Three pipe combination type emergency floating breakwater wave removal unit

A rapid-floating, breakwater technology, applied in the direction of breakwaters, jetties, embankments, etc., can solve problems such as economic losses, great threats to port security, frequent occurrence of disasters, etc., and achieve improved wave dissipation characteristics, good wave dissipation effects, and fast assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

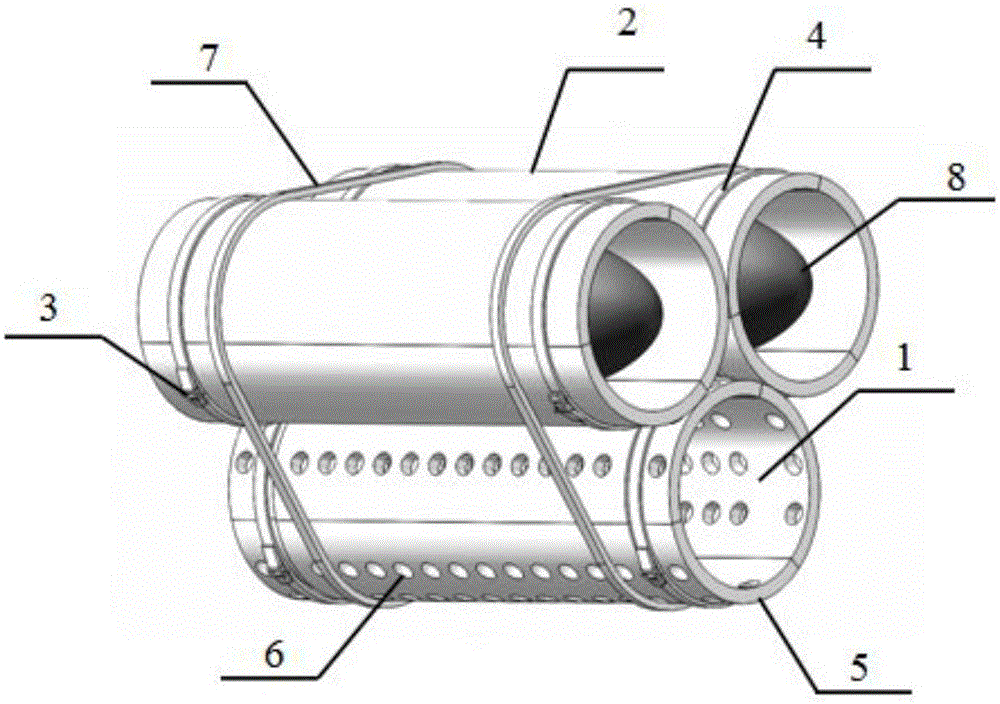

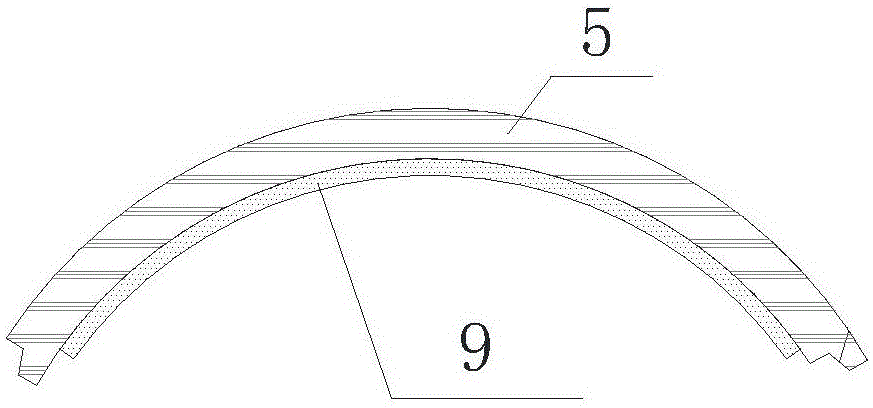

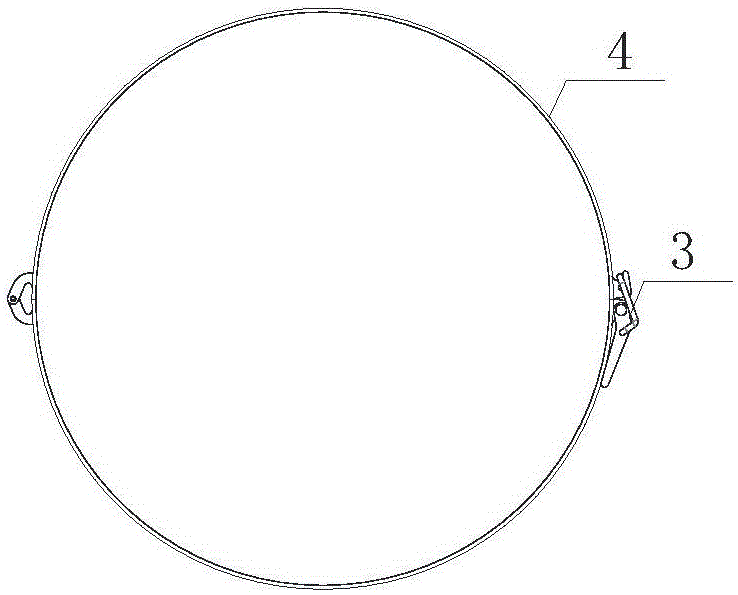

[0017] A three-pipe combined emergency floating breakwater wave dissipation unit is composed of a hollow type wave dissipation pipe 1 and two air bag type wave dissipation pipes 2, a hollow type wave dissipation pipe 1 at the bottom and two airbag type wave dissipation pipes at the top The airbag-type wave-dissipating pipes 2 are arranged in a triangle and are fixed by two triangular fastening frames 7 with quick locks 3. The hollow-type wave-dissipating pipe 1 is assembled by three 120° arc-shaped PVC plates 5 It has a cylindrical structure, and the two PVC plates 5 are connected by a staggered opening, the staggered opening is an inverted trapezoid, and through holes 6 are evenly distributed on the PVC plates, and the three 120° arc-shaped PVC plates 5 are formed by two belt The ring-shaped fastening frame 4 with the quick lock 3 is fixed; the airbag-type wave-dissipating pipe 2 is assembled into a cylindrical structure by three 120° arc-shaped PVC plates 5, and a gap is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com