Compensation method for multi-tooth uneven cutting behavior of high-speed milling cutter

A compensation method and high-speed milling technology, which is applied in the compensation of cutting behavior of high-speed milling cutters and in the field of compensation of uneven cutting behavior of high-speed milling cutters with multiple teeth, can solve problems such as uneven cutting and reduced quality of processed surfaces, and reduce machining Surface roughness, improving the uneven cutting state of the cutter teeth, and reducing the effect of the unevenness of the machined surface topography

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

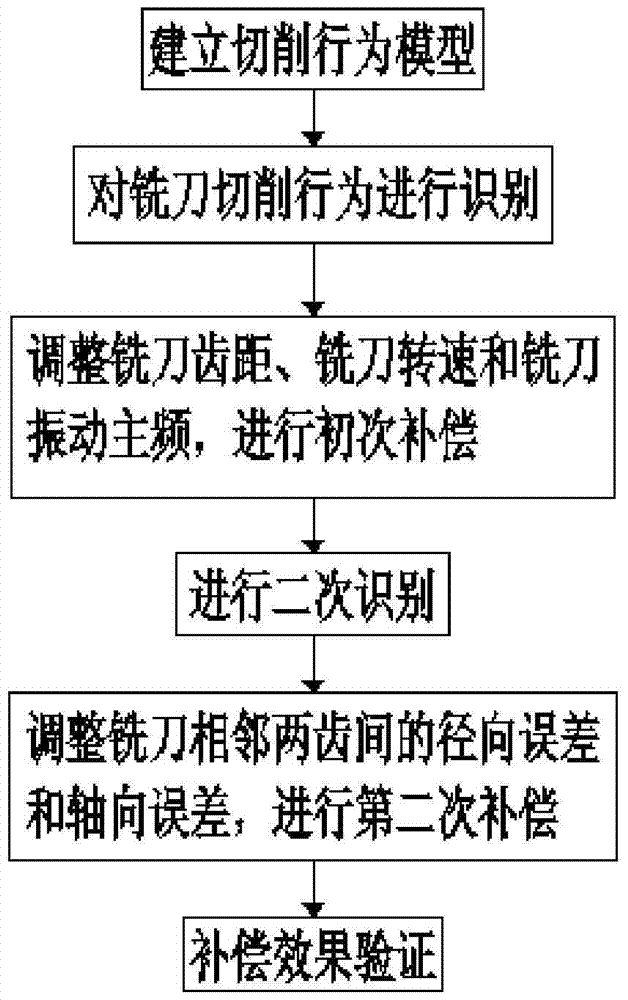

[0056] The specific embodiment of the present invention is described in conjunction with accompanying drawing, the technical solution of the present invention of the present invention is: the compensation method of multi-tooth uneven cutting behavior of high-speed milling cutter, comprises the following steps:

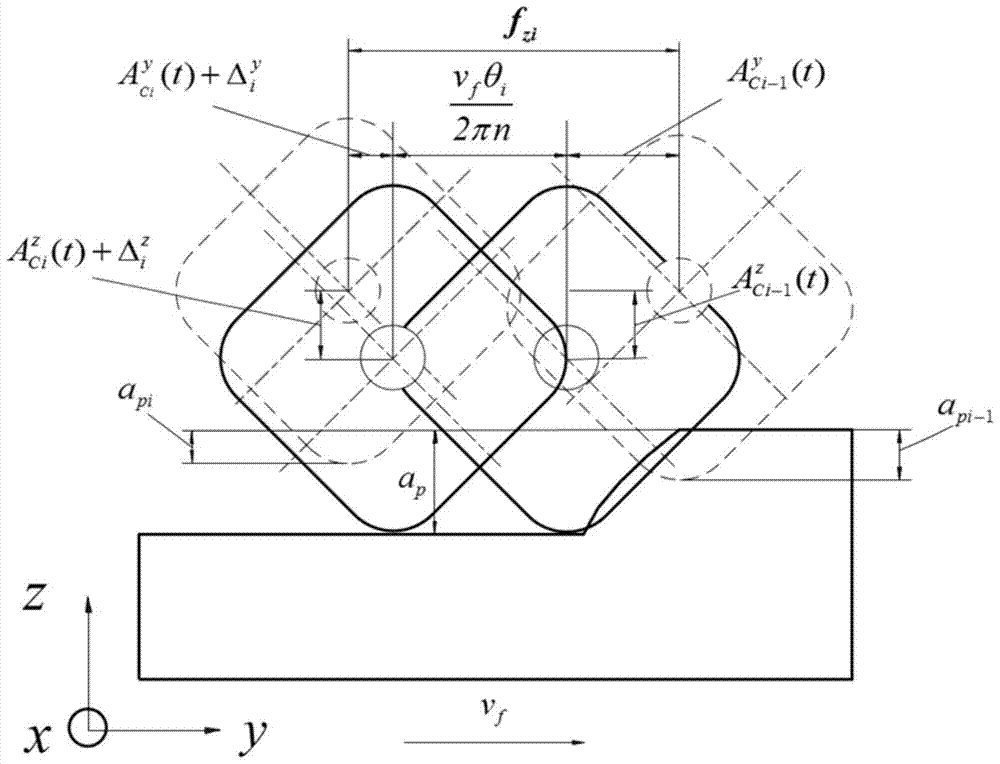

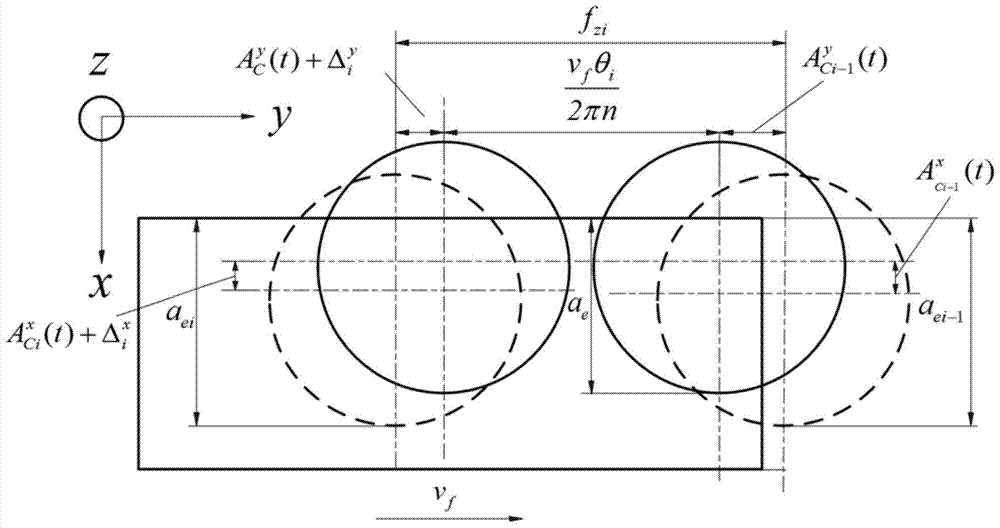

[0057] Step 1. Establish the cutting behavior model of high-speed milling cutter under the influence of cutter vibration and cutter tooth error, specifically:

[0058] Construct the cutting coordinate system of milling cutter teeth, take the specified point on the machine tool as the origin of the coordinate system, take the milling width direction of the high-speed milling cutter as the x-axis, take the milling cutter feed direction as the y-axis, and take the milling cutter's milling depth direction as z axis;

[0059] In this coordinate system, the cutter tooth cutting model under the influence of high-speed milling cutter vibration and cutter tooth error is establi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com