A Method for Analyzing Oil-Water Emulsion Behavior in Near Well Zones and Perforated Blast Holes

A near-well zone, oil-water emulsification technology, applied in wellbore/well components, earthwork drilling, measurement, etc., can solve the problem of energy without direction scalar, etc., and achieve the effect of easy analysis, simple model, and easy access to parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described further below:

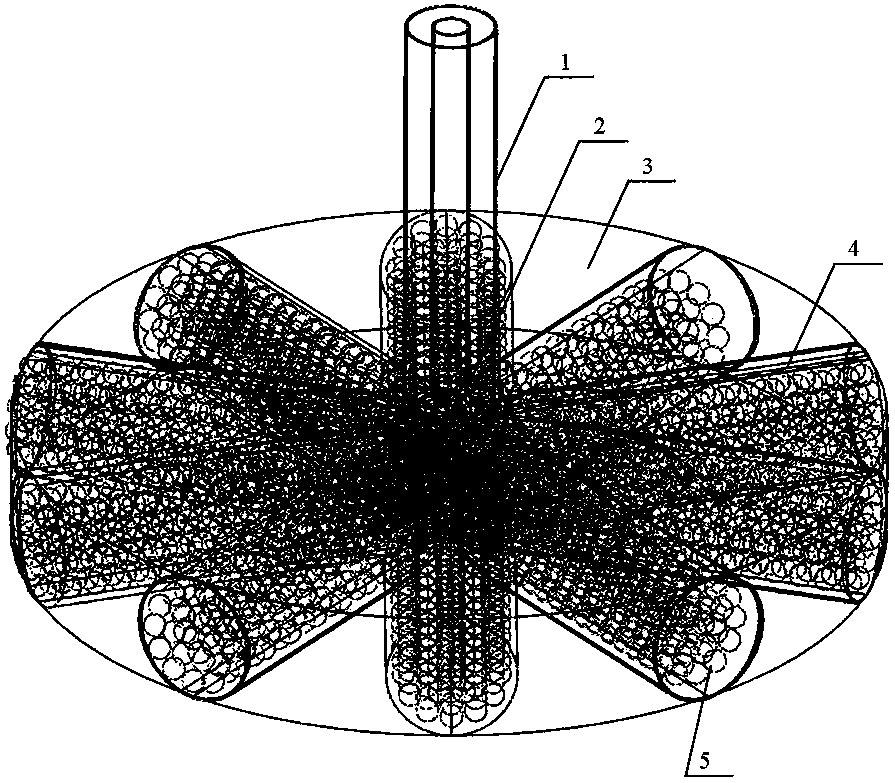

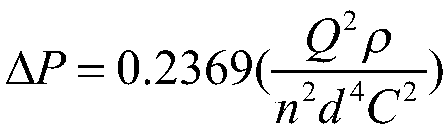

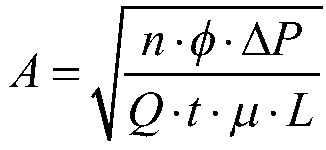

[0027] The method described in the present invention utilizes shear energy to analyze the oil-water emulsification behavior in the near-wellbore zone and the perforated blast hole, and its principle is as follows figure 1 As shown, the oil-water emulsions with different degrees of stability flowing through the radial zone 3 near the wellbore and the perforated blasthole 2 flow into the vertical wellbore 1 to realize subsequent crude oil production and transportation. The radial area 3 of the near-wellbore zone is equivalent to a plurality of equivalent circular pipes 4 filled with reservoir rock particles 5 arranged radially and having the same specifications and sizes. In this way, the flow field shearing in the near-wellbore zone and the perforated blasthole area is equivalent to the flow shearing in the circular pipe that can obtain similar flow field distribution characteristics, which is a theoretical method to de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com