bone cement mixing syringe

A syringe and bone cement technology, applied in the field of medical devices, can solve the problems of time-consuming and labor-intensive, affecting the surgical effect, and increasing the risk of contamination of bone cement, so as to shorten the operation time, facilitate the operation, and reduce the risk of contamination. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The bone cement injector includes a premix cylinder, an injection head, a stirring device, and an injection device.

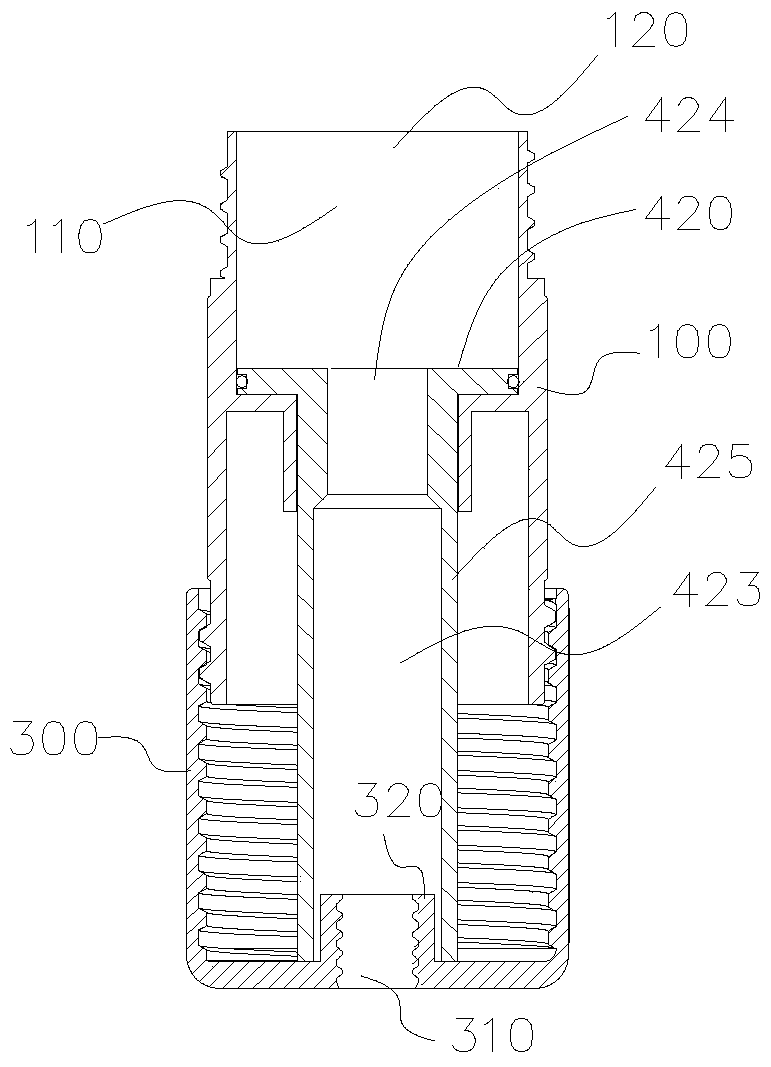

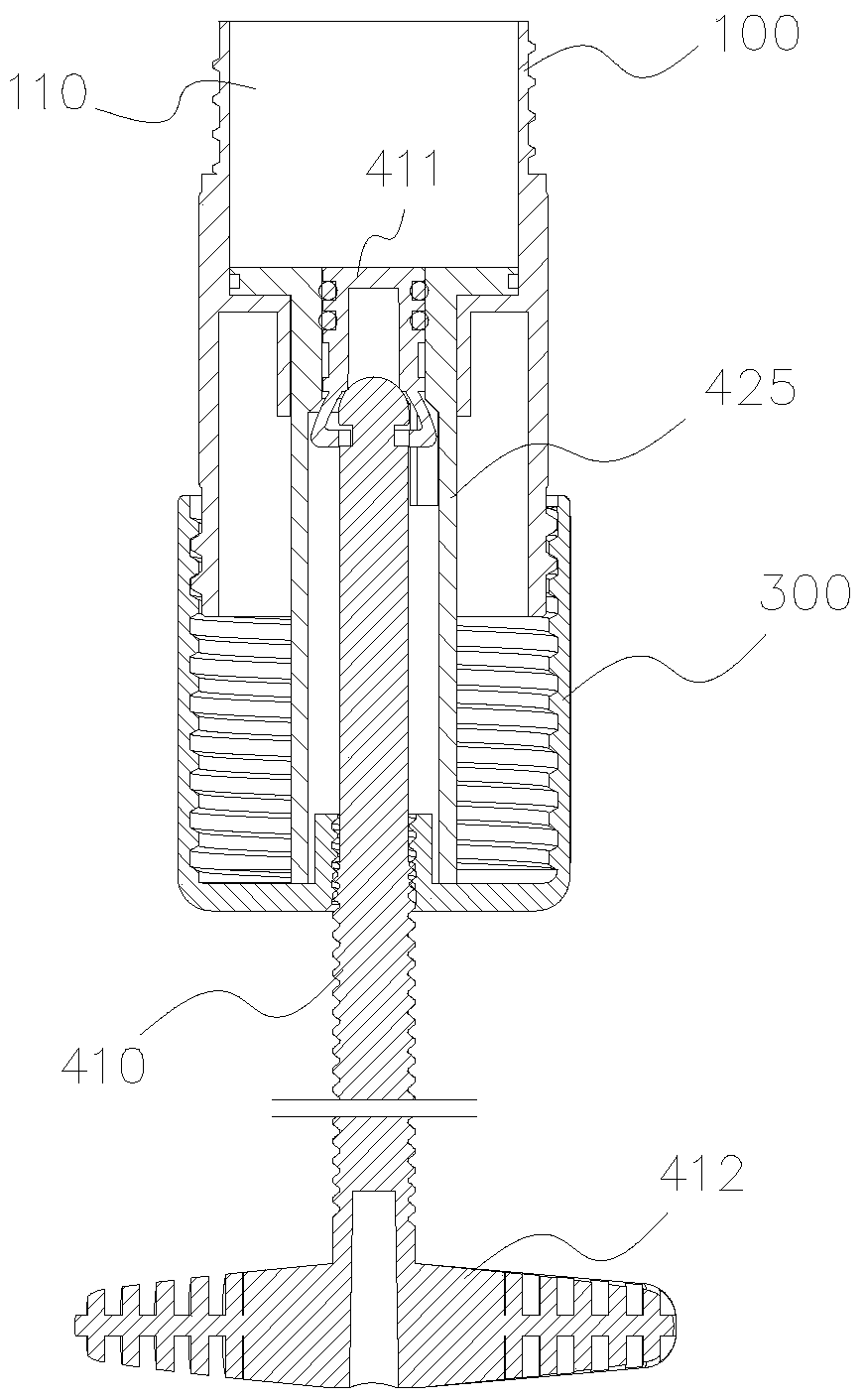

[0041] Such as figure 1 , 2As shown, the premixing cylinder 100 is provided with a premixing chamber 110, the first end of the premixing cylinder 100 is provided with a first opening 120 communicating with the premixing chamber 110, and the second end of the premixing cylinder is provided with a first opening 120 communicating with the premixing chamber 110. Connected limit holes. The injection device includes an injection cover 300 , an injection rod 410 , and an injection cylinder 425 . The injection tube 425 is provided with an injection channel 423 , the first end of the injection tube 425 is provided with an injection plate 420 , and the injection plate 420 is provided with an injection hole 424 which communicates with the injection channel 423 . The first end of the injection rod 410 is provided with an injection head 411 , the second end of the...

Embodiment 2

[0049] The difference between embodiment two and embodiment one is:

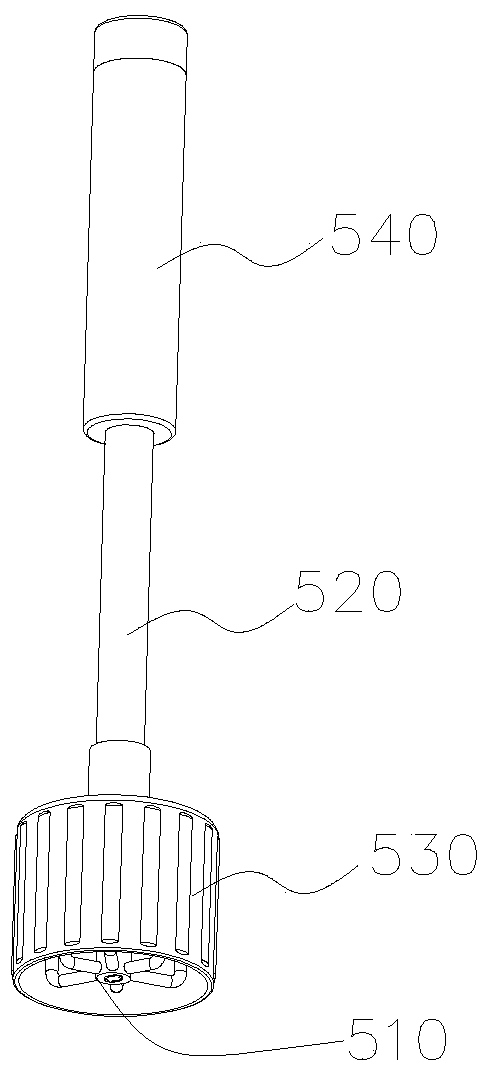

[0050] Such as Figure 10 , 11 As shown, the stirring shaft 520 is provided with a gear 522 , and the stirring cover 530 is also provided with a rack 550 and two rack holes. The rack 550 passes through the two rack holes in turn, and the rack 550 meshes with the gear 522 . When stirring the bone cement, move the rack 550 back and forth in the rack hole, so that the rack 550 drives the gear 522 to rotate, thereby driving the stirring head 510 to rotate for stirring.

Embodiment 3

[0052] The difference between embodiment three and embodiment one is:

[0053] refer to Figures 1 to 9 , there is no limit hole in the premixing cylinder, the second opening communicated with the premixing chamber is provided on the premixing cylinder, the second opening is opposite to the first opening, the injection cap 210 is set at the first opening 122, the second The two openings are compatible with the stirring cap 530 and the injection cap 300, the stirring cap 530 can be set on the second opening, and the injection cap 300 can also be set on the second opening. When in use, first cover the injection cap 210 on the first opening, and set the stirring cap 530 on the second opening. At this time, the stirring head 510 is inserted into the premixing cavity 110, and the bone cement is stirred by using the stirring head 510. After stirring, remove the stirring cover 530, and set the injection cover 300 on the second opening. At this time, the injection plate and the injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com