Threshing harvester

A technology for harvesters and harvesting devices, which is applied to harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of reduced production efficiency, increased labor force, and low production efficiency, and achieve the goal of improving work efficiency and reducing labor force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

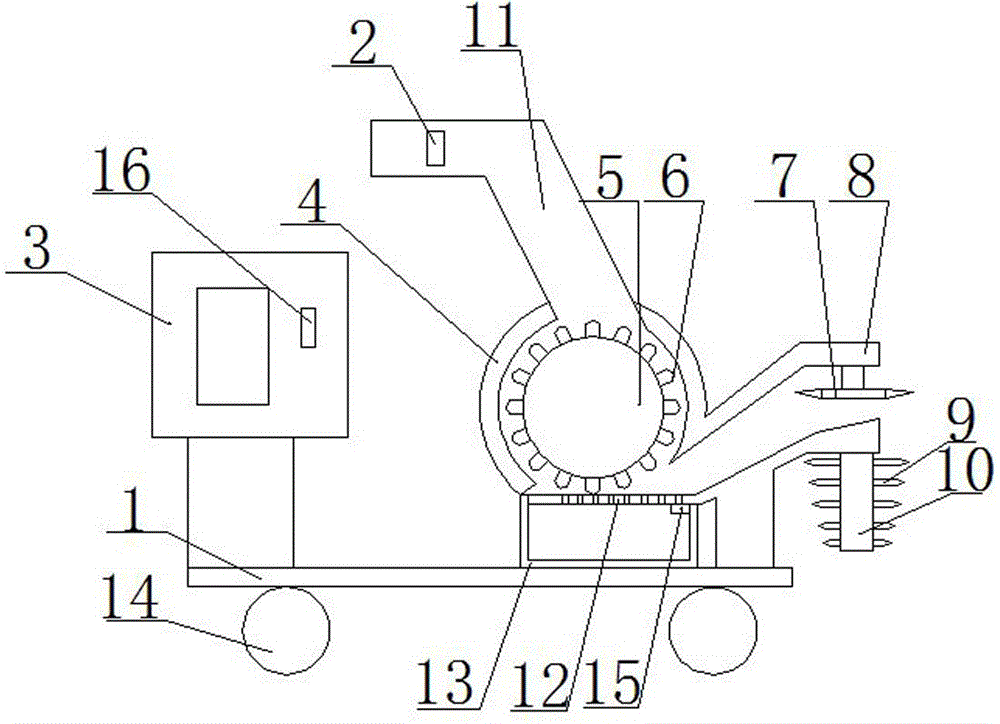

[0012] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

[0013] figure 1 Shown is a threshing harvester provided by the present invention, including: vehicle frame 1, suction fan 2, driver's cab 3, detachment housing 4, drum 5, threshing bump 6, harvesting cutter 7, harvesting port 8, cutter 9. Rotating cylinder 10, discharge channel 11, through hole 12, wheat storage box 13, sensor 15, controller 16, alarm and traveling wheel 14. Described vehicle frame 1 is provided with driver's cab 3, threshing device and reaping device, and its lower end is provided with traveling wheel 14; There is a rotating cylinder 10, and the rotating cylinder 10 is provided with multiple sets of cutters 9 from top to bottom, and the length of the cutters 9 decreases successively; The upper part is evenly covered with threshing bumps 6; the lower end of the threshing shell 4 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com