Heat source composition for heating non-burning tobacco products and its application

A tobacco product, non-combustion type technology, applied in the field of heat source compositions for non-combustion tobacco products, can solve the problems of few technical reports and short development time, and achieve the effects of high heat generation efficiency, long duration and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] The design test of embodiment 1 composition formula

[0074] 1. Orthogonal test verification

[0075] The present invention determines that the consumption of the main components aluminum powder and / or iron powder and / or magnesium powder, potassium permanganate, manganese dioxide, tartaric acid and potassium hydrogen tartrate, anhydrous magnesium sulfate, activated carbon participating in the reaction is the main influencing factor. EXAMPLES Five levels are selected for each factor, and the six-factor five-level L25 (56) orthogonal test design scheme is used for experimental verification. To avoid redundant description, this embodiment provides the orthogonal test data of aluminum powder as an example for illustration.

[0076] According to the orthogonal test design, determine reasonable influencing factors and level dosage, because aluminum powder or magnesium powder, potassium permanganate and acidic substances are necessary substances for the reaction, while mangan...

Embodiment 2

[0121] The detection of embodiment 2 overall reaction rate

[0122] According to the known reaction principle, combined with the addition amount of each reactant in the reaction, the theoretical value of manganese content in the obtained sample can be calculated. The sampling positions are divided into the whole reaction product, the inner and outer layers of the product, the upper layer of the product (the end closer to the heating tube cover), the middle layer and the lower layer (the end farther away from the heating tube cover), and the weighed mixed solid generates heat. The material mass is m 0 .

[0123] Knowing the proportion of potassium permanganate added, it can be known that the mass of potassium permanganate in the mixed solid material is m 1 , the mass of added aluminum powder, iron powder or magnesium powder is m 2 , the amount of substances of potassium permanganate and metal reactant can be calculated as n 1 and n2 , where n 1 =m 2 / M KMnO4 , n 2 =m m...

Embodiment 3 3

[0157] Embodiment 3 three kinds of metal mixed application tests

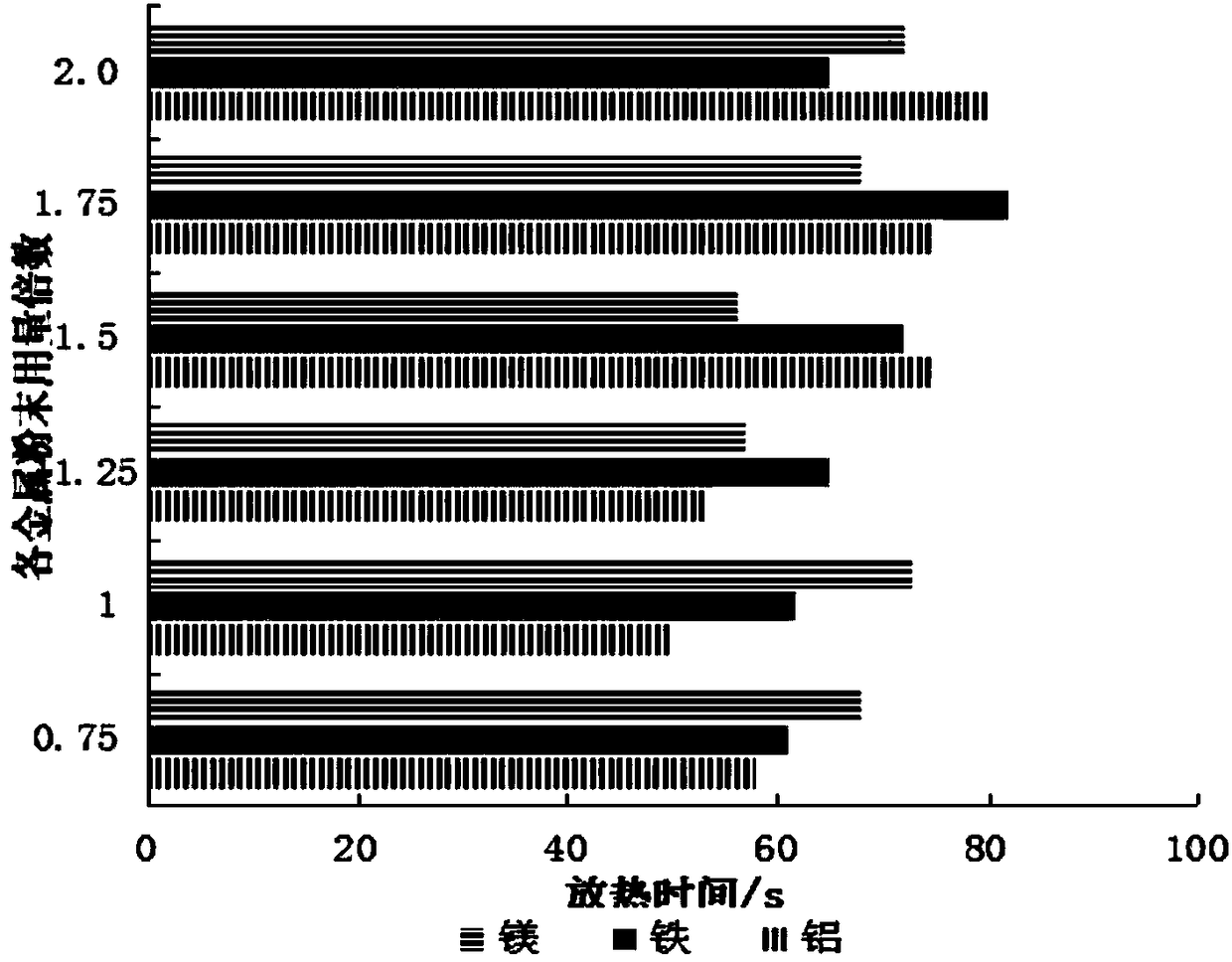

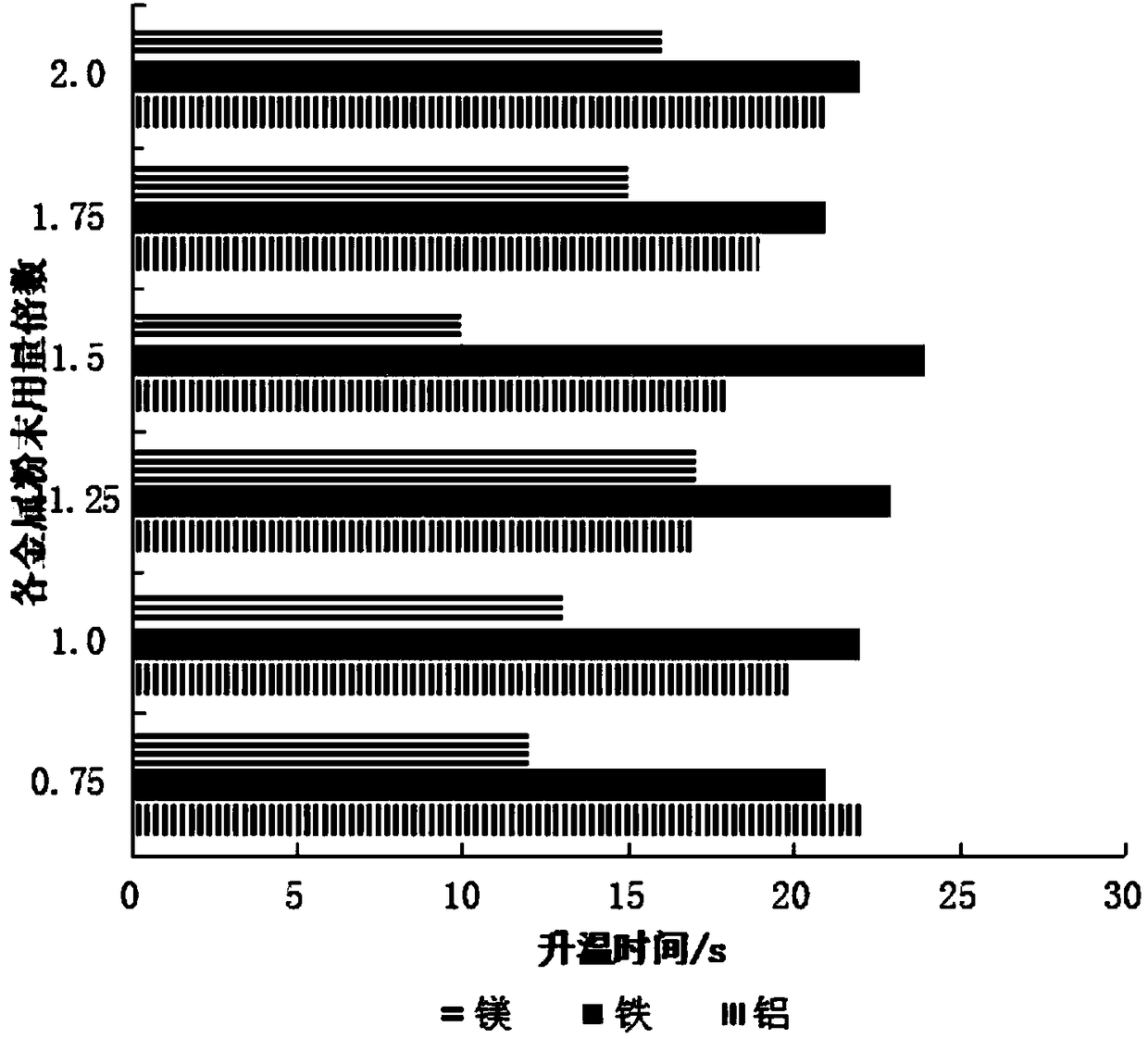

[0158] Based on the above test results, this embodiment further compares the maximum reaction temperature, exothermic time and heating time of aluminum, iron and magnesium as metal reactants respectively. The maximum reaction temperature, exothermic time and heating time of the three reactions are as follows: Figures 45 to 47 shown.

[0159] analyze Figure 45 to Figure 47 In the situation shown, in order to achieve rapid temperature rise, magnesium is the most suitable for single application, and the selection range is 0.75 to 1.5 times of magnesium; at the same time, from the trend, choosing 0.5 times of magnesium may also achieve the effect of rapid temperature rise. And in conjunction with the results of Table 11, the reaction rate of the lower layer that initially contacts water is the highest (88.17%, higher than 75.52% of the middle layer and 77.22% of the lower layer), and far higher than that of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com