Working platform fixing system of curtain wall window cleaning machine

A fixing system and technology of window cleaning machine, which is applied in the direction of window cleaning, cleaning equipment, household appliances, etc., can solve the problems of unable to meet the requirements, the gondola cannot be close to the curtain wall, and the gondola and the curtain wall cannot keep a certain distance, etc. To achieve the effect of reasonable structure design, wide application range, convenient disassembly and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below through specific examples, but it is not intended to limit the implementation scope of the present invention.

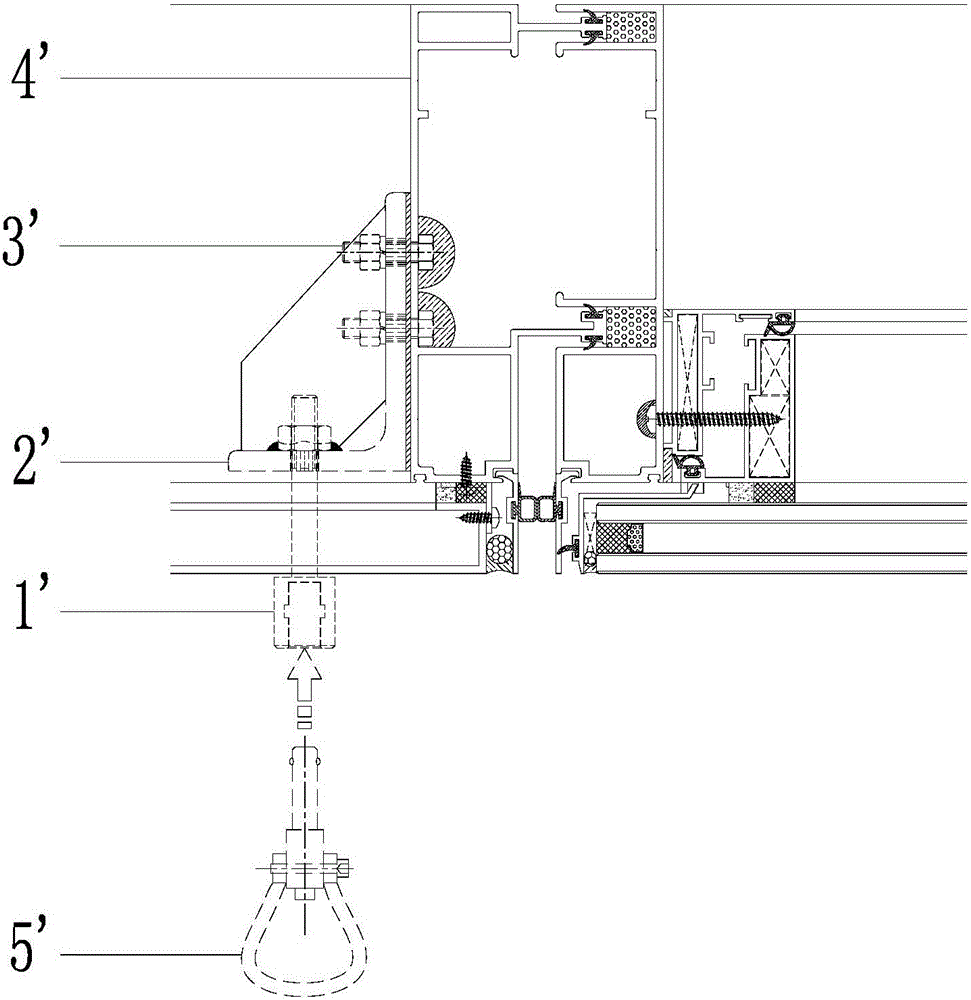

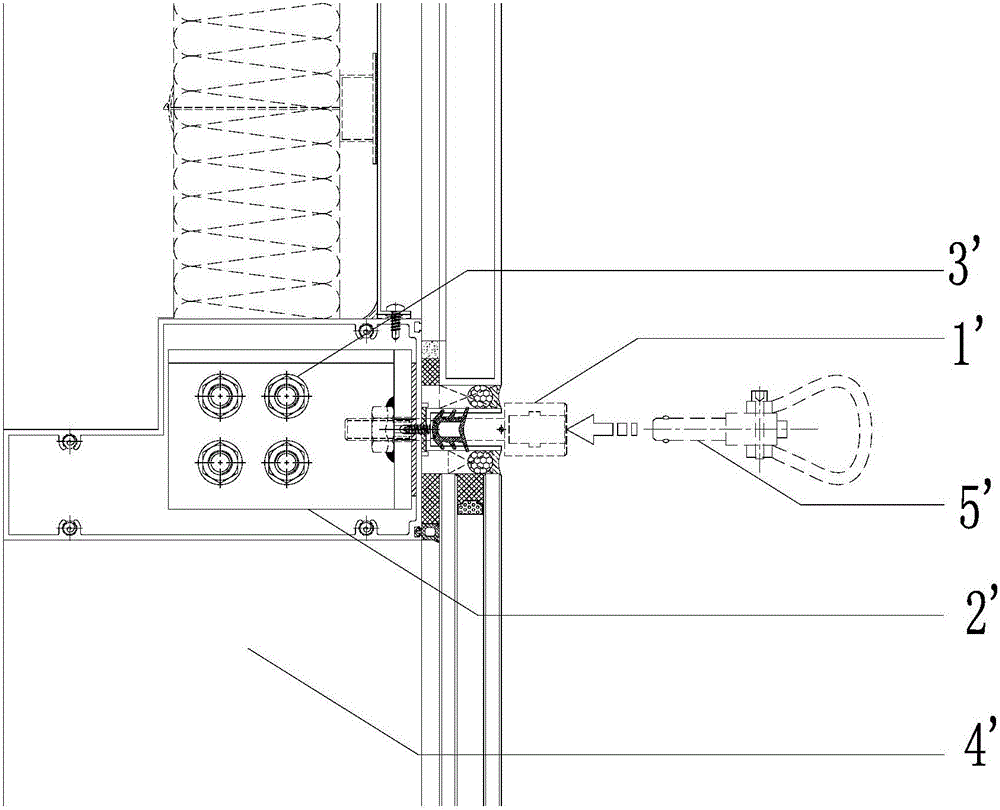

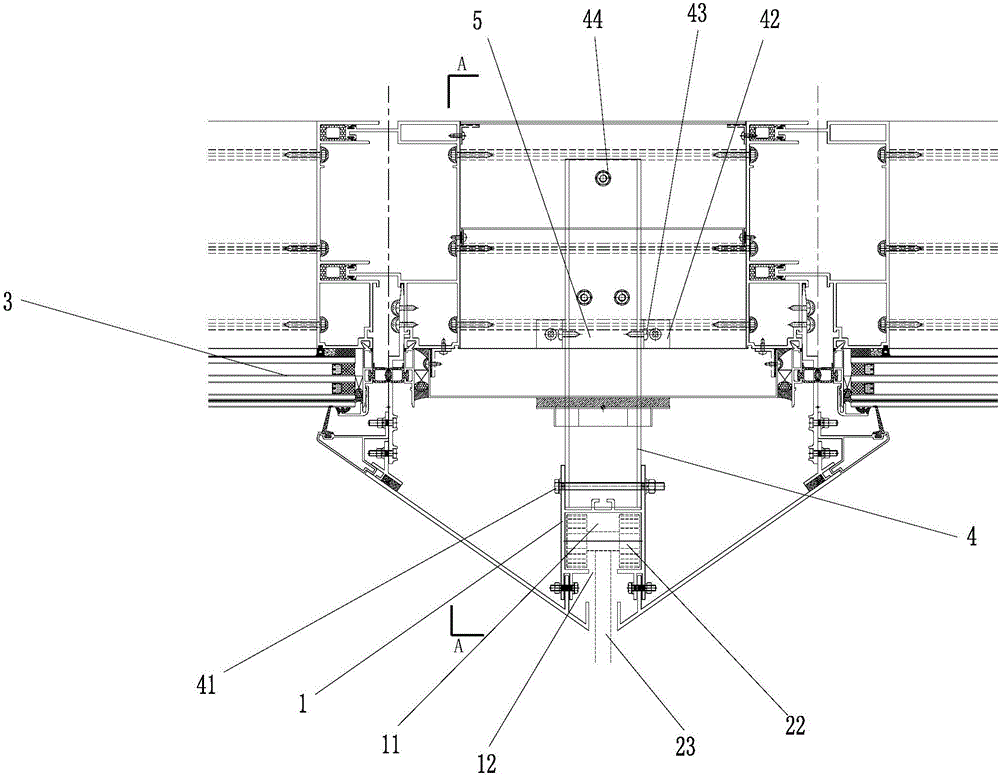

[0021] Such as image 3 , Figure 4 , Figure 6 , Figure 7 As shown, the present invention provides a curtain wall window cleaning machine gondola fixing system, which includes adjacent mullion guide rails 1 and mullion guide devices 2 corresponding to each mullion guide rail 1 .

[0022] The mullion guide rail 1 is located on the outer side of the curtain wall panel 3, and is connected with several vertically distributed U-shaped connectors 4 through bolts 41. 5 connections. The angle aluminum 42 and the screw 43 can limit the displacement of the U-shaped connector 4 parallel to the direction of the curtain wall, and the bolts 44 can limit the displacement of the U-shaped connector 4 in the vertical direction and the direction perpendicular to the curtain wall. A vertical guide rail groove 11 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com