Rebar spacing fine-tuning card controller

A technology of steel bar spacing and card controller, which is applied in the direction of mechanical clearance measurement, construction, building construction, etc., can solve the problems of inaccurate control of steel bar spacing, increase construction manpower and time consumption, and reduce production efficiency, etc., to ensure Reinforced concrete quality, reinforced concrete quality assurance, effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

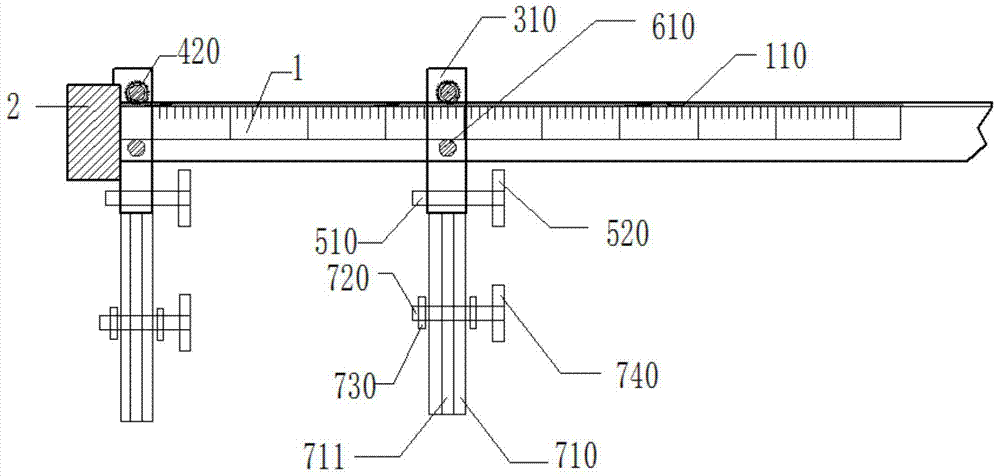

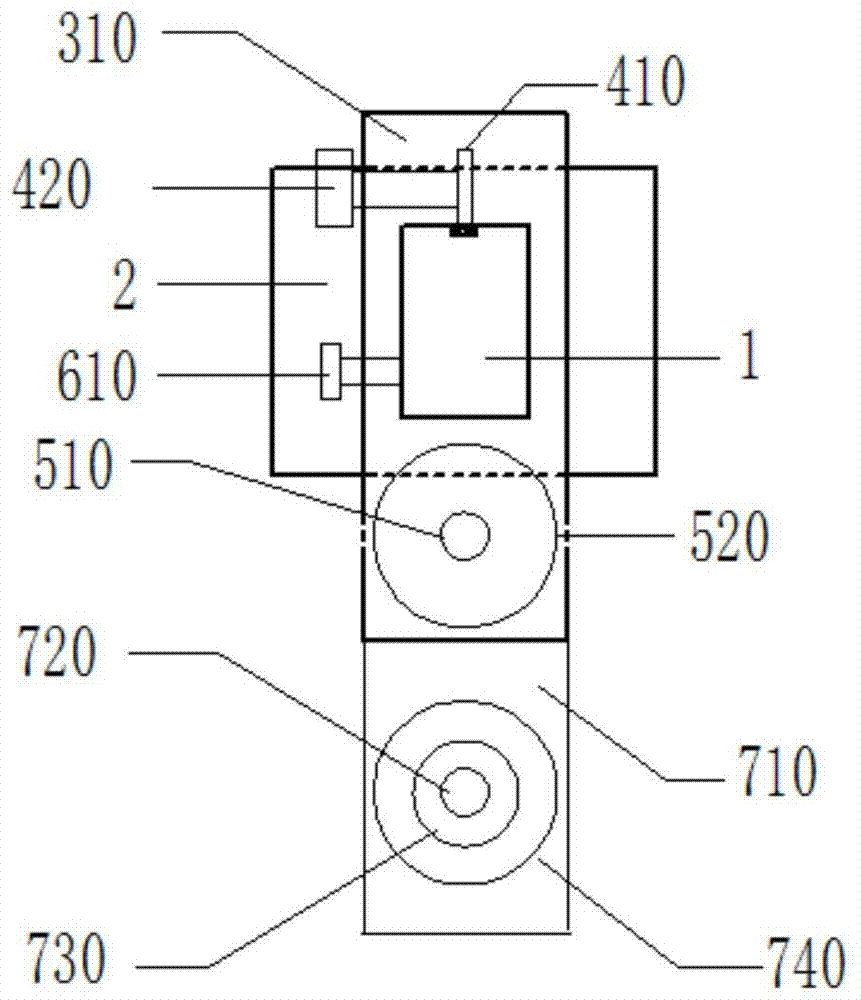

[0032] Such as Figure 1~2 as shown,

[0033] A fine-tuning card controller for steel bar spacing, comprising:

[0034] scale1;

[0035] Baffle 2, which is fixedly arranged at any one of the left and right ends of the scale 1;

[0036] A plurality of card controllers, for any one of the card controllers, it includes:

[0037] A first plate body 310 with a cavity structure, which is vertically sleeved outside the scale 1 through the cavity structure, and can move along the length direction of the scale 1;

[0038] a feeding structure, which is arranged on the first plate 310 and moves the first plate 310 left and right along the scale 1;

[0039] The fastening structure includes a first blocking piece 520 arranged on one side of the first plate body 310 through a connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com