Vibration isolator

A technology of anti-vibration device and inner cylinder, which is applied in the direction of power plant, jet propulsion device, internal combustion propulsion device, etc., can solve the problem of low rigidity and achieve the effect of increasing the stop function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the anti-vibration device of the present invention are illustrated and described below with reference to the drawings.

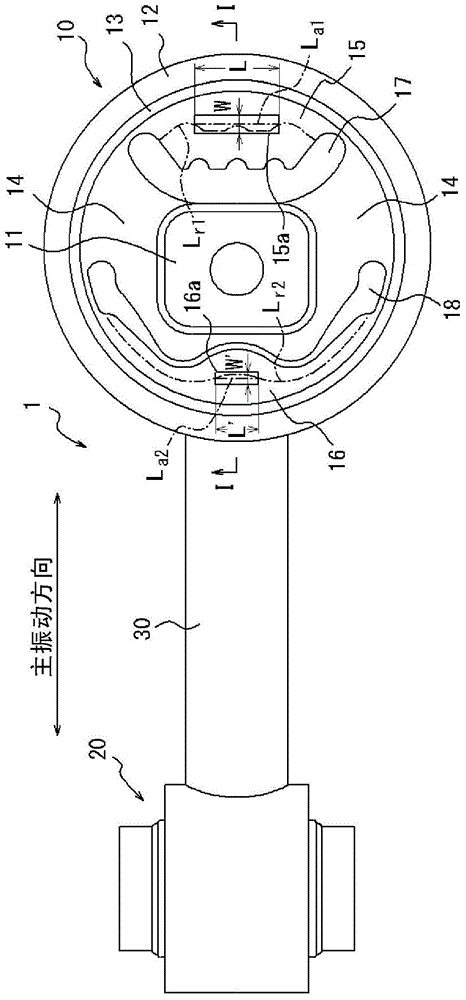

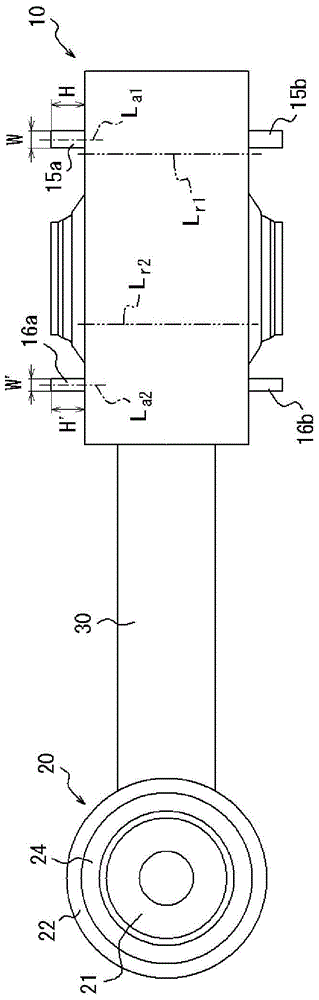

[0021] figure 1 with figure 2 The anti-vibration device 1 in the illustrated embodiment is a torsion bar, which includes a first elastic sleeve 10; a second elastic sleeve 20 whose diameter is smaller than that of the first elastic sleeve 10; and The connecting rod 30 connects the first elastic sleeve 10 and the second elastic sleeve 20 .

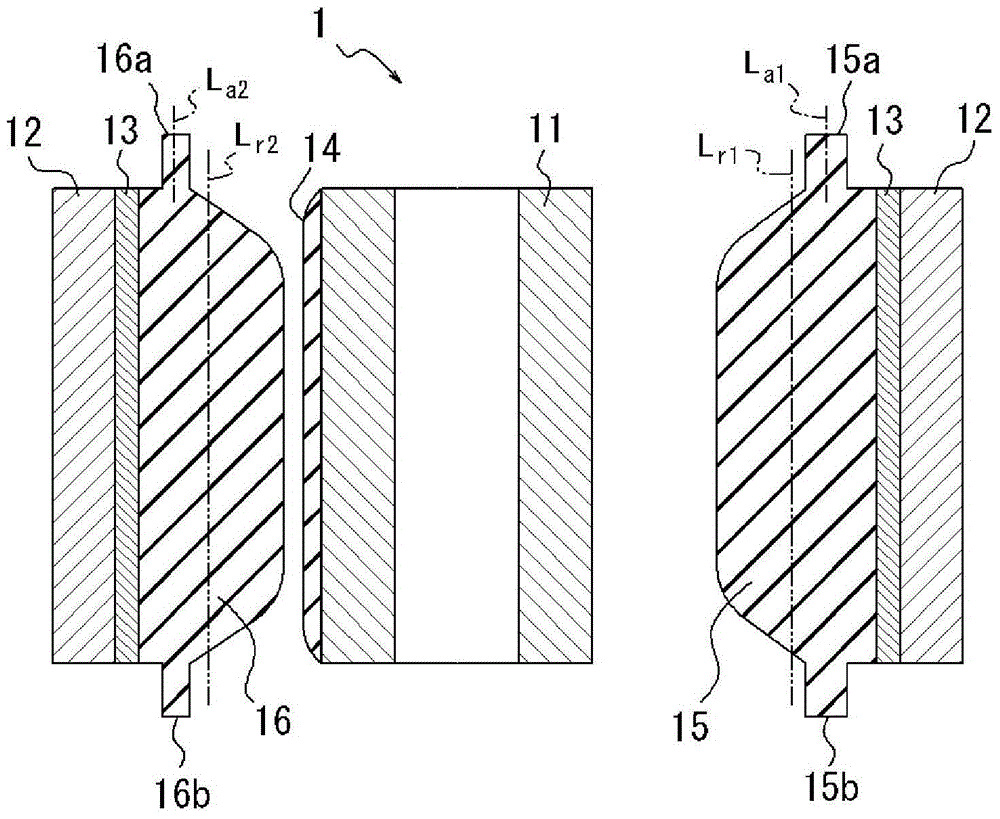

[0022] Such as figure 1 As shown, the first elastic sleeve 10 includes: an inner cylinder 11; a middle cylinder 13; a main body elastic body 14, which connects the inner cylinder 11 and the middle cylinder 13; a stopper elastic body (stopperelasticbody) 15, a stopper elastic body 15 is fixed on the middle cylinder 13 and in the axial direction with the inner cylinder 11 (with figure 1 The direction perpendicular to the surface of the paper, hereinafter also referred to as "inner cylinder axial d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com