Rapid measurement method of liquid ammonia content

A measurement method, liquid ammonia technology, applied in the field of liquid ammonia treatment, can solve the problem that the ammonia unloading device has no safety sampling device and filter device, cannot meet the requirements of safe sampling and purification of liquid ammonia, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

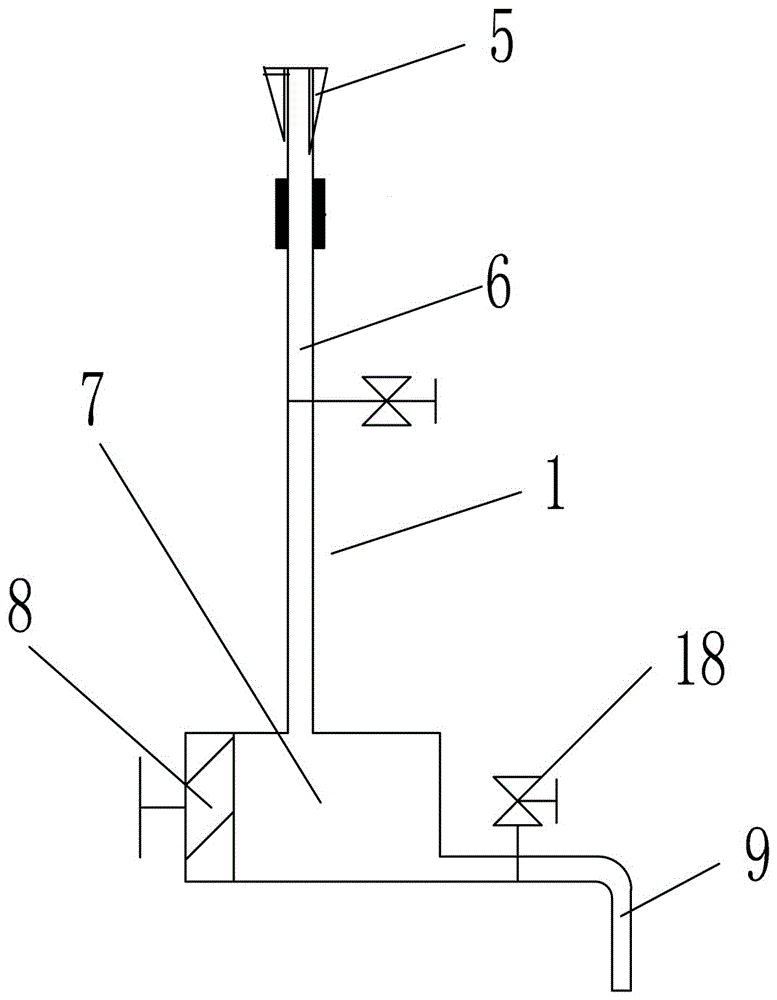

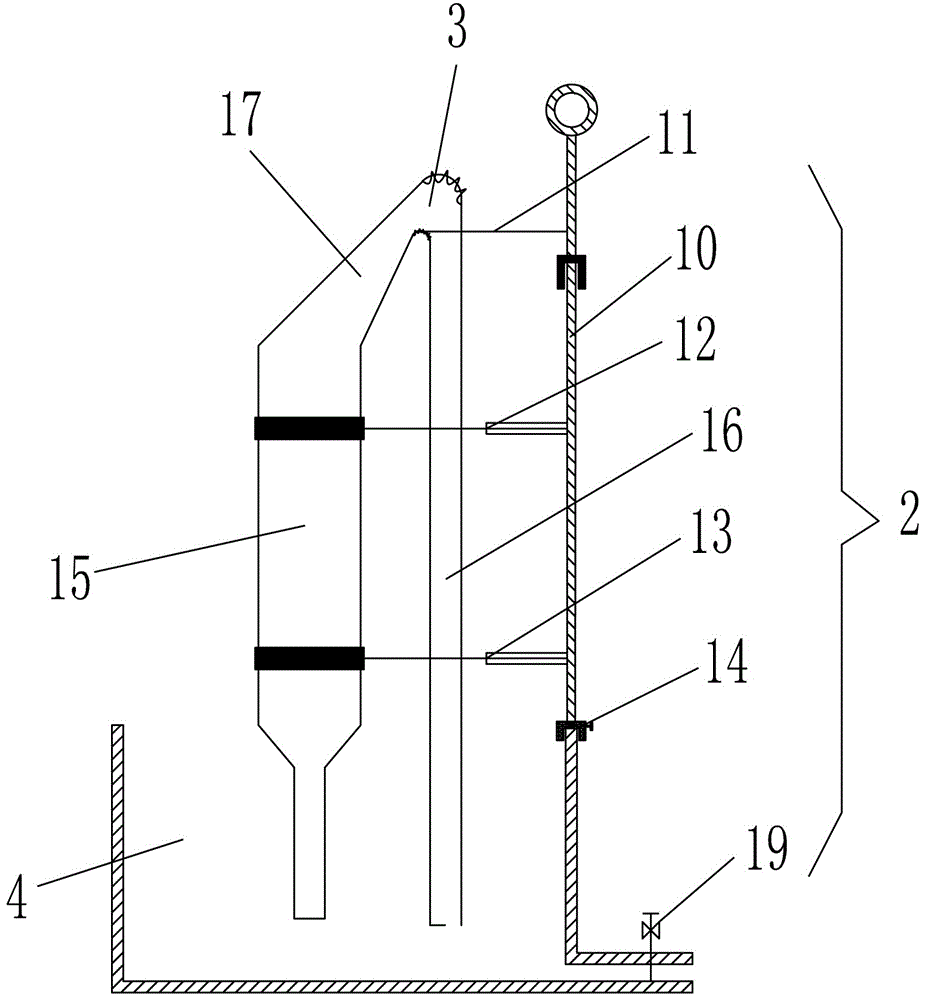

[0041] The following description is merely exemplary in nature and not intended to limit the disclosure, application or use. The specific implementation of the method for quickly measuring liquid ammonia content of the present invention will be further described below in conjunction with the accompanying drawings.

[0042] The rapid measurement method for liquid ammonia content of the present invention realizes the safe and rapid determination of liquid ammonia content through the joint action of constant volume sampling, test tube support with variable direction, evaporation sealing device and sample low-temperature heating.

[0043] Reached following effect by adopting measuring method of the present invention: improve the security of analysis:

[0044] First, through constant volume sampling. Realize safe sampling of liquid ammonia and avoid personal injury to sampling personnel; set up evaporation sealing device to reduce personal injury caused by liquid ammonia during sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com