Impact resisting check valve

A check valve, anti-shock technology, applied in the direction of control valve, valve device, functional valve type, etc., can solve the problems of short service life of the check valve, damage to the sealing surface, valve leakage, etc., to avoid frequent repairs or maintenance, The effect of prolonging the service life and saving cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

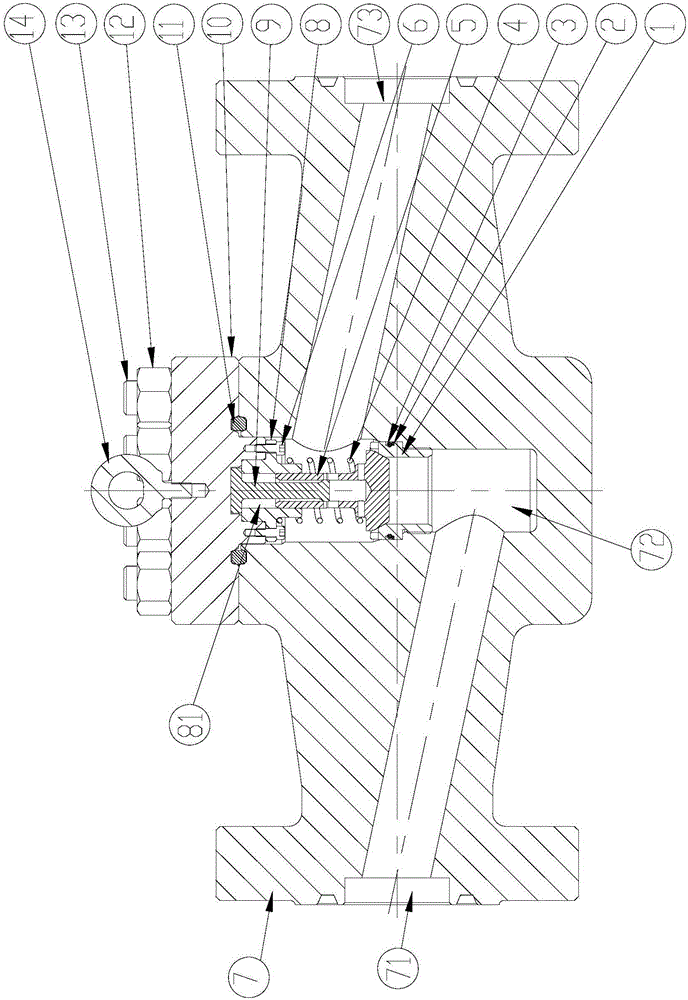

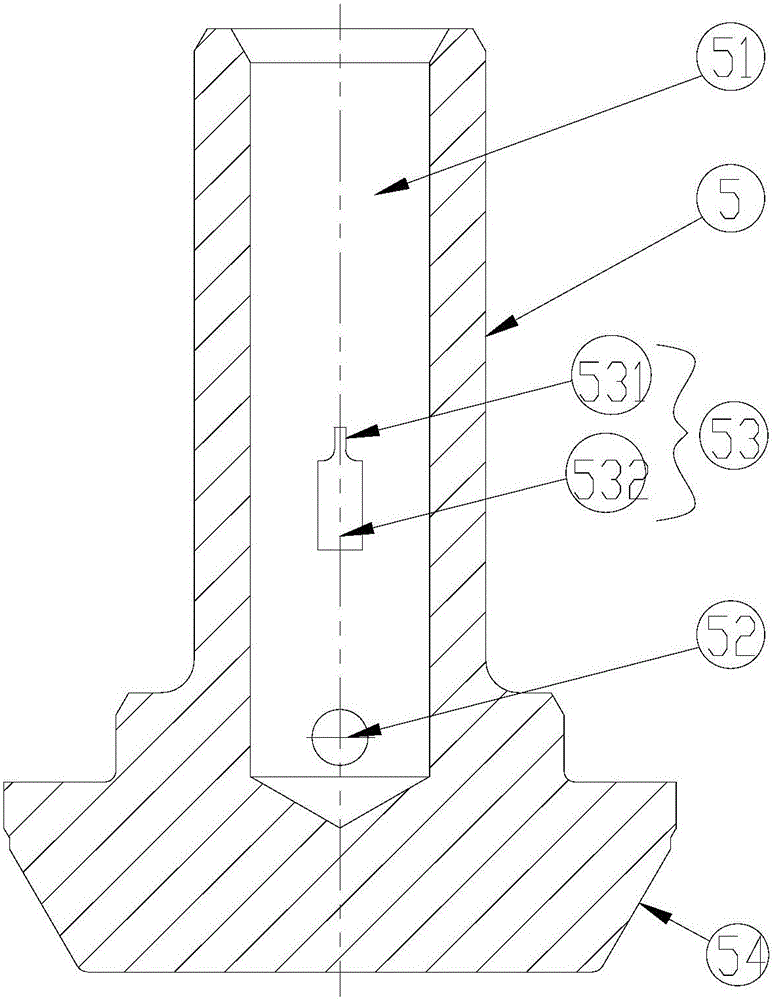

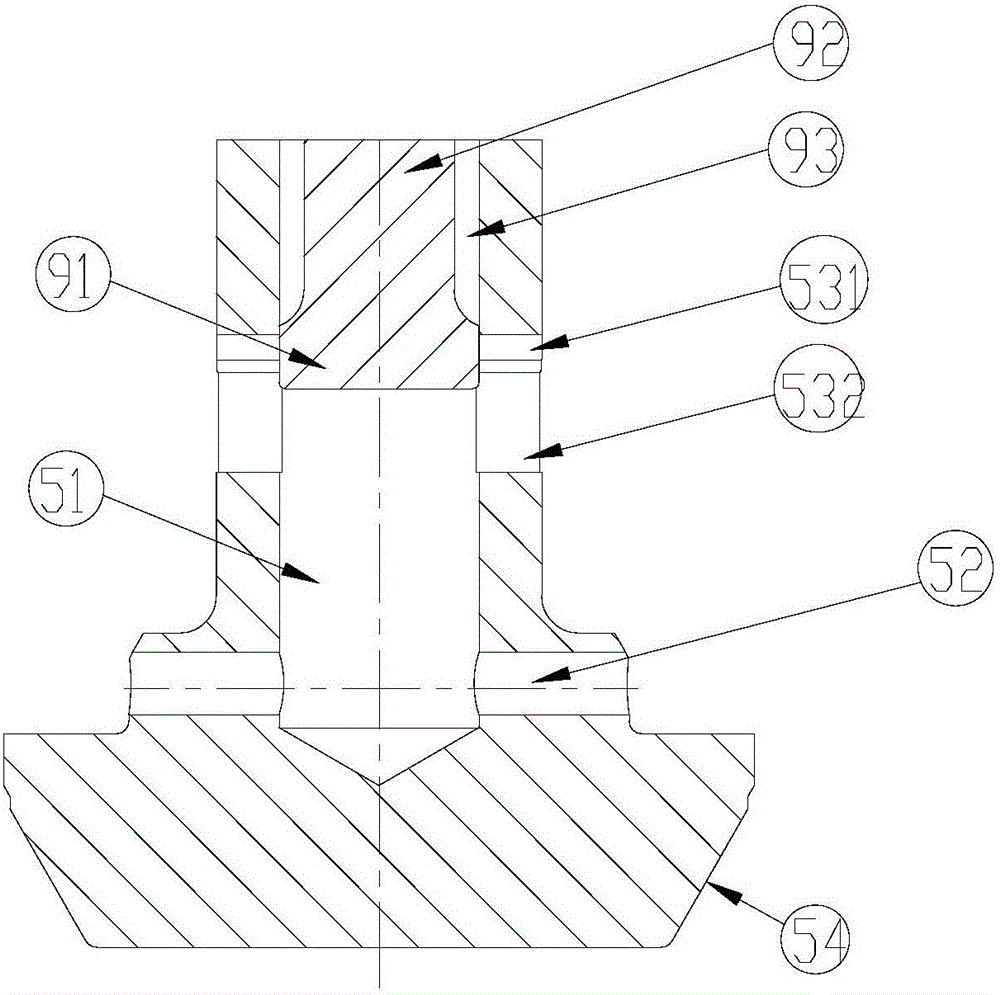

[0031] see Figures 1 to 5 , an anti-shock check valve, including a valve body 7, a valve seat 1, a valve disc 5, an elastic member 4 and a valve cover 10.

[0032] The valve body 7 has a liquid inlet passage 71 , a middle chamber 72 and a liquid outlet passage 73 connected thereto. The valve seat 1 is screwed into the middle chamber 72 and sealed by the retaining ring 2 and the O-ring.

[0033] The valve disc 5 is set on the valve seat 1 to move up and down, and the valve disc 5 cooperates with the valve seat 1 to open and close the middle cavity, and the elastic member 4 is set on the valve disc 5 so that the valve disc 5 has a tendency to close to the valve seat 1 . In this embodiment, the elastic member 4 is a spring.

[0034] The valve cover 10 is fixed on the valve body 7 through nuts 12 and studs 13 , and the valve cover 10 is close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com