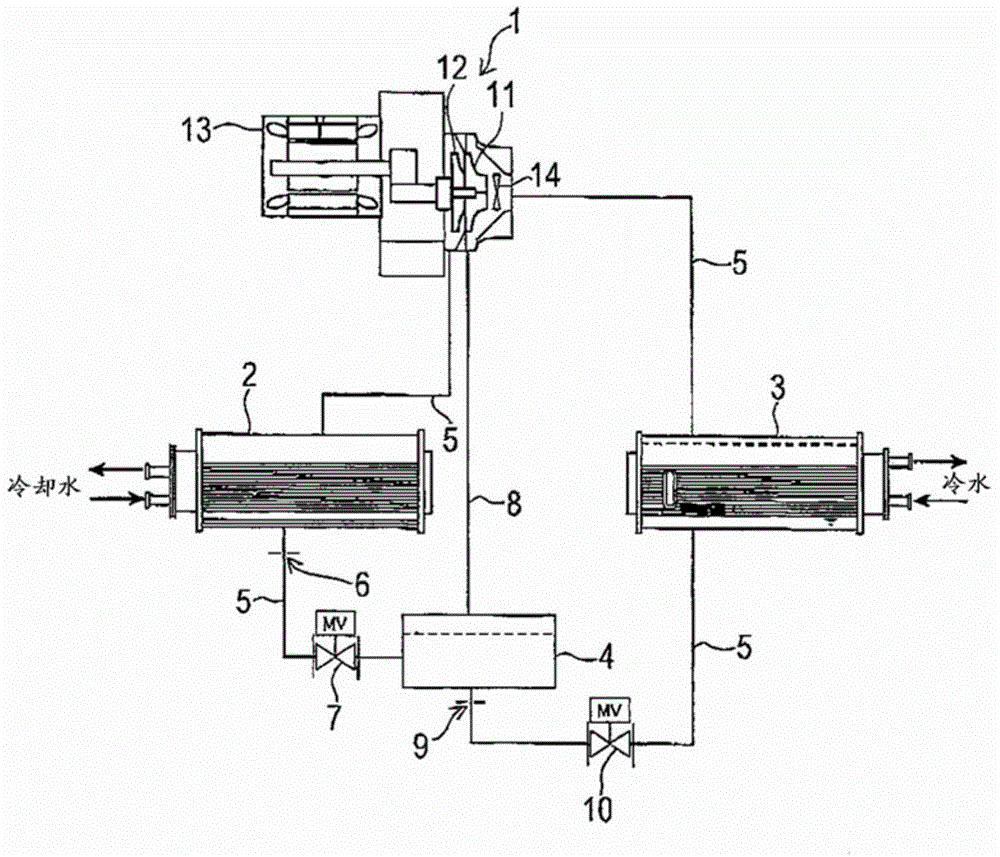

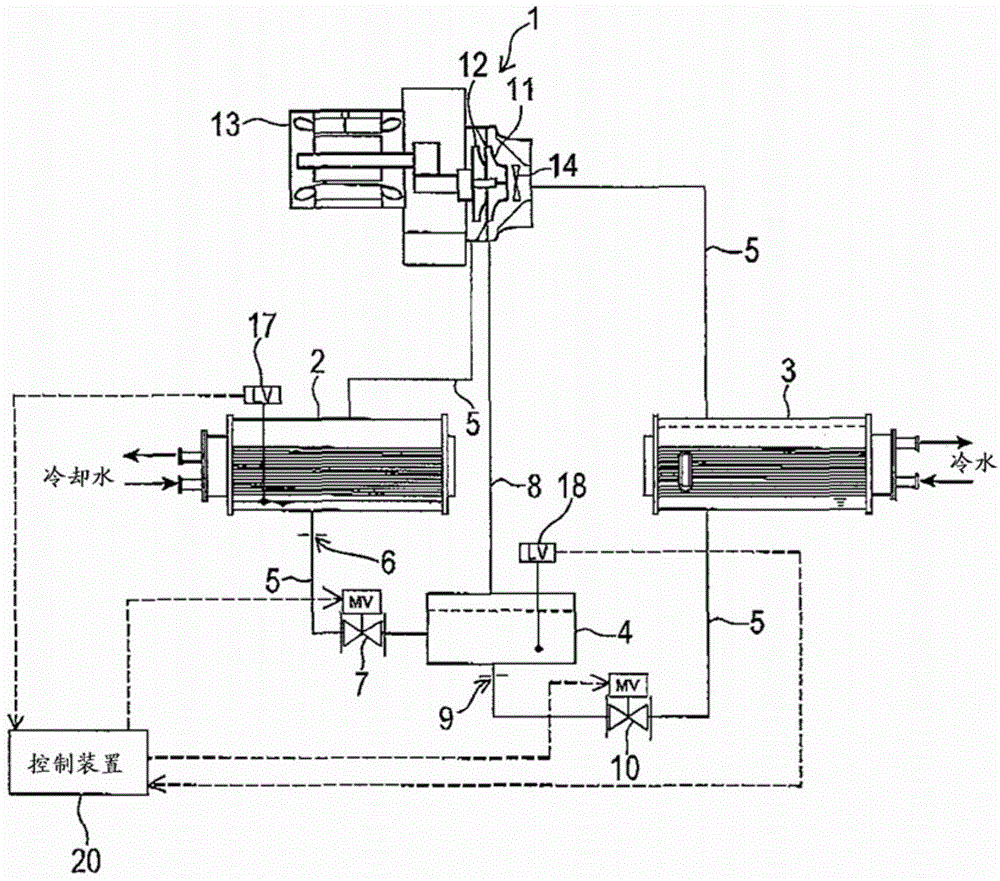

[0035] figure 1 It is a schematic diagram showing the first embodiment of the turbo refrigerator according to the present invention. Such as figure 1 As shown, the turbo refrigerator is equipped with: a turbo compressor 1, which compresses the refrigerant; a condenser 2, which uses cooling water (cooling fluid) to cool and condense the compressed refrigerant gas; and an evaporator 3, It obtains heat from the cold water (cooled fluid) to evaporate the refrigerant to exert its cooling effect; and the economizer 4 as an intercooler is arranged between the condenser 2 and the evaporator 3, and the turbo refrigeration mechanism uses the refrigerant The circulating refrigerant pipe 5 connects the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com