High-speed railway track segmented measurement data smooth connecting method

A technology for segmented measurement and high-speed railways, which is used in tracks, measuring instruments, track maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

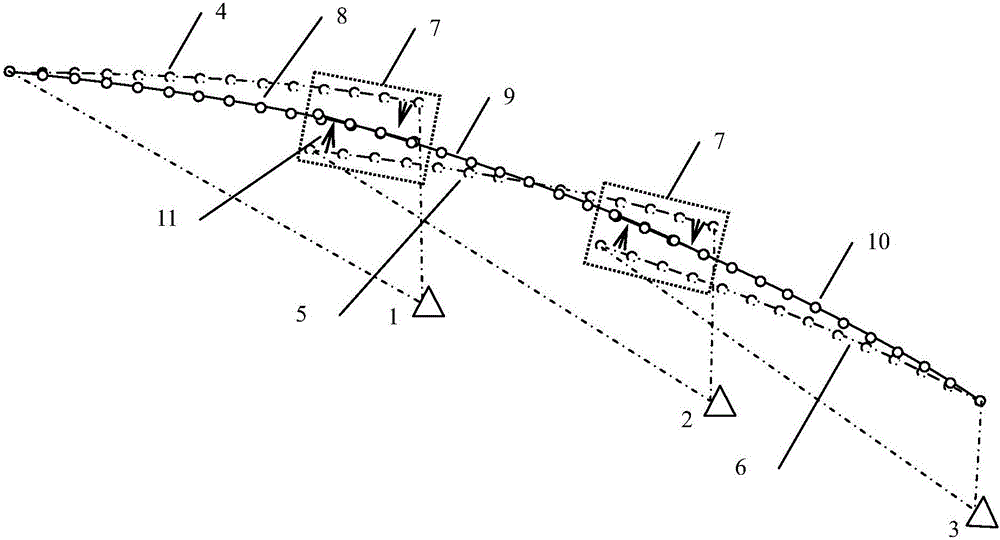

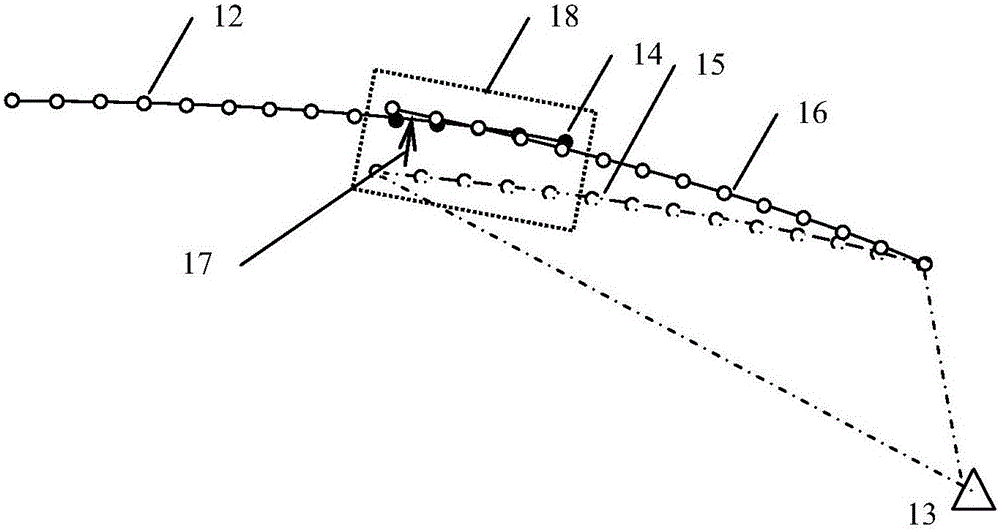

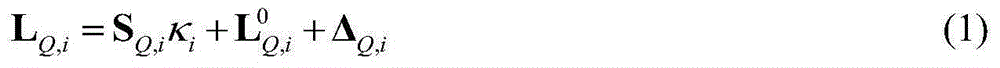

[0027] During the track measurement of high-speed railway, according to the characteristics of high-speed railway CPⅢ control network arranged in pairs at intervals of 50-70m, in order to ensure the measurement accuracy of the three-dimensional precise measurement system of the track, the track geometric state measuring instrument or track inspection instrument needs to carry out the whole station at intervals The instrument station is set up, and the track detected by the adjacent station requires 6 to 10 sleepers or an overlapping area of a section of the line. When the measurement data of the station are obtained, the smooth connection method can be used for processing. The present invention will be further described now in conjunction with accompanying drawing. However, it should be emphasized that the following embodiments are only exemplary and not intended to limit the scope and application of the present invention.

[0028] When the number of stations n>1, that is, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com