Missile wing single side wing face folding mechanism

A technology of folding mechanism and elastic wings, which is applied to projectiles, offensive equipment, weapon types, etc., can solve the problems of large occupation space and high deployment synchronization, achieve small installation space, small transmission clearance and joint movement clearance, and save ammunition. The effect of body space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The following examples are only used to illustrate the present invention, and are not intended to limit the protection scope of the present invention.

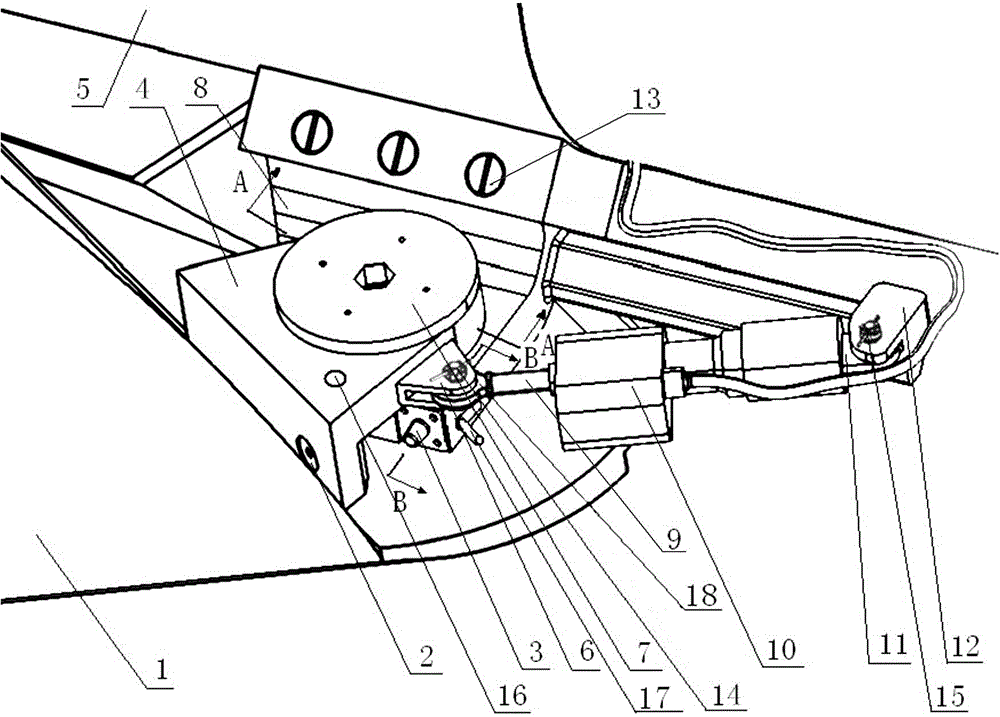

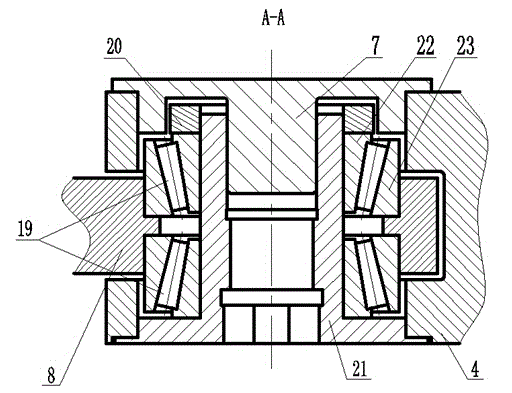

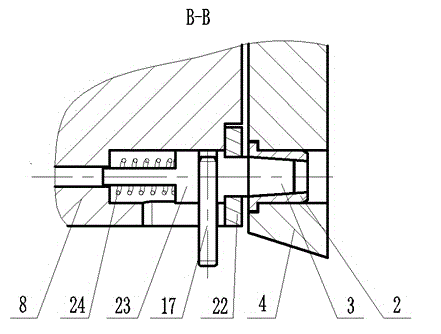

[0017] figure 1 As shown, the wing single-side wing surface folding mechanism of the present invention includes an adapter 8, a wing joint 4, a bearing 19, a wing rotating shaft 21, a pre-tightening nut 20, a tightening nut 7, an actuating device 10 and a spring locking pin 3. The adapter 8, the wing joint 4 and the bearing 19 are assembled into a revolving pair through the wing shaft 21, the pre-tightening nut 20 and the fastening nut 7. The body 5 is connected by bolts, and the connection points and the number of connecting bolts can be adjusted according to the load conditions of different missile wings. The wing joint 4 is integrally formed with the wing 1 or connected to the wing 1 by faste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com