Water tank module capable of selecting water channels and washing machines with module

A water channel and water tank technology is applied in the field of washing machine water tank modules, which can solve the problems of low degree of generalization of components and high cost, and achieve the effects of improving the generalization rate of components, improving production efficiency, and improving the generalization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

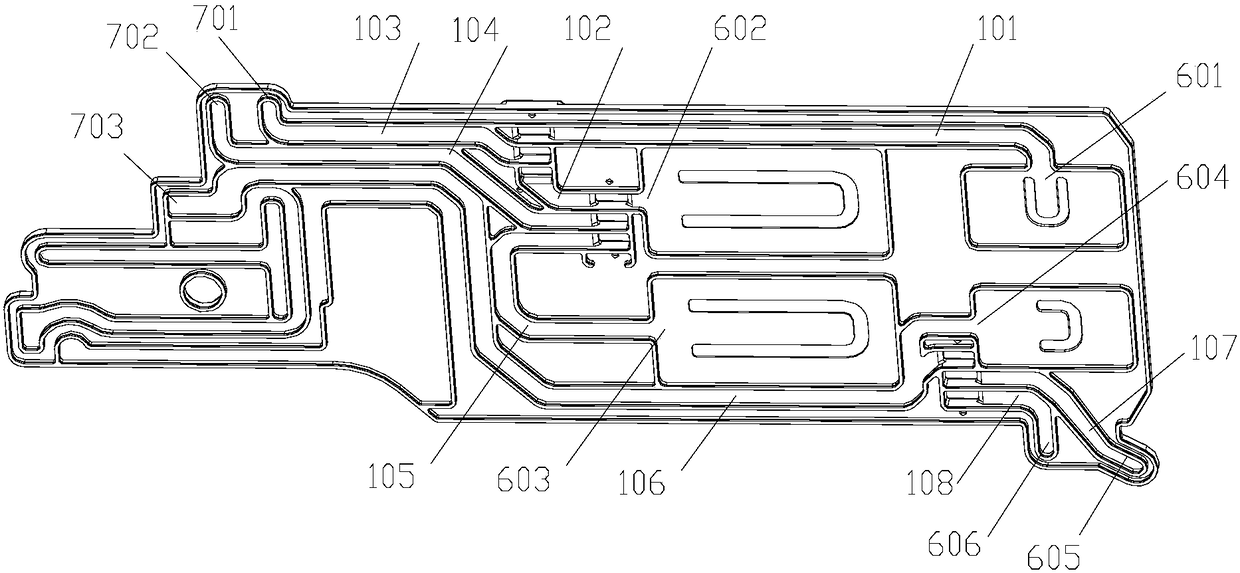

[0067] Such as figure 1 , figure 2 As shown, this embodiment provides a water tank module with selectable water channels, including a water channel board, a plurality of water channels are arranged on the water channel board, and a water channel clip is provided on at least one of the water channels, and the water channel is blocked by the water channel clip or selected to conduct different waterway.

[0068] Further, bayonets are provided on the waterway plate, and the bayonets are opened on different waterways, and the waterway fasteners are fixed on the bayonets to block and / or conduct different waterways, so as to select the waterway that realizes the corresponding function. Blocking / conducting of water inlet channels.

[0069] Further, a plurality of water outlet ports respectively corresponding to respective water channels are provided on the water circuit board, and the water outlet ports include a first water outlet port 601 and a second water outlet port 602;

[0...

Embodiment 2

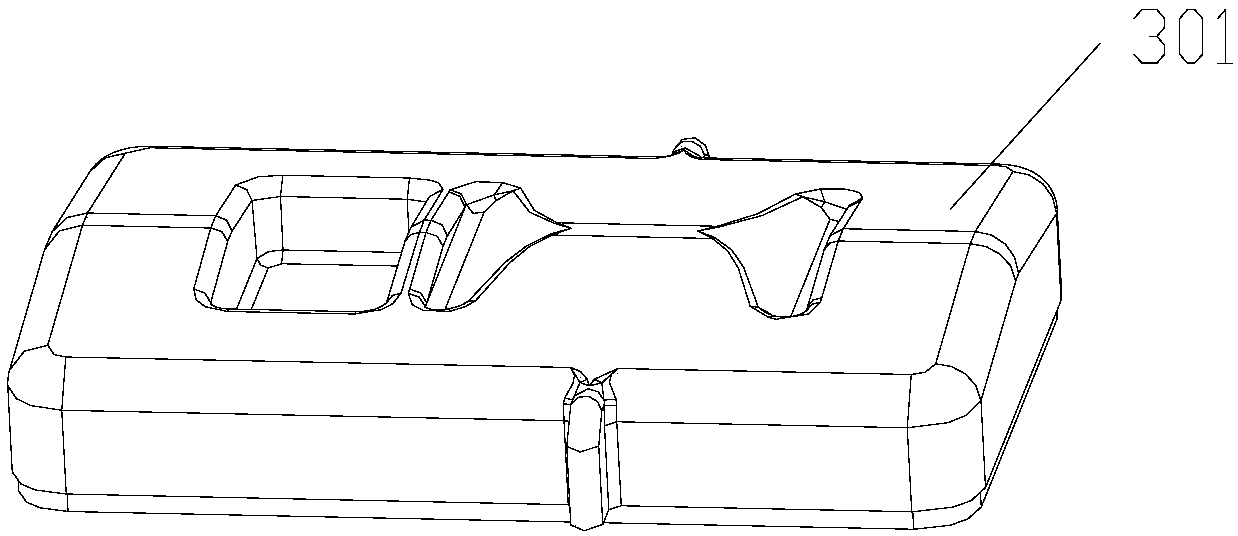

[0091] Such as Figure 3-6 As shown, this embodiment provides one or more waterway clips, the waterway clips are clips, the clips are installed on the bayonet of the waterway board, and the clips include The protruding part 802 for blocking the water channel and / or the inner concave part 801 for connecting at least two water channels.

[0092] The clamping member includes an open box body, and the protruding part 802 and the inner concave part 801 are arranged in the box body;

[0093] The waterway clip includes a double-way clip, and the double-way clip includes a protruding part 802 that blocks one waterway and an inner concave part 801 that simultaneously communicates with two waterways;

[0094] The waterway clip includes a three-way clip, and the three-way clip includes an inner recess 801 that communicates with three waterways at the same time;

[0095] Preferably, the first water channel clip 301 is a two-way clip, the protruding portion 802 blocks the connection betw...

Embodiment 3

[0111] This example provides Figure 11 A sink module as shown, also includes Figure 9 The supporting frame 501 shown is the water tank module described in the first embodiment and the water channel clip described in the second embodiment.

[0112] There are three bayonets on the waterway plate;

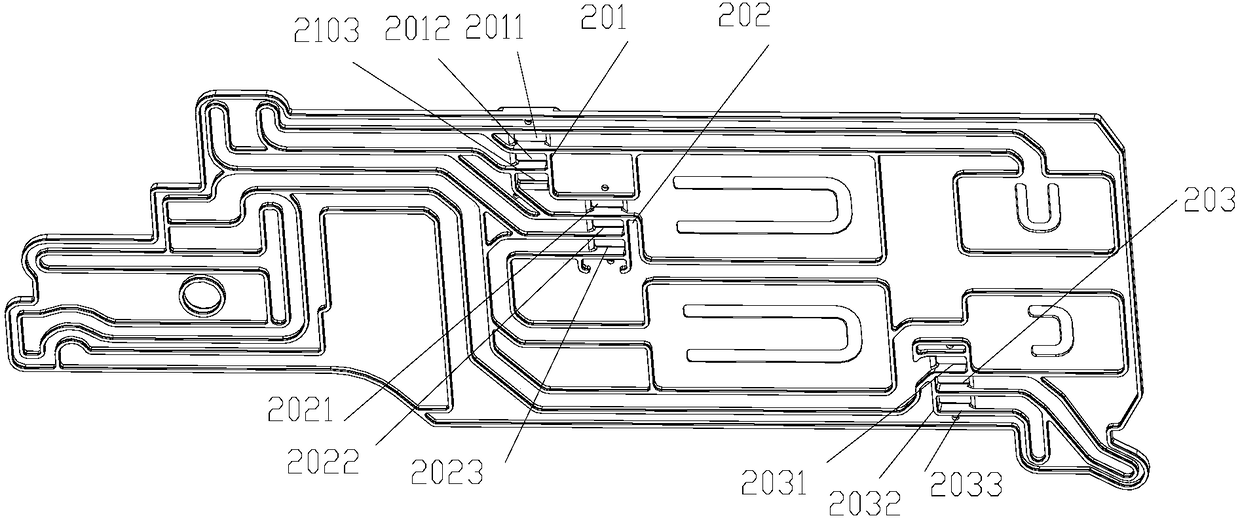

[0113] Further, the first bayonet 201, the second bayonet 202 and the third bayonet 203 respectively include a first water outlet, a second water outlet and a third water outlet, and one of the three water outlets is The water outlet is connected with the water channel connected with the water inlet, such as figure 2 shown.

[0114] Further, the first bayonet 201 passes through the first water outlet of the first bayonet 201, the second water outlet and the third water outlet pass through the first water channel 101, the second water channel 102 and the third water channel 103, specifically:

[0115] The connection between the first bayonet port 201 and the first water channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com