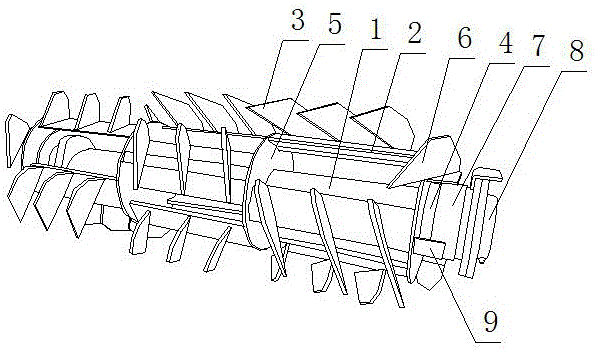

Rotary cultivator cutter shaft assembly

A technology of rotary tiller and rotary tiller, which is applied in the direction of tillage implements, agricultural machinery and implements, etc. It can solve the problems affecting the effect and quality of rotary tillage, the resistance of blades to the soil, and the different depths of rotary tillage, etc., to achieve improved Rotary tillage effect, low resistance to entry into the soil, and the effect of reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The cutter shaft assembly of the rotary tiller includes a cutter shaft 1, a tiller seat 2, a rotary tiller 3 and a weed protection ring 4. The cutter shaft 1 is fixed with assembly discs 5 at intervals, and the circumferences of two adjacent assembly discs 5 are A plurality of cultivating knife seats 2 are welded between. The cultivating knife seat 2 is in the shape of a strip, and its cross section is "∩"; the cultivating knife seat 2 is arranged in a dislocation shape between the assembly disks 5 . A plurality of rotary cultivating knives 3 are welded on the cultivating knife seat 2, and the rotary cultivating knives 3 on the adjacent cultivating knife seats 2 between each assembly disc 5 are installed in a dislocation shape, and the rotary cultivating knives on the adjacent cultivating knife seats 2 3 are opposite to each other. Thereby reducing the resistance of the rotary tiller 3 into the soil, so that the soil is not compacted after rotary tillage; effectively i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com