A repeatable test method for automatic verification system of direct-in three-phase smart energy meter

An automatic verification and smart energy meter technology, which is applied in the field of instrumentation and electrical measurement, can solve the problems of long calibration cycle time, heavy manual workload, and low work efficiency, achieving scientific design, ensuring the transmission of electric energy value, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

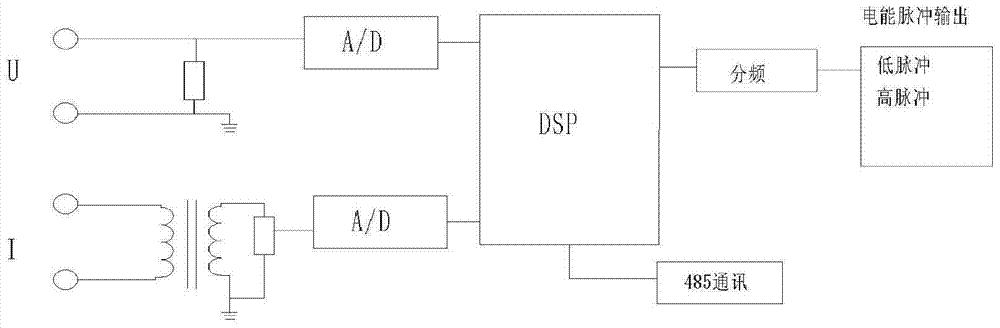

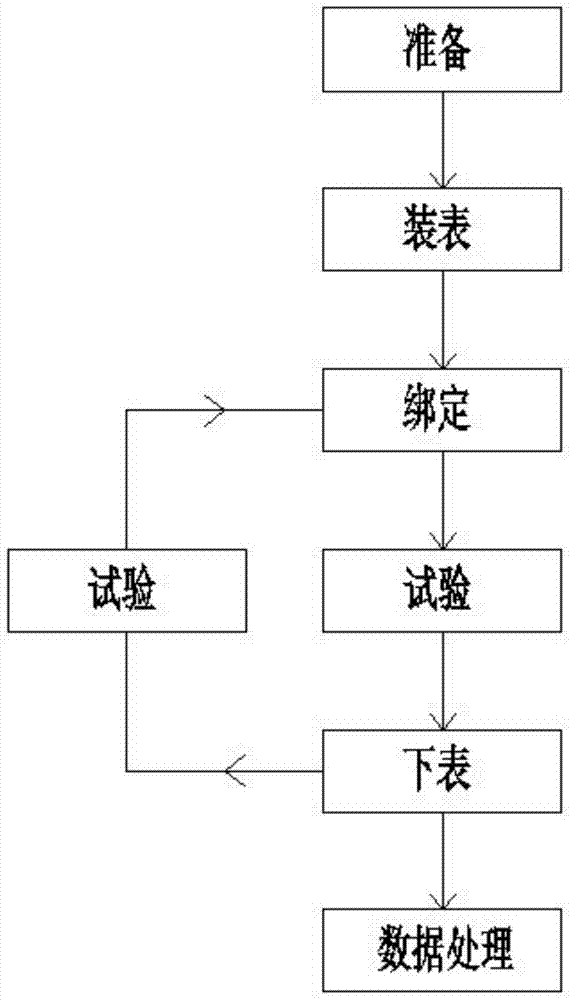

[0024] A repetitive test method for an automatic verification system of a direct-in three-phase smart electric energy meter. The verification process steps on the automatic assembly line verification system are as follows:

[0025] ⑴Preparation: Set the standard electric energy meter of the direct-in three-phase smart electric energy meter. The accuracy of the standard electric energy meter is 0.02, while the electric energy meter used by ordinary residents, that is, the normal task electric energy meter to be tested is level 2, and the accuracy of the standard electric energy meter is Much higher than the task energy meter;

[0026] Make a special barcode for the standard electric energy meter to di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com