A servo hydraulic flushing system

A flushing system and hydraulic technology, applied in the field of hydraulic flushing, can solve problems such as unsatisfactory flushing effects, achieve fast response and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

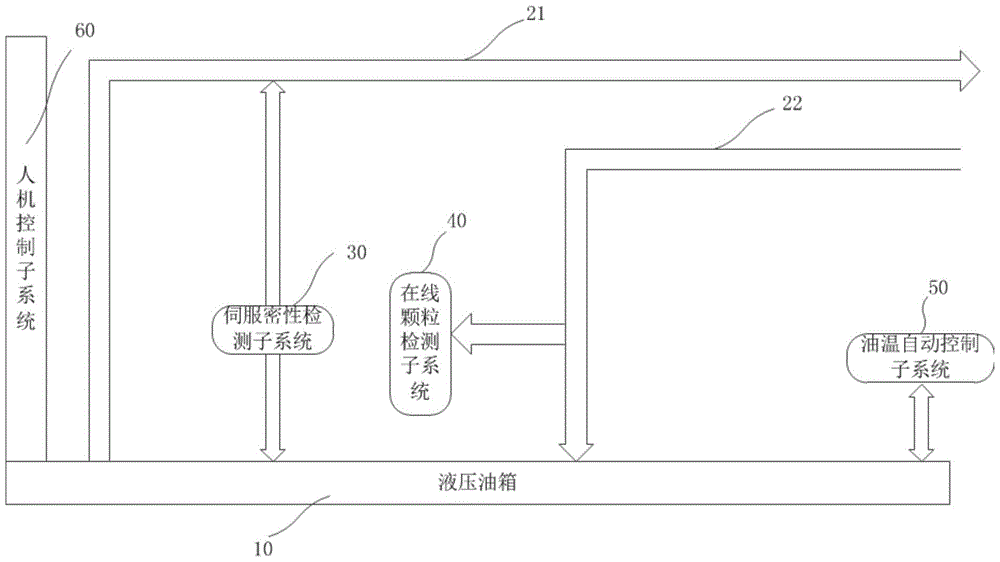

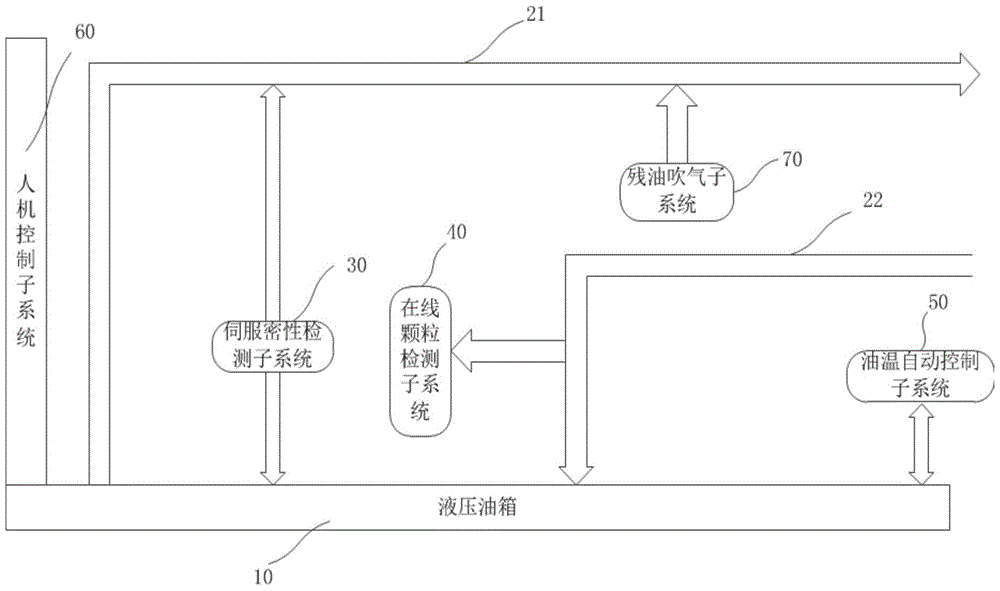

Embodiment 1

[0045] The specific use of the servo hydraulic flushing system provided in Embodiment 1: The servo flushing system can realize one-button operation. Through the intelligent program programming of the man-machine control computer, the parameters are set before flushing, tightness and other operations, and the program is started after one button It will automatically output, monitor, and feed back the work of each control sensor and control element, and make corresponding records and safety monitoring; in the auxiliary human control system (suction / discharge, residual oil blowing), manual operation can be replaced by manual operation, Easy to operate and more environmentally friendly.

[0046] Compared with the ordinary flushing system, the servo hydraulic flushing system provided by the above embodiment cleverly combines and integrates each subsystem, and the overall equipment has one-button intelligent operation, high integration, energy saving and high efficiency, high degree ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com