Paste thickener bottom flow circulation homogenizing device

A paste thickener and homogenization technology, which is applied to chemical instruments and methods, settling tanks, separation methods, etc., can solve the problems of the thickener pressing and harrowing down, unable to control high-concentration underflow, etc., to achieve simple equipment and solve underflow The effect of loop control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

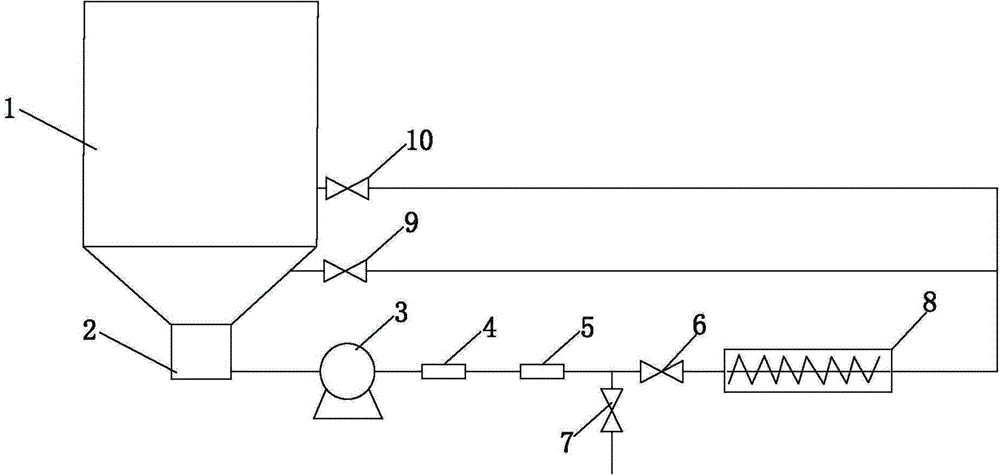

[0020] Such as figure 1 As shown, after the low-concentration full tailings mortar is thickened by the paste thickener 1, the high-concentration full tailings bottom flow is discharged through the collection well 2, and the bottom flow pump 3 is transported to the thickener through the circulation pipeline for continuous circulation.

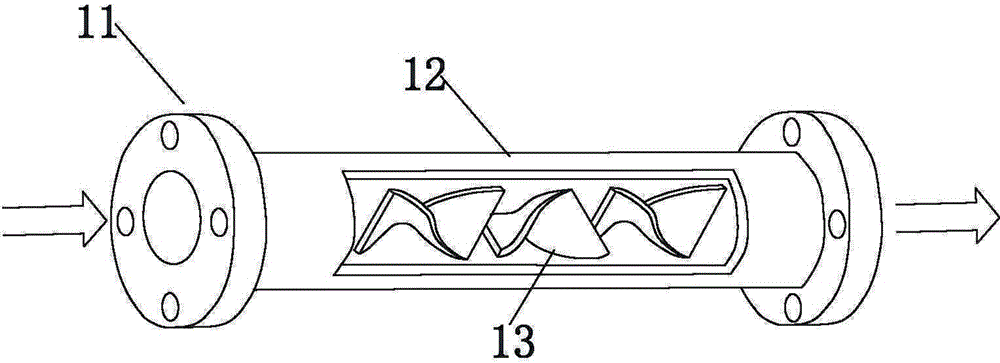

[0021] During the transportation process, the underflow concentration value is obtained by the nucleon concentration meter 4. When the underflow concentration is 69% to 71%, adjust the speed of the underflow pump 3 so that the reading of the flowmeter 5 is 50m 3 / h~100 3 / h, close valve 2 7, open valve 1 6, so that the bottom flow of the whole tailings flows through the homogenizer 8, the inner diameter of the pipeline 12 of the homogenizer 8 is 220 mm, through the stirring blade 13, open the valve 3 9, close the valve Four 10, realize the low-level homogenization cycle of the underflow concentration. In this process, the reading of the data o...

Embodiment 2

[0024] Such as figure 1 As shown, after the low-concentration full tailings mortar is thickened by the paste thickener 1, the high-concentration full tailings bottom flow is discharged through the collection well 2, and the bottom flow pump 3 is transported to the thickener through the circulation pipeline for continuous circulation.

[0025] During the conveying process, the underflow concentration value is obtained by the nucleon concentration meter 4, and when the underflow concentration is 71% to 75%, adjust the speed of the underflow pump 3 so that the reading of the flowmeter 5 is greater than 100 3 / h, close valve two 7, open valve one 6, make the whole tailings underflow flow through in the homogenizer 8, the inner diameter of the pipeline 12 of the homogenizer 8 is 250mm, the underflow is stirred and homogenized by the stirring blade 13, Close valve three 9 and open valve four 10 to realize the high-level homogenization cycle of underflow concentration. In this proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com