Monitoring of condensate drains

A technology of condensate and excretor, which is applied to steam/steam condensers, instruments, steam traps, etc., and can solve the problems of not being able to get the working status and not being able to accurately determine it

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

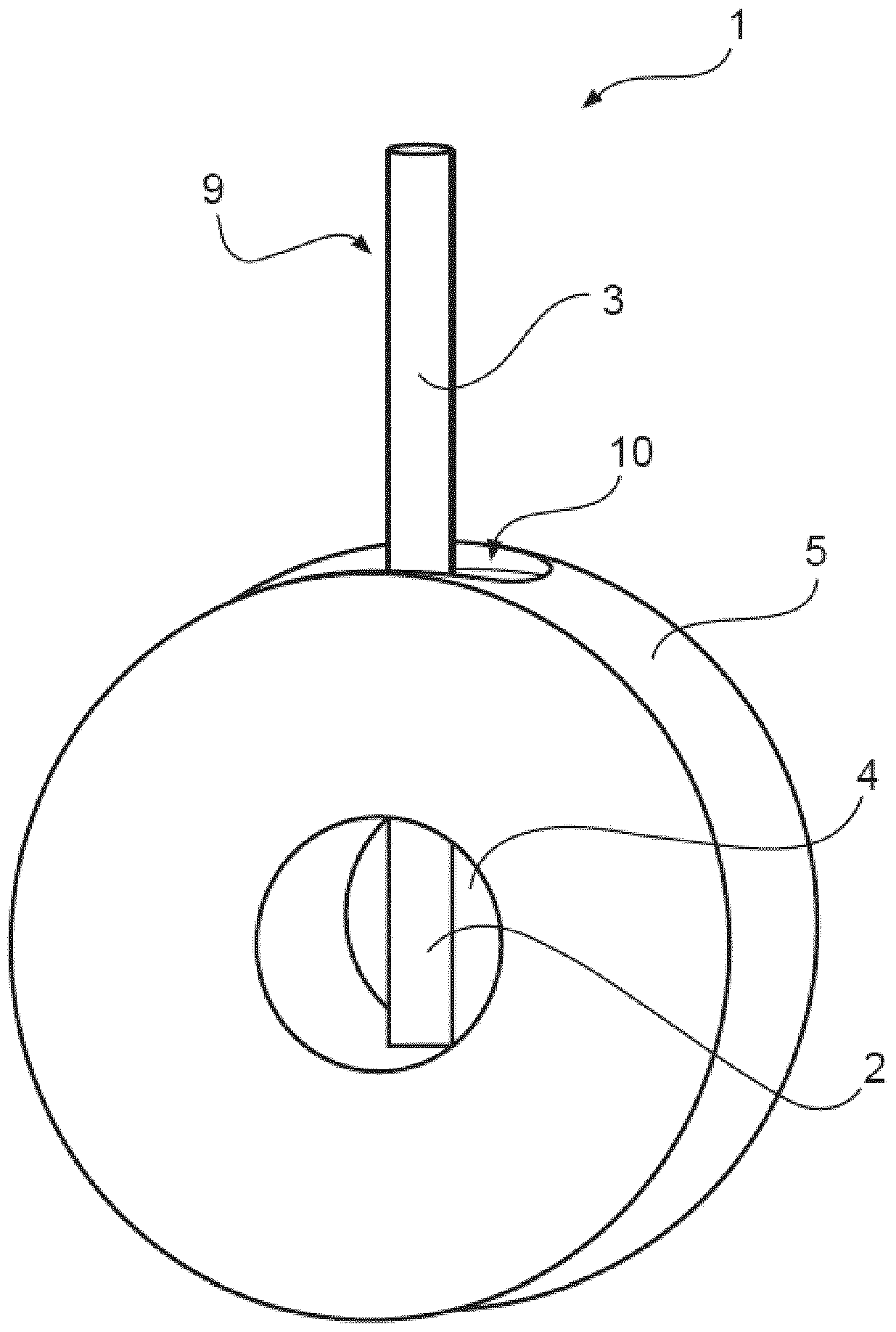

[0059] figure 1 Shown is flow sensor 1 with vibrating body 9 and base body 5 , which is designed in the form of a ring. The vibrating body 9 is designed here in the form of a rod and has a first region 2 and a second region 3 . An opening 10 is provided in the base body 5 , in which opening the vibrating body 9 is arranged. The basic body 5 has an opening 4 with a predetermined flow cross section. The first region 2 of the vibrating body 9 protrudes into the opening 4. Alternatively, the vibrating body 9 can be designed such that the first region adjoins the flow cross section for the medium, ie is arranged adjacent to the flow cross section and thus at least partially contacts the flow surface. A medium, such as a multiphase flow, such as steam and condensate, flows through the predetermined cross section 4 . The second region 3 protrudes from the base body 5 above the opening 10 .

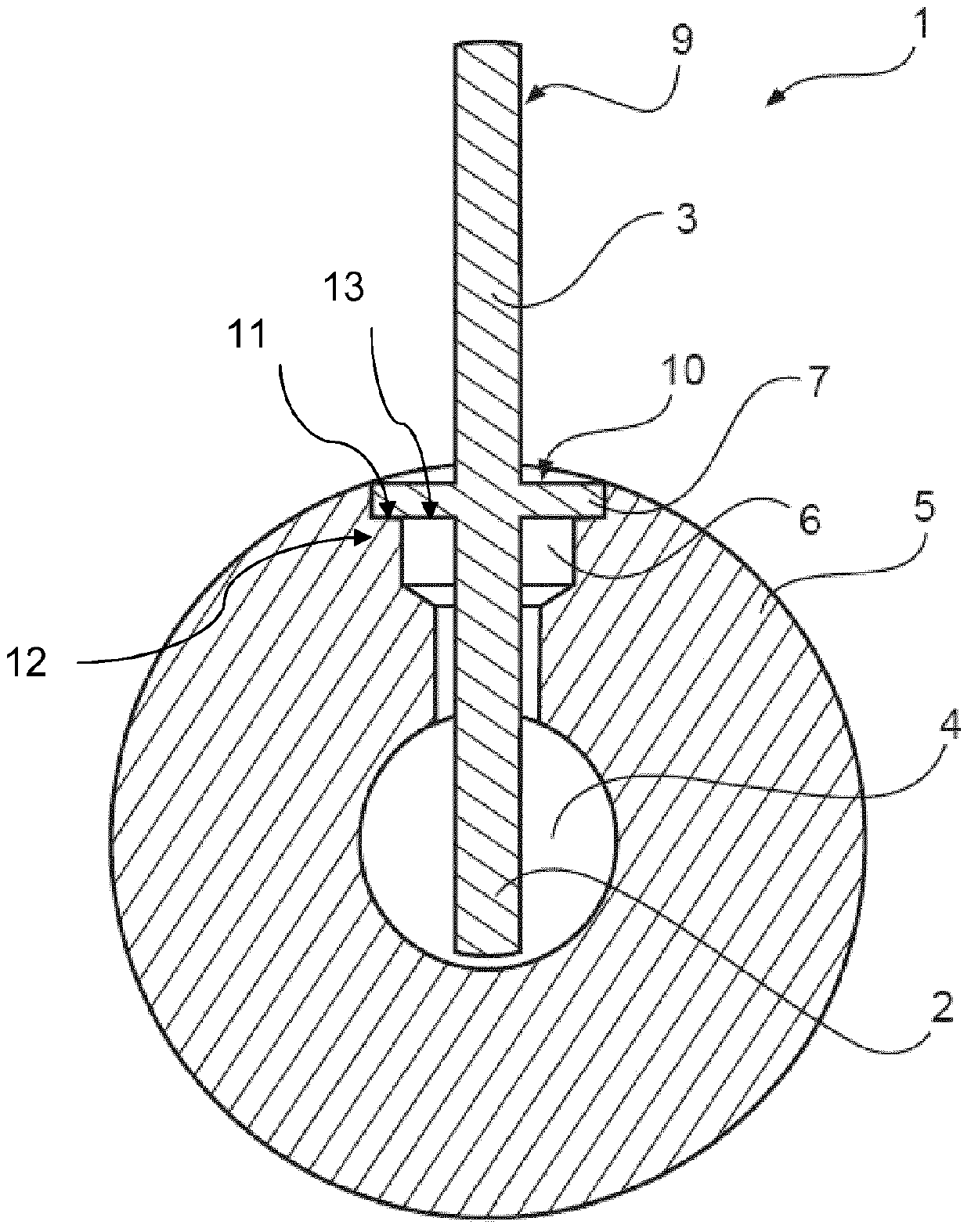

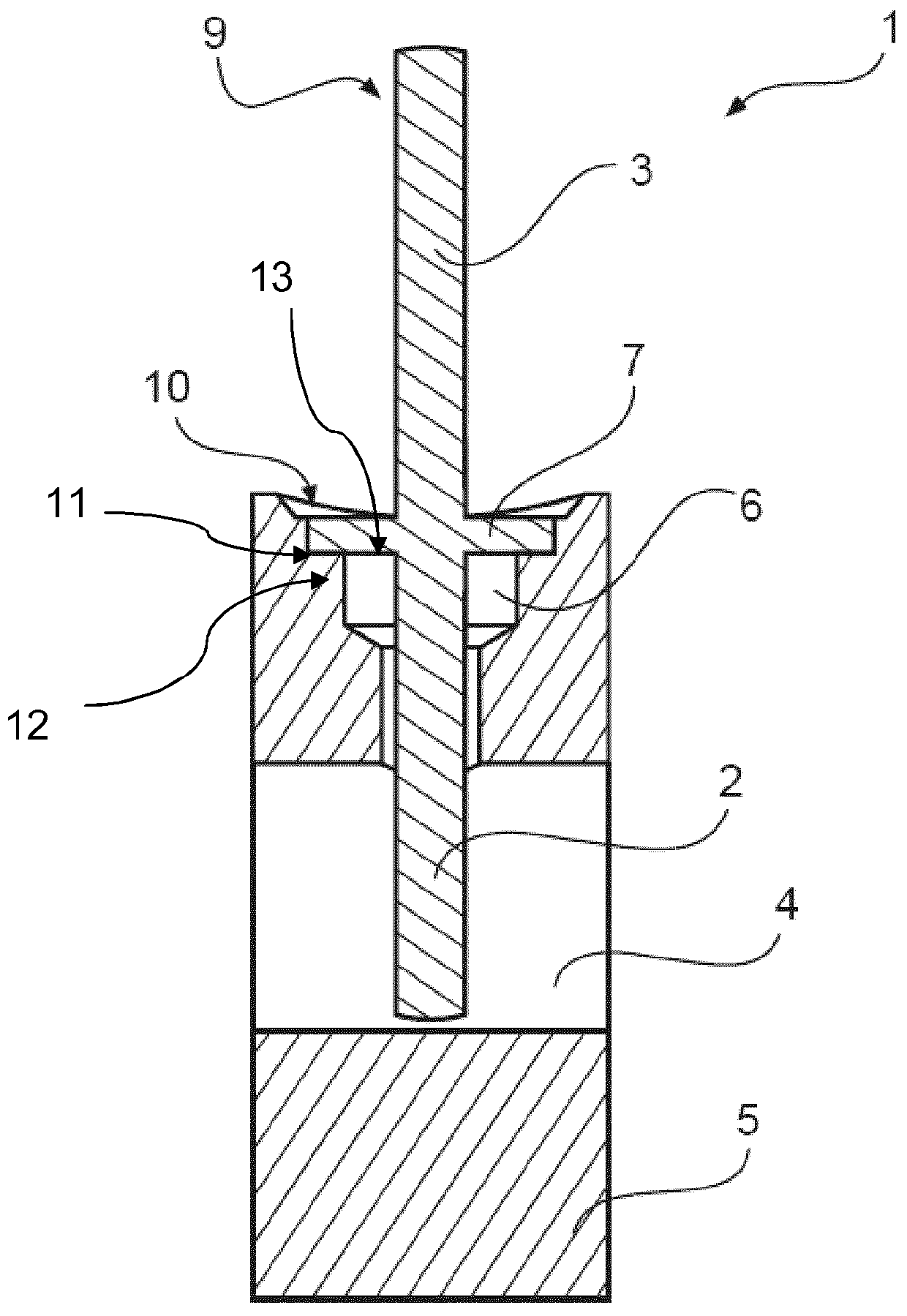

[0060] figure 2 and image 3 A cross section of the flow sensor 1 is shown. right f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com