Installing structure for idler wheel

A technology of installation structure and idler gear, which is applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problem of low versatility of the engine cylinder, achieve flexible adjustment, increase the generalization rate, and improve the axial precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

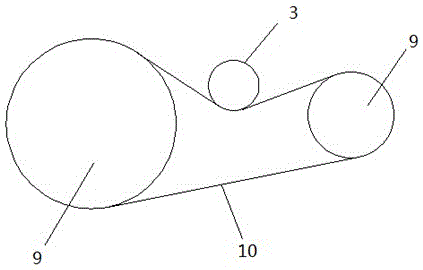

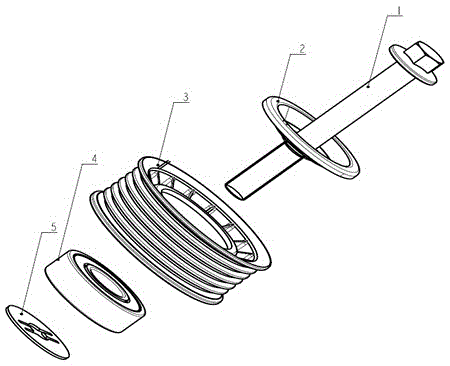

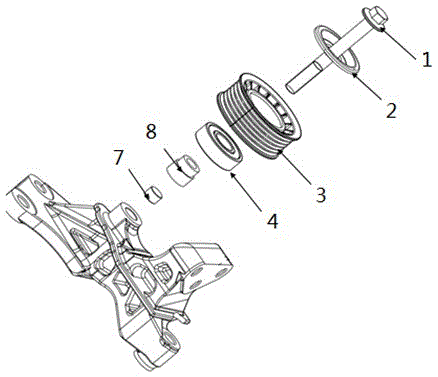

[0020] A kind of idler installation structure described in the present invention is mainly used in engine front-end gear train, such as figure 1 , Figure 4 to Figure 7 As shown, it includes: the idler 3 leading to the belt 10 of the front end gear train 9 of the engine, the bearing outer ring 42 sleeved tightly in the bearing 4 in the installation shaft hole of the idler, the installation formed on the engine block and adjacent to the idler The platform 6 passes through the inner ring 41 of the bearing in turn, extends into the bolt hole 61 opened on the installation platform and fastens the bolt 1 with the installation platform, and sets a stepped cylinder 8 axially between the installation platform 6 and the bearing 4, and the step The cylinder is limited by the cooperation of the big end and the small end to form a stepped structure 81. The stepped cylinder 8 is coaxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com