tape cutter

A tape cutting and tape technology, which is applied in the directions of sending objects, thin material handling, transportation and packaging, etc., can solve the problems of far from silent, incomplete improvement, and no improvement in noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

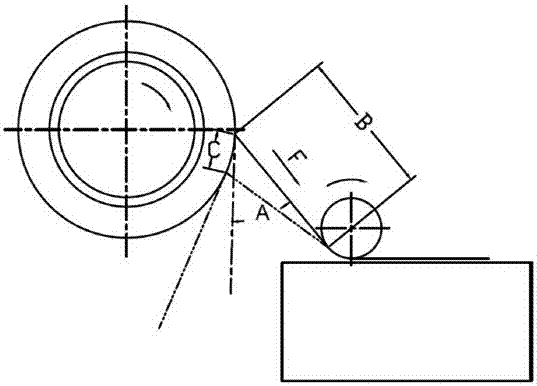

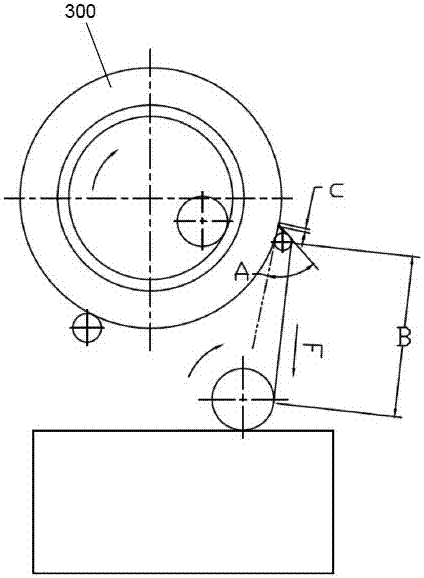

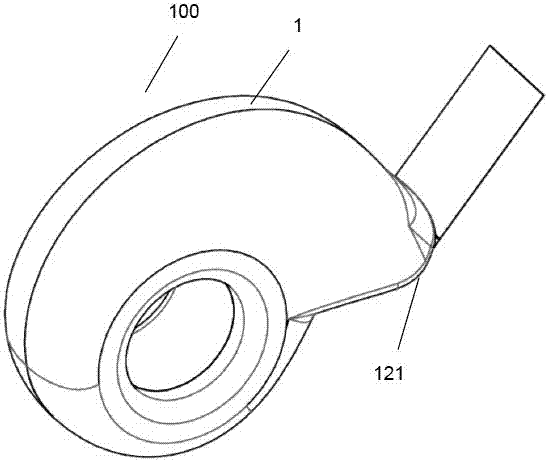

[0032] see Figure 3 to Figure 5 , the tape cutter 100 of the present invention is used to install and cut the tape roll 200 . The tape cutter 100 includes a housing 1 and its internal structure. The casing 1 includes a main casing 10 and a secondary casing 20 buckled with the main casing 10 . The main housing 10 and the auxiliary housing 20 include a substantially circular main body 11 and a side 12 extending from the main body 11 to one side. An outlet 121 is formed at an outermost end of the side 12 . A tape roll sleeve 3 for covering the tape roll 200 protrudes from the middle of the main body side 11 of the main housing 10 . The tape cutter 100 also includes a sound-absorbing roller 5 , a driving wheel 6 , and a rolling wheel 7 near the exit 121 , which are arranged in the main housing 10 and located on one side of the tape roll sleeve 3 . see Figure 4 As shown, it may be possible to define the sticky side of the adhesive tape as the front side, and the other side wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com