Feeding device for mature vinegar fumigation pool

The technology of a feeding device and a fermented grain pond is applied in the field of a feeding device for a mature vinegar fumigation pond, which can solve the problems of high cost, long distance, complicated installation structure and the like, and achieve the effects of simple structure and convenient process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

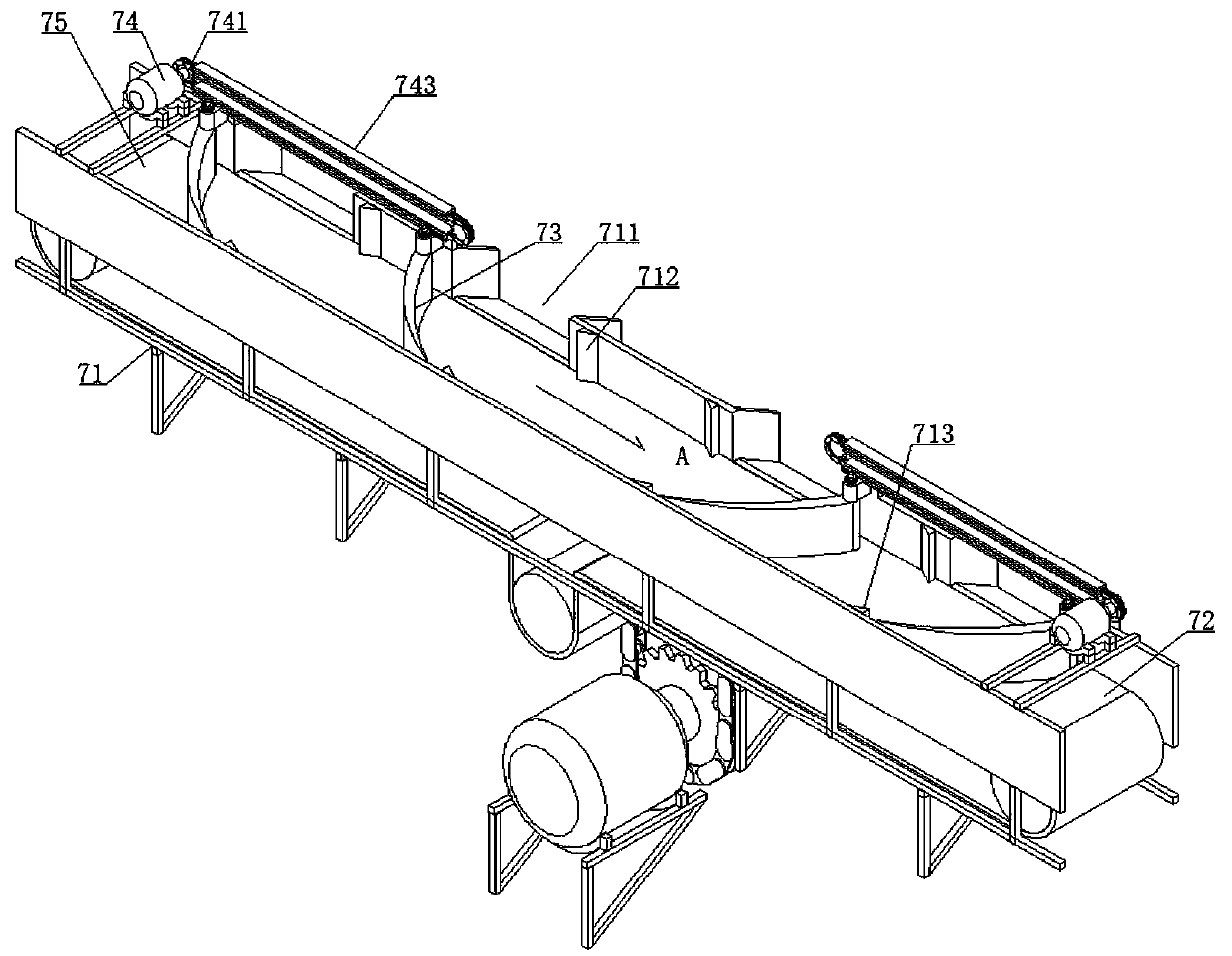

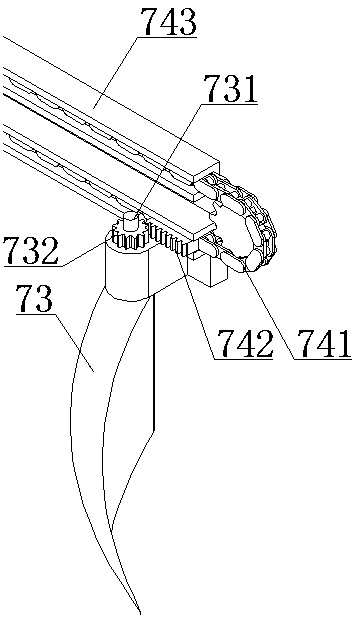

[0013] An old vinegar fumigation pool charging device, comprising a mounting frame 71 installed on the wall, a belt conveyor 75 fixed on the mounting frame, and a conveyor belt 72 matching the belt conveyor. There are baffles on both sides of the conveyor belt. A discharge port 711 is opened on the side baffle, a discharge baffle 73 is hinged at the discharge port, a discharge port guide step 712 is provided in the incoming direction of the discharge port, and a plate guide step 713 is provided opposite to the discharge port. The plate is hinged to the inside of the conveyor through a rotating shaft 731, and an opening and closing gear 732 is fixed on the rotating shaft 731. An opening and closing motor 74 and an opening and closing chain 741 driven by the opening and closing motor are installed on the conveying frame. A supporting chain rail 743 is provided on the horizontal part of the opening and closing chain. The opening and closing chain and the discharge baffle are opened...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com