Small-caliber long-barrel optical lens installation tool and installation method

A technology of optical lenses and installation tools, which is applied in the direction of installation, optics, optical components, etc., can solve the problems of lens installation difficulties and achieve the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

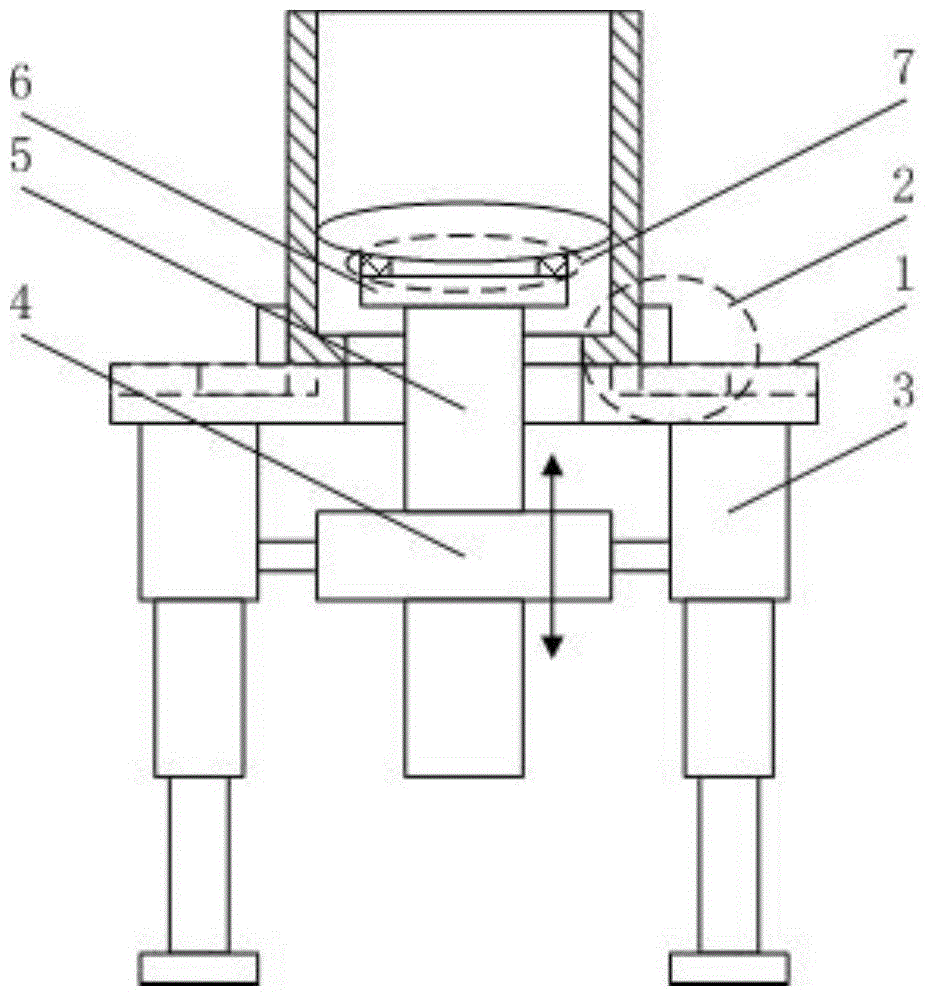

[0031] The small-diameter long lens barrel optical lens lens mounting tool of the present embodiment, the structural representation is as figure 1 shown. The small-diameter long lens barrel optical lens lens installation tool includes a support surface 1 with a circular through hole in the middle, a plurality of locking ends 2 arranged on the top of the support surface 1, and support legs 3 arranged at the bottom of the support surface 1;

[0032] The locking end 2 moves along the radial direction of the circular through hole of the supporting surface 1;

[0033] The supporting leg 3 is a multi-level telescopic rod structure with hole-shaft clearance fit, and in each level of hole-shaft fit structure, the shaft structure is provided with a scale;

[0034] In the uppermost hole shaft matching structure of the support leg 3, the hole structure is connected with a handle end 4, and a lift platform 5 moving in the vertical direction is arranged in the middle of the handle end 4. ...

specific Embodiment 2

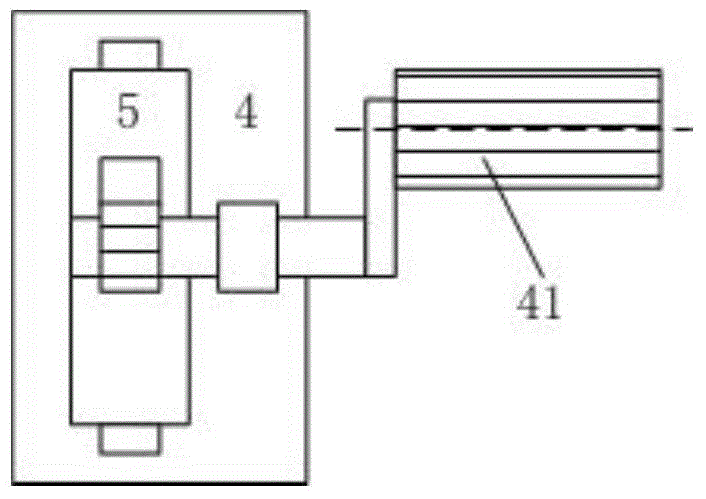

[0040] The small-diameter long lens barrel optical lens lens installation tool of the present embodiment, on the basis of the specific embodiment one, further defines that the handle end 4 is provided with a hand handle 41, and the hand handle 41 is connected with the handle end 4 through a bearing. The outer end of the crank handle 41 is provided with a hand end, and the inside is provided with a gear; the side or the middle of the lifting platform 5 is provided with a tooth bar matched with the gear; shaking the manual handle 41 can make the lifting platform 5 move up and down. The connection relationship between the handle end 4 and the lifting platform 5 is as follows: figure 2 shown in figure 2 Among them, the upper and lower positions of the lifting platform 5 are drawn as guide rails.

specific Embodiment 3

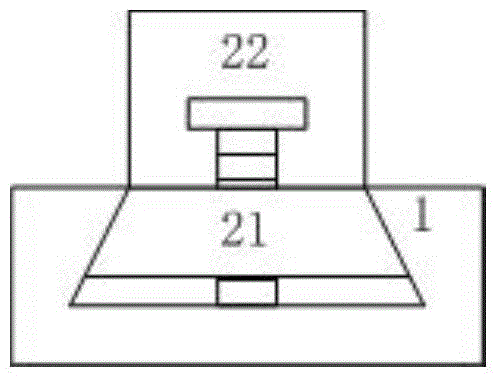

[0041] The small-diameter long lens barrel optical lens lens mounting tool of this embodiment, on the basis of the specific embodiment 1, further defines that the cross section of the lens support end 6 is circular, and the radius is not smaller than the cross section of the lifting platform 5, and smaller than the lens barrel opening. An annular sponge pad 7 is arranged on the top of the lens support end 6 , and the outer circumference of the sponge pad 7 coincides with the circumference of the lens support end 6 .

[0042] The setting of the sponge pad 7 can not only avoid hard contact between the lens and the lens support end 6, causing the lens support end 6 to damage the lens; and the sponge pad 7 is designed as a ring, which can accept non-planar lenses.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap