A grain size correction method for structural life analysis of aeroengine discs

A technology of aero-engine and grain size, applied in instrument, geometric CAD, calculation, etc., can solve the problem of low prediction accuracy of probabilistic life model, achieve the effect of quantitative description, improve prediction accuracy, and ensure the accuracy of prediction results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

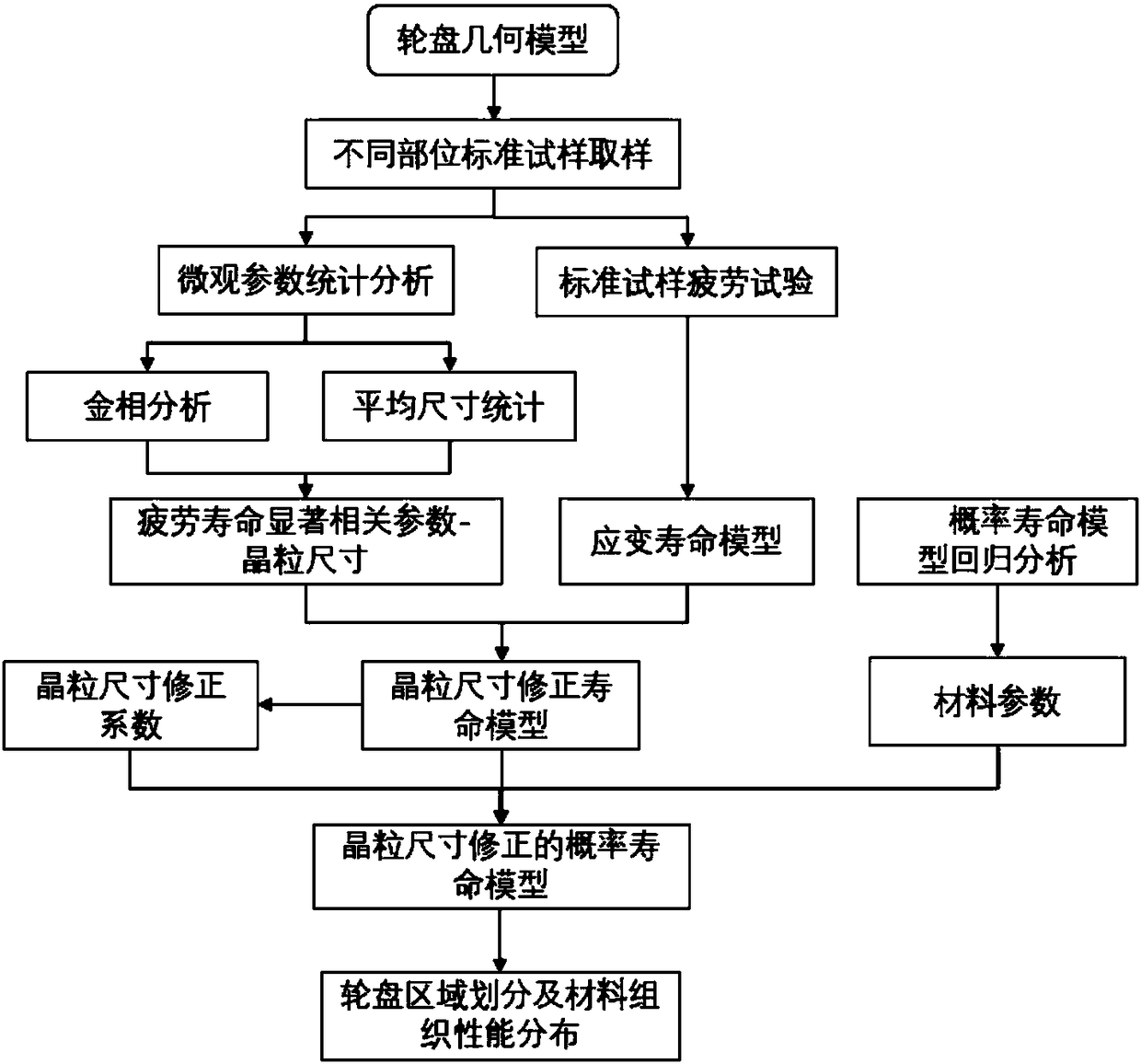

[0021] The technical solution of the grain size correction method for the life analysis of the wheel structure of the present invention will be further described in conjunction with the accompanying drawings.

[0022] Considering the impact of the grain size on the life of the wheel structure, combined with the fatigue life model, the present invention proposes a grain size correction method for the life analysis of the wheel structure. The process is shown in figure 1 .

[0023] Step (1), standard sample sampling of different parts of the wheel: firstly, the finite element analysis of the wheel is carried out, the material properties and deterministic load of the wheel are input, and the detailed three-dimensional stress and strain analysis of the wheel structure is carried out, and the wheel is obtained Analysis results of strain, stress and displacement of the disc structure. Then, for the dangerous parts of the wheel disc structure that may have fatigue failure, the stand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com