Threaded cartridge type manual proportional reversing valve

A proportional reversing valve and threaded cartridge technology, which is applied to valve details, multi-way valves, valve devices, etc., can solve the problems of unable to control the maximum flow rate and poor accuracy, and achieve the effect of preventing injury accidents and preventing misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

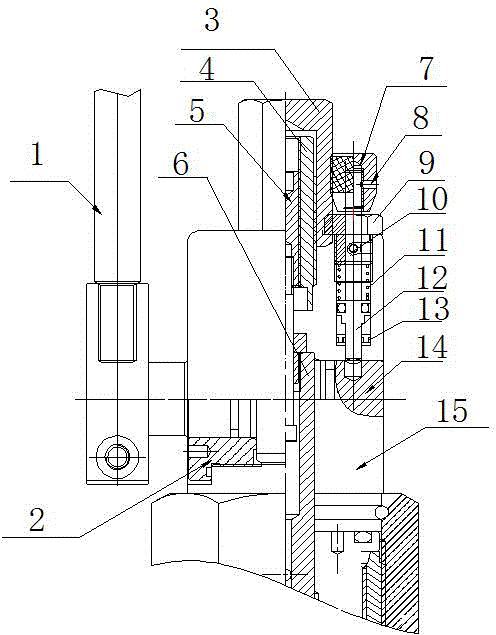

[0012] The present invention will be further described below in conjunction with accompanying drawing:

[0013] A threaded plug-in manual proportional reversing valve, including a handle 1, a valve head assembly 15, the handle 1 is connected and fixed to the transmission shaft 14 through a cap 2, and also includes a limiting device and a locking device. The limiting device It is composed of an upper limit 4, a lower limit 5 and a protective sleeve 3. The groove formed by the upper limit 4 and the lower limit 5 is matched with the raised part of the transmission rod; the valve head assembly 15 is fixed with a nut 9 , the nut 9 is threaded with a knob 7, and the knob 7 is threaded with the locking valve core 12 and fixed by a fastening pin 8.

[0014] The locking spool is provided with a column pin 10; the nut 9 is provided with an "L"-shaped groove matching with the column pin 10; the locking spool 12 is integrally forged by alloy steel; the The lower end of the locking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com