A method for simulating and predicting the suspension velocity of granular materials

A technology of granular material and speed, applied in the fields of agricultural machinery, pneumatic conveying, and fluidized bed, it can solve the problem of difficulty in measuring fluid flow rate, and achieve the effect of avoiding multiple purchases and repeated tests, and reducing test costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

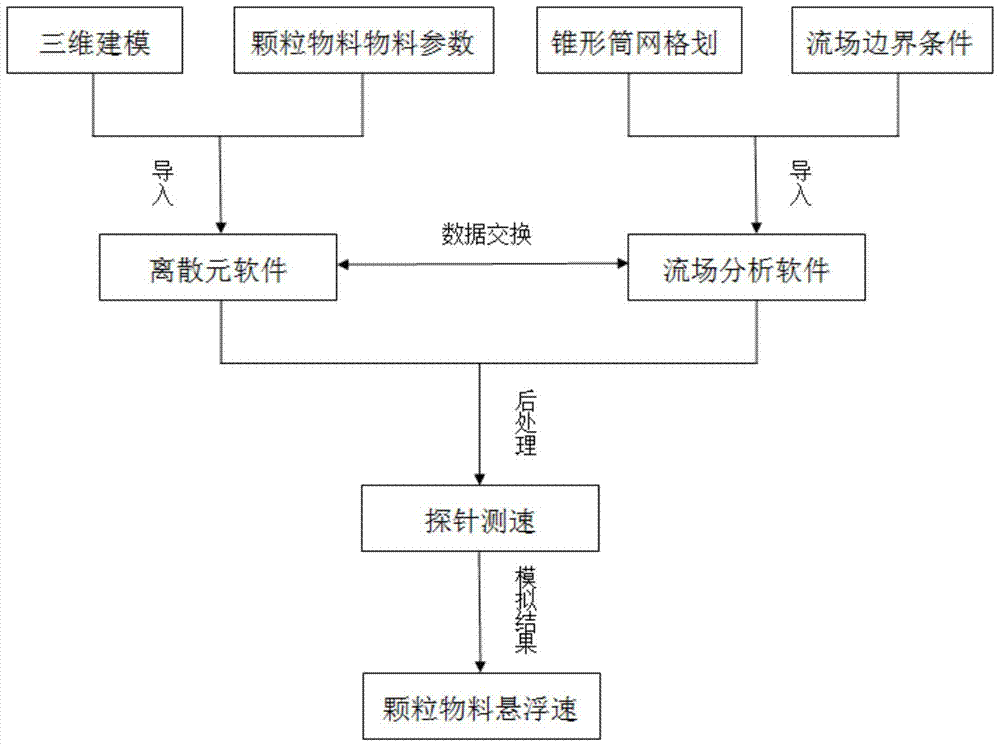

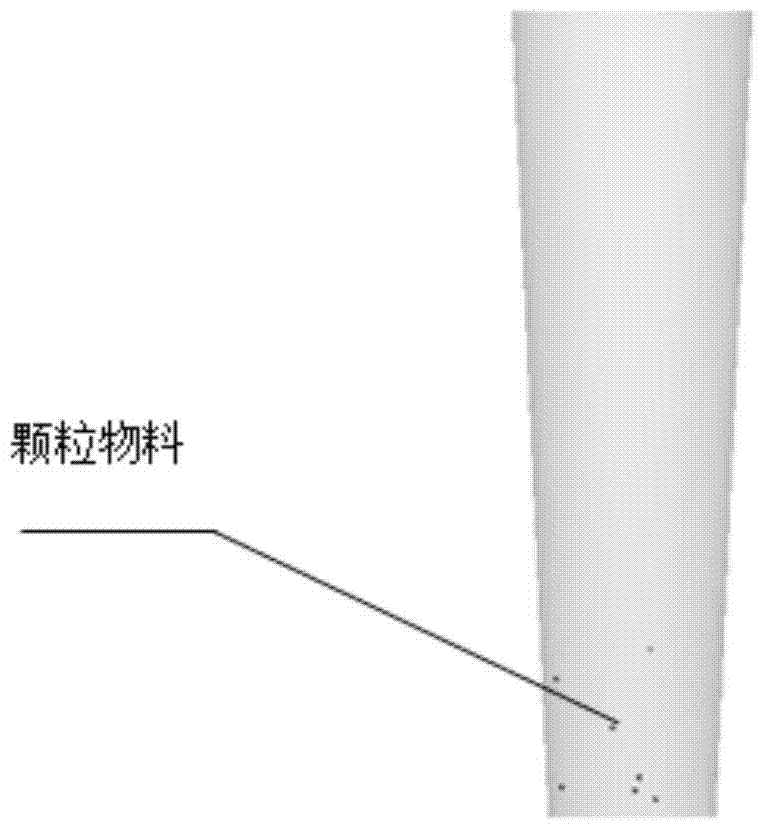

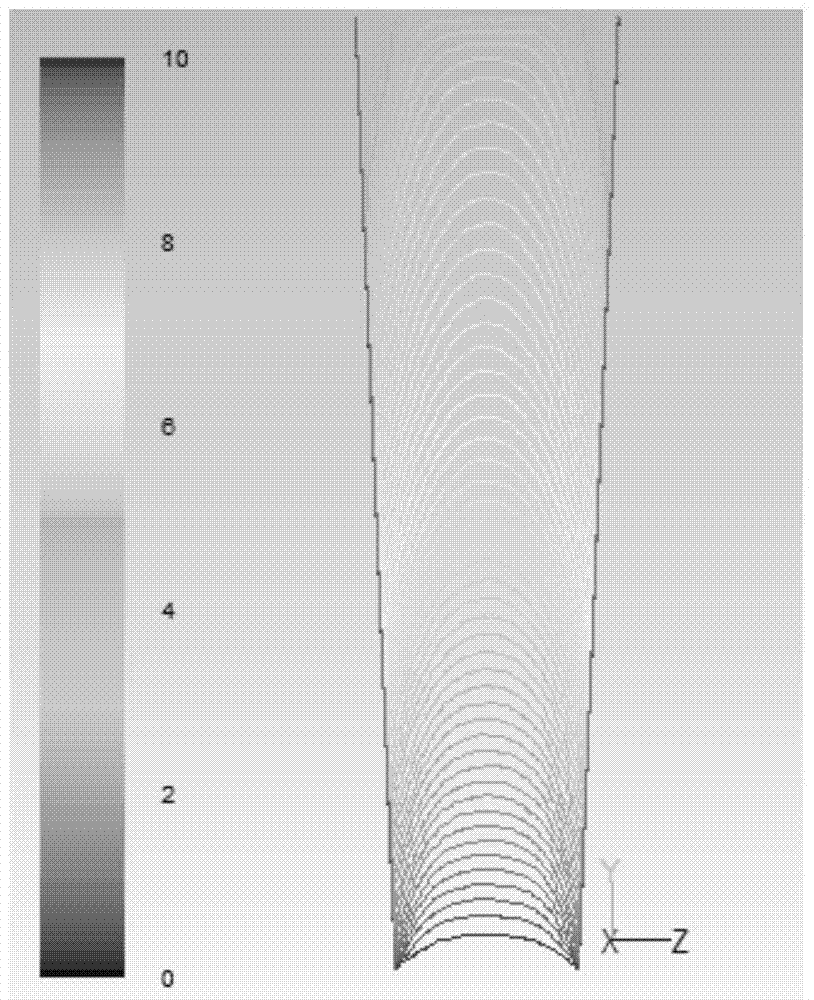

[0032] Embodiment 1: as Figure 1-5 As shown, a method for simulating and predicting the suspension velocity of granular materials, first simulates the suspension test bench through three-dimensional modeling, measures the size of the conical cylinder of the key part of the test bench, and performs three-dimensional modeling of the conical cylinder according to the measured actual data, through The physical parameters of the granular material are measured, and the obtained 3D model of the conical cylinder and the physical parameters of the granular material are imported into the discrete element analysis software to complete the establishment of the particle field; the conical cylinder model is imported into the meshing software for meshing division; import the meshed conical cylinder model into the fluid mechanics software, set the boundary conditions of the flow field, and complete the establishment of the flow field; set the time step of the particle field simulation process...

Embodiment 2

[0046] Embodiment 2: as Figure 1-5 As shown, a method for simulating and predicting the suspension velocity of granular materials, taking the rare Chinese herbal medicine Panax notoginseng seed particles in Yunnan as an example, first simulates the suspension test bench through three-dimensional modeling, and measures the size of the conical cylinder of the key part of the test bench. The actual data is used for three-dimensional modeling of the conical cylinder, and the physical parameters of the granular material are obtained through measurement. The obtained three-dimensional model of the conical cylinder and the physical parameters of the granular material are imported into the discrete element analysis software to complete the establishment of the particle field; Import the cylinder model into the grid division software for grid division; import the meshed conical cylinder model into the fluid mechanics software, set the boundary conditions of the flow field, and complete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com