Test body for determining rotation errors of a rotating apparatus

A technology of rotation device and rotation error, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve problems such as cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

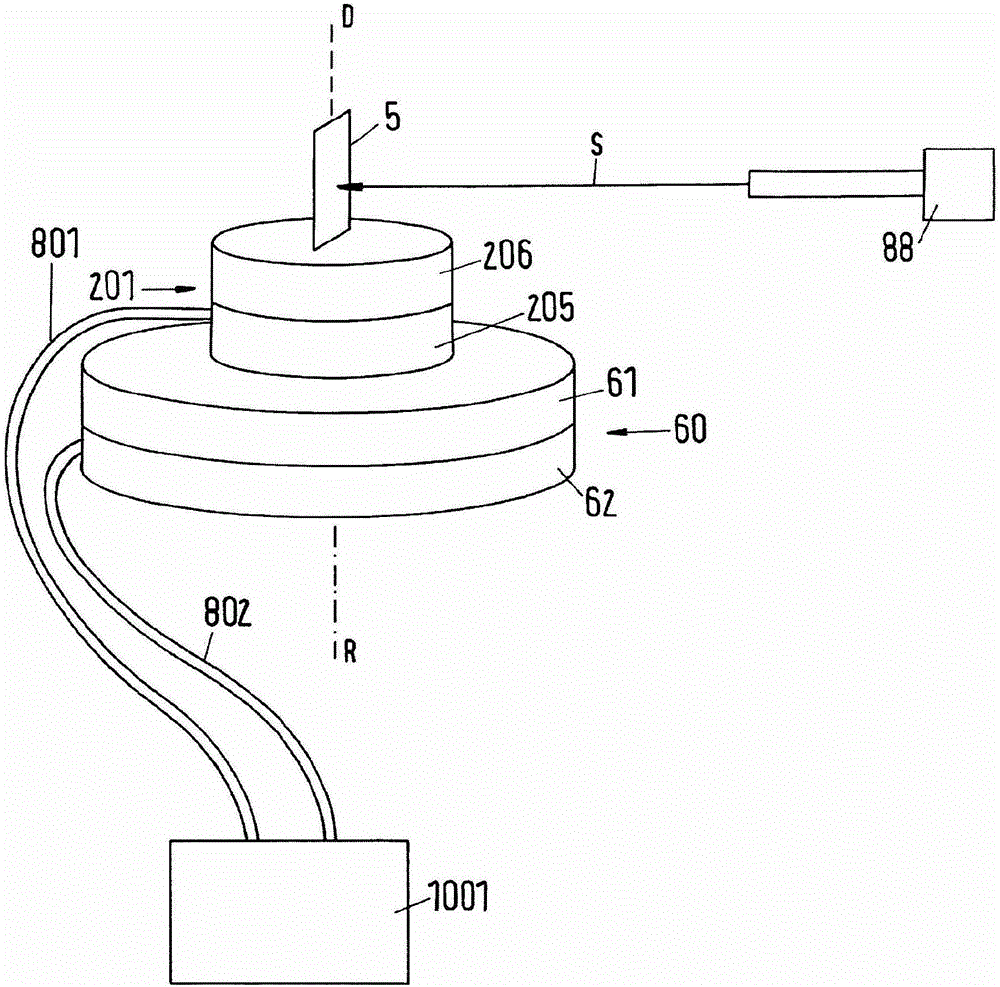

[0467] exist figure 1 A possible configuration for the error detection process is shown in : a rotary device 201 is mounted on a reference rotary device 60 , here a rotary table with a lower part 62 and a rotary disk 61 . The rotary device 201 is in this example also a rotary table in which a rotary angle measurement system (not shown) is to determine a rotary angle error. The turntable 201 has a lower part 205 and a turntable 206 . The lower part 205 of the rotary table 201 rests on the rotary disk 61 of the reference rotary device 60 . Due to the friction between the disk 61 and the lower member 205 and the own weight of the rotating disk 201 , the lower member 205 is connected to the rotating disk 61 without relative rotation. The disc 61 of the reference turntable 60 is rotatable relative to the lower part 62 about the axis R of the reference turntable. The disc 206 of the turntable 201 is rotatable about the axis D relative to the lower part 205 . Axes D and R are ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com