Ladle hooking device for bonded slag of steel ladle and machining method of ladle hooking device

A bag hooker and steel technology, applied in the field of sticky slag baggers, can solve the problems of difficulty in removing the iron and steel bag sticky slag, small contact surface, low efficiency, etc., and achieves convenient process forming, rapid hooking and simple manufacturing process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

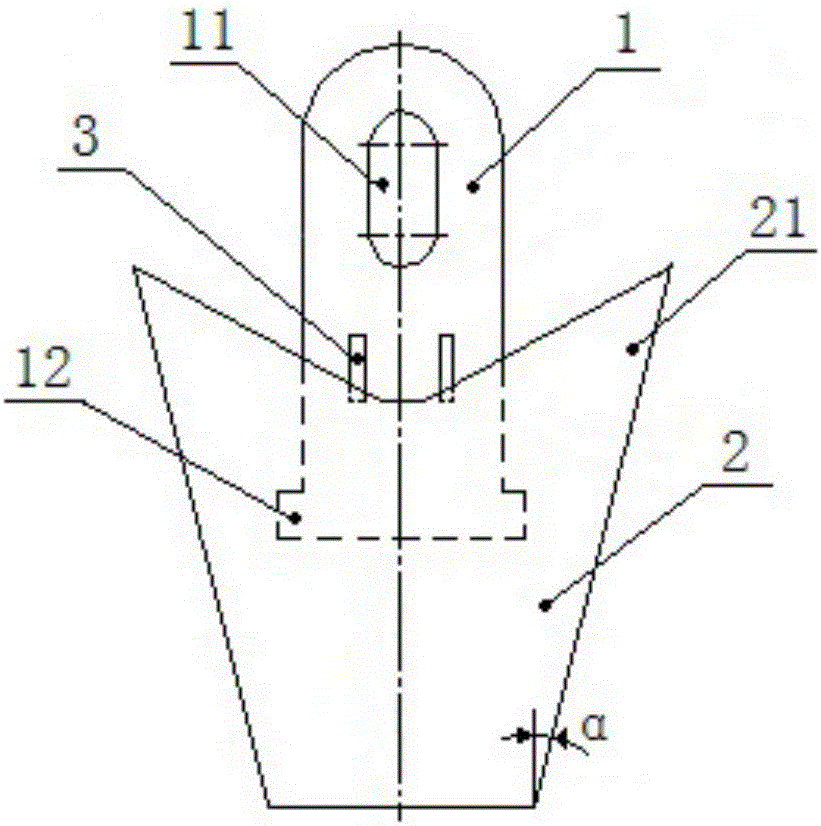

[0016] Figure 2a Shown is a schematic front view of the structure of the present invention.

[0017] Figure 2b Shown is a schematic top view of the structure of the present invention.

[0018] The present invention includes a pull rod 1 and a hook main body 2 .

[0019] An elongated rope-threading hole 11 is provided in the middle of the upper part of the pull rod 1 , and a stepped platform 12 is provided at the bottom of the pull rod 1 .

[0020] The hook main body 2 is in the shape of a truncated square with a large top and a small bottom, and hook teeth 21 are provided at the four corners of the upper part.

[0021] The included angle of the outside slope of the truncated square cone is α, which is specifically determined according to the shape of the steel ladle, so that it fits closely with the steel ladle, and the hook teeth 21 can firm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com