Rolls, roll storage racks and cutting devices

A technology for storage racks and reels, which is applied in the directions of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of copper foil surface wrinkling, etc., and achieve the effect of high switching efficiency and simple fastening method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention are described in detail below:

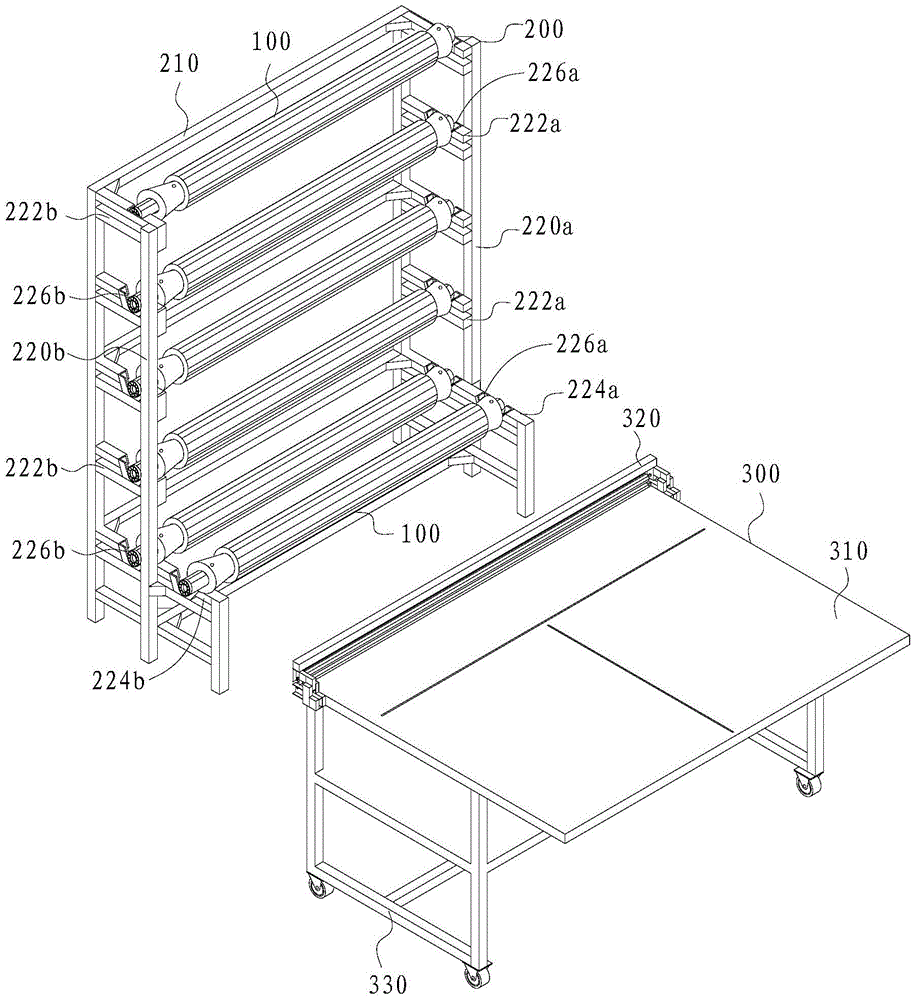

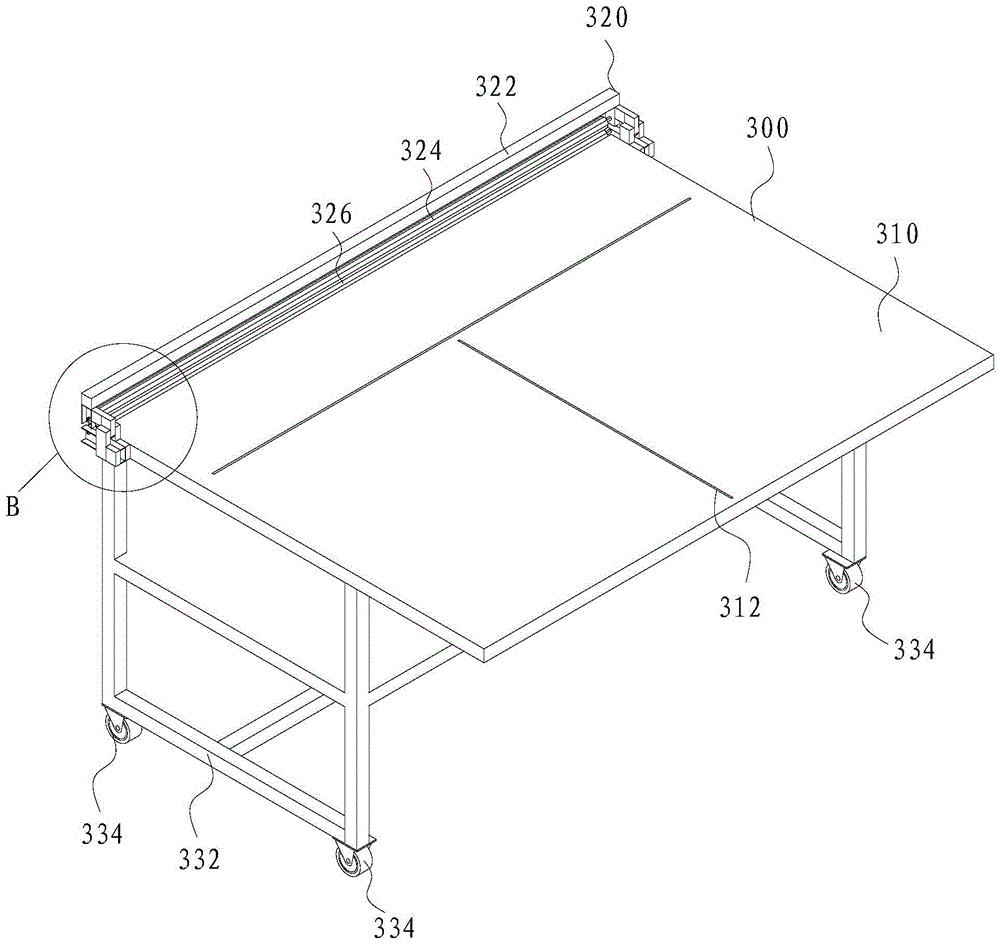

[0037] Such as figure 1 As shown, the present invention provides a cutting device, which includes a roll storage rack 200 and a cutting table 300 located on one side of the roll storage rack 200 . The cutting table 300 includes a platen 310, a support frame 330 supporting the platen 310, and a pressing device 320 arranged on the side of the platen 310. 100 parallel correspondences. The material (copper foil roll 130 (or PP roll)) placed on the roll storage rack 200 on the roll 100 can be pulled out, stretched to the cutting table 300 and then flattened by the pressing device 320 before proceeding cut.

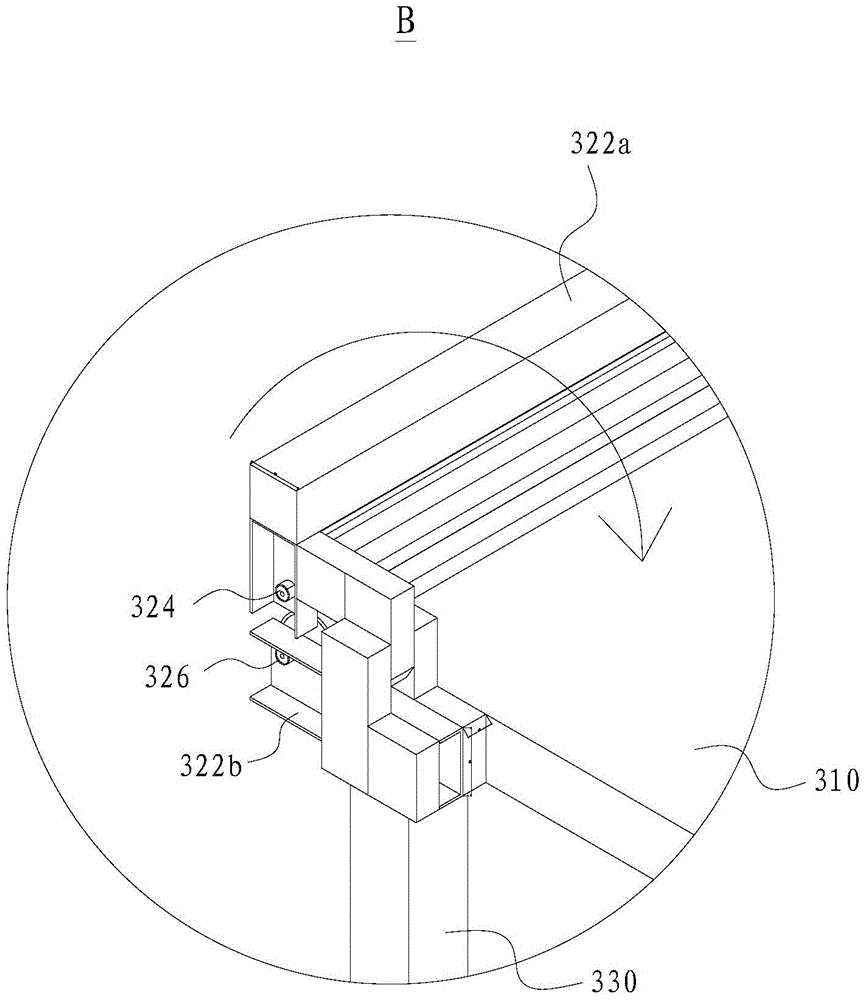

[0038] The pressing device 320 includes a pressing bracket 322 arranged on the platen 310, a first roller 324 and a second roller 326 which are arranged in parallel on the pressing bracket 322 and are close to each other, and are arranged on the pressing bracket 322 and the second roller 326. A gap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com