Method for soft measurement of iron ore sintering process state

A sintering process and soft measurement technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of lack of theoretical basis and universality in the value of set temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and examples.

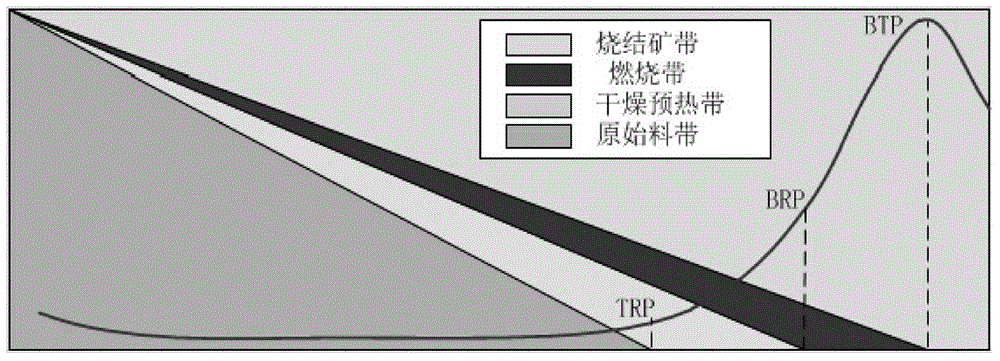

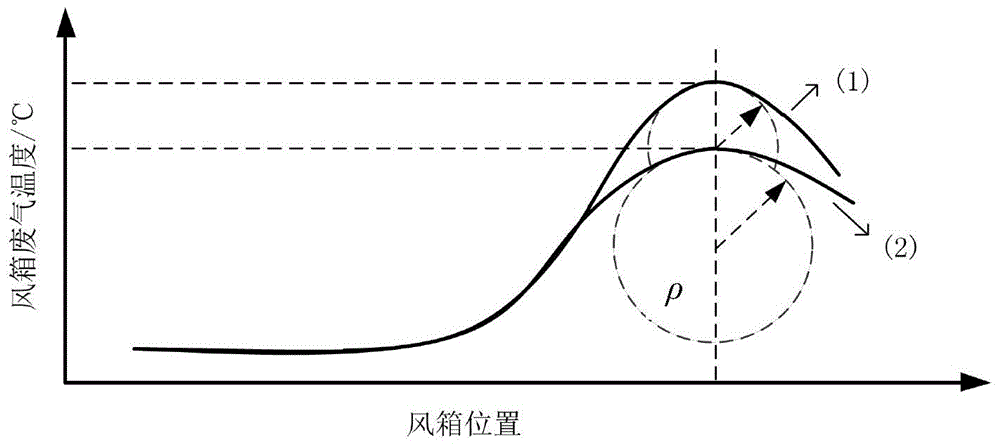

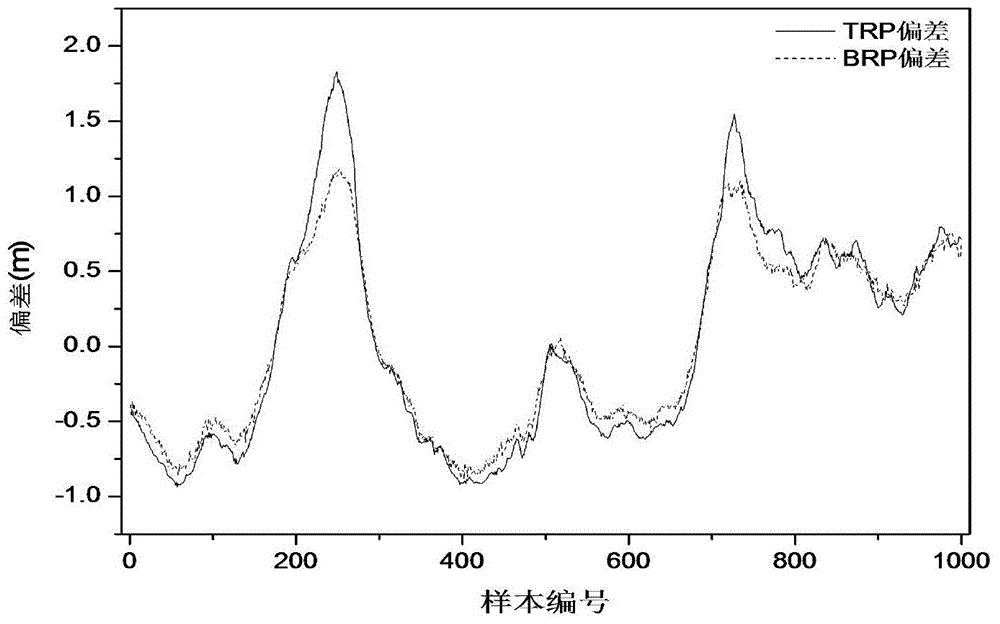

[0036] In this embodiment, the soft measurement method for the state of the iron ore sintering process is based on the temperature division standards and moving characteristics of each zone (drying zone, combustion zone, and sintering zone) of the iron ore sintering material layer, based on the exhaust gas temperature detected online, using The segmental fitting method calculates the position of exhaust gas temperature rise point (TRP), inflection point (BRP) and sintering end point (BTP) (such as figure 1 ), and divide the state interval according to the statistical characteristics of each parameter to characterize the state of the sintering process. μ represents the mean value of the process state parameters in a certain period of time, σ represents the standard deviation, and the state is divided as follows:

[0037] Table 1 Division of process states...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap