A detection system and detection method for the corrosion degree of steel bars

A steel bar corrosion and detection system technology, applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of instrument interference, limitation, corrosion sensitivity, etc., and achieve the effect of intuitive corrosion results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

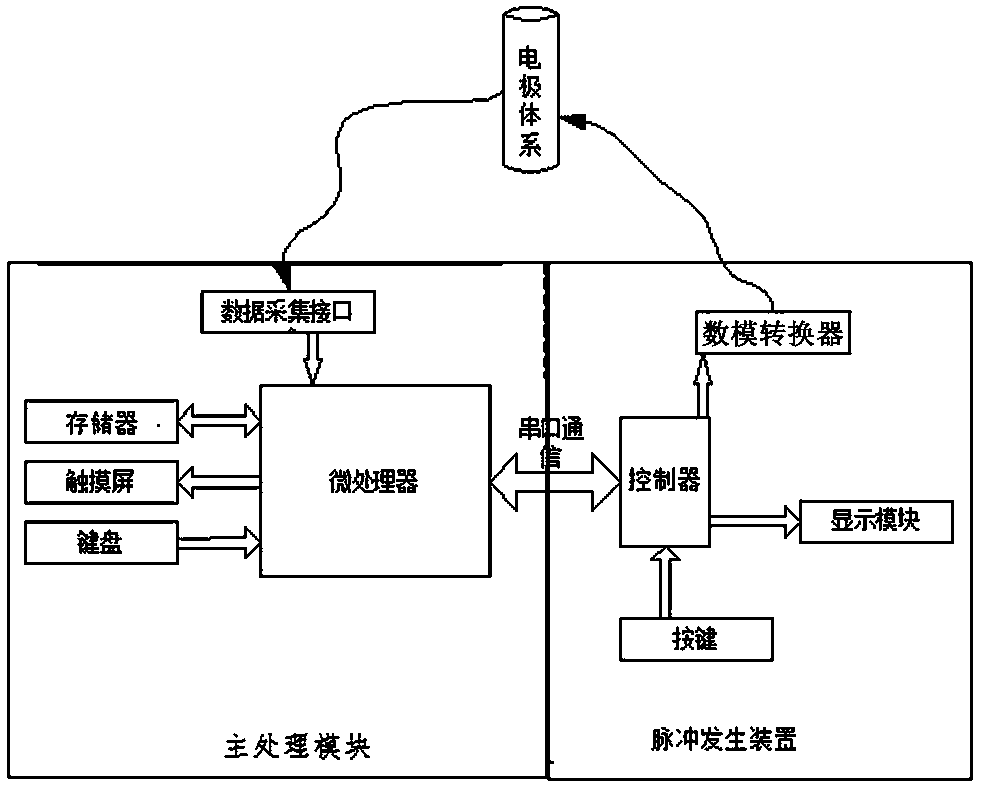

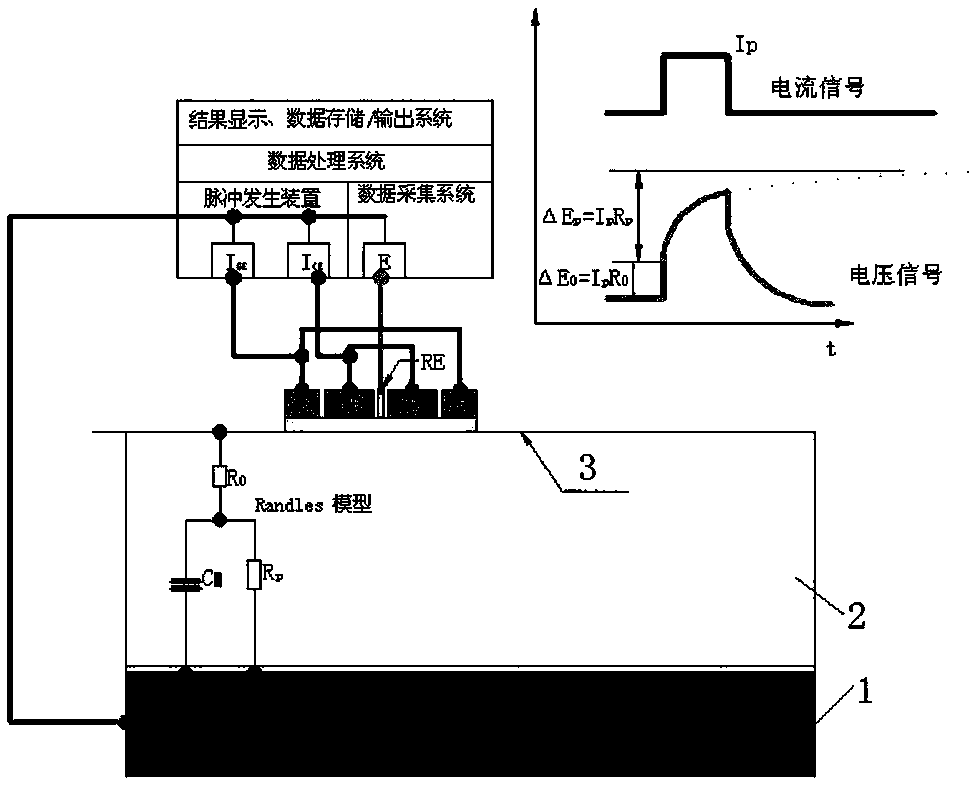

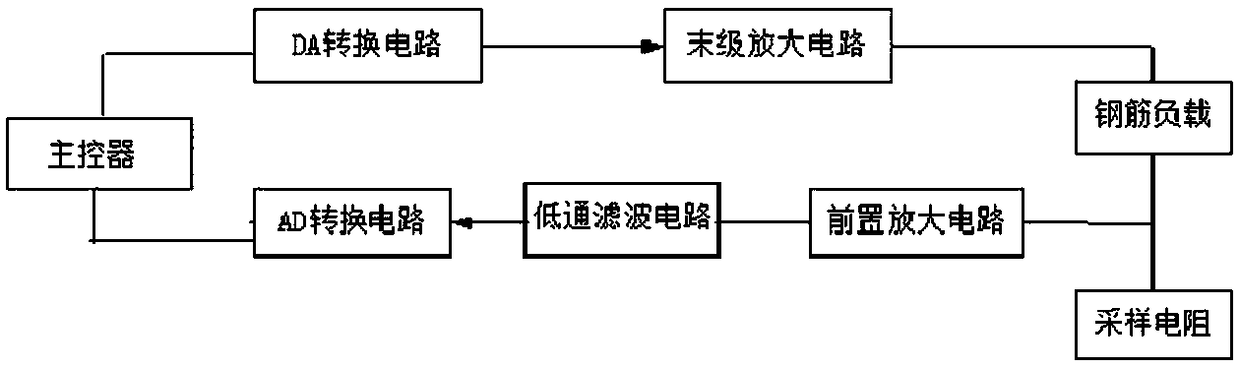

[0033] see figure 1 , a steel bar corrosion detection system, including a test instrument and an electrode system for testing, the test instrument includes a main processing module and a pulse generating device; the main processing module is connected to the pulse generating device; the electrode system for the test A three-electrode system is adopted, including a working electrode WE, a pair of electrodes CE, a reference electrode RE and a guard ring electrode GE; The electrode RE is applied to the concrete system, the pulse polarization current is restricted by the guard ring electrode GE, and the pulse polarization current is limited to the projection area of the counter electrode CE, and the system receives the potential change of the concrete through the data acquisition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com