A silicone strip fixed-length cutting machine

A technology of silica gel strips and cutting machines, which is applied in metal processing and other directions, can solve the problems of low cutting quality and low cutting efficiency of silica gel strips, and achieve the effects of improving production efficiency, saving manpower, and superior product processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention provides a silicone strip cut-to-length cutting machine. In order to make the purpose, technical solution and effect of the present invention more clear and definite, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

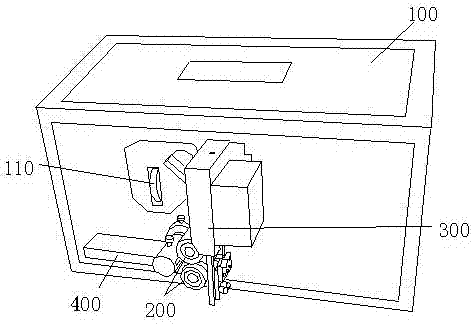

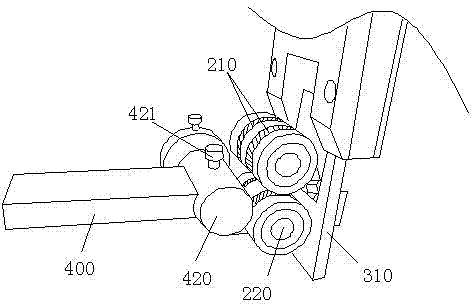

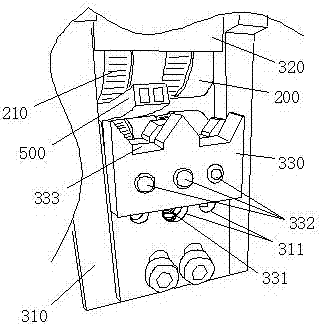

[0021] Such as figure 1 and image 3 A fixed-length cutting machine for silica gel strips shown, which includes a control box 100, a silica gel strip conveying wheel 200 for driving the silica gel strip 500 to move, and a cutter for cutting the silica gel strip after the silica gel strip conveying wheel 200 Mechanism 300, the silicone strip conveying wheel and the cutter mechanism are respectively controlled by the control box, under the control of the control box, the silica gel strip 500 is input from one end of the silica gel strip conveying wheel, and enters the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com