Straw picking-up fine powder throwing returning machine

A fine powder and frame technology, applied in loaders, harvesters, crop processors, etc., can solve problems such as difficult natural decay, easy to produce a large number of pests in planting, and unsatisfactory crushing effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

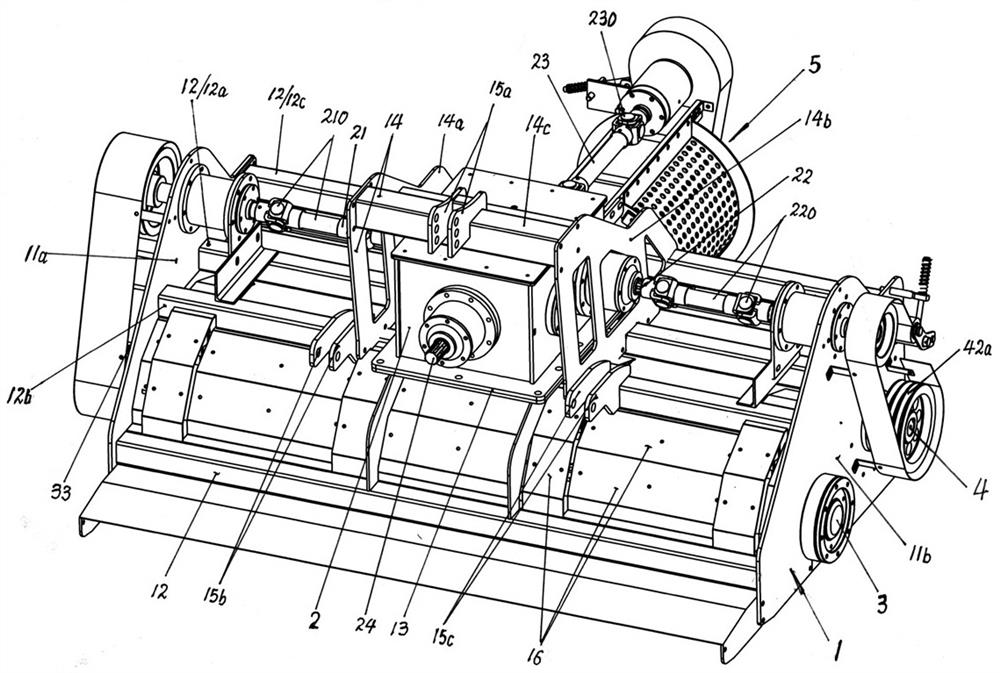

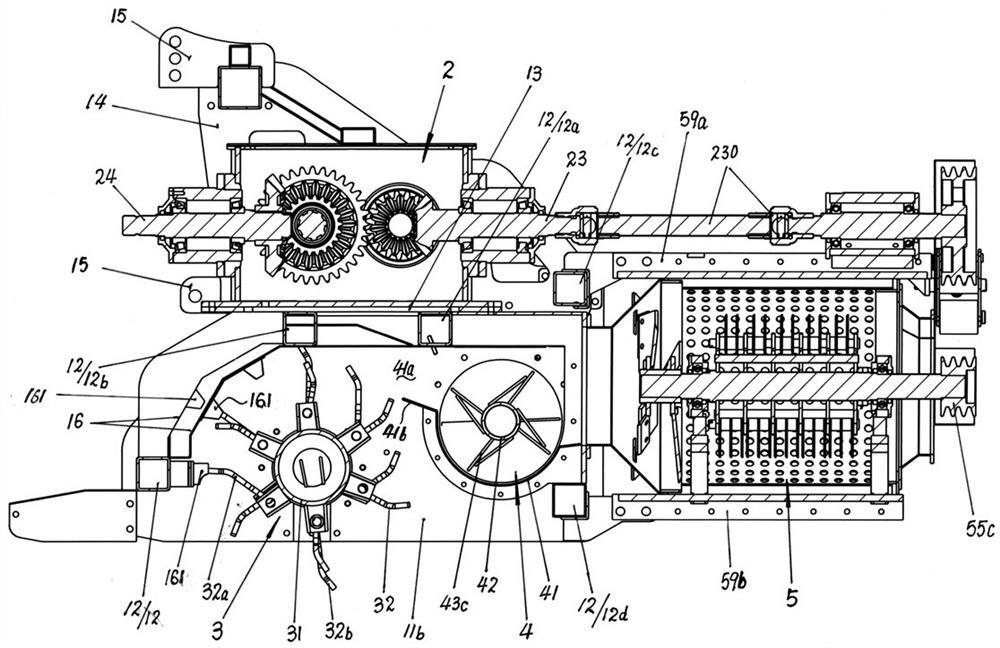

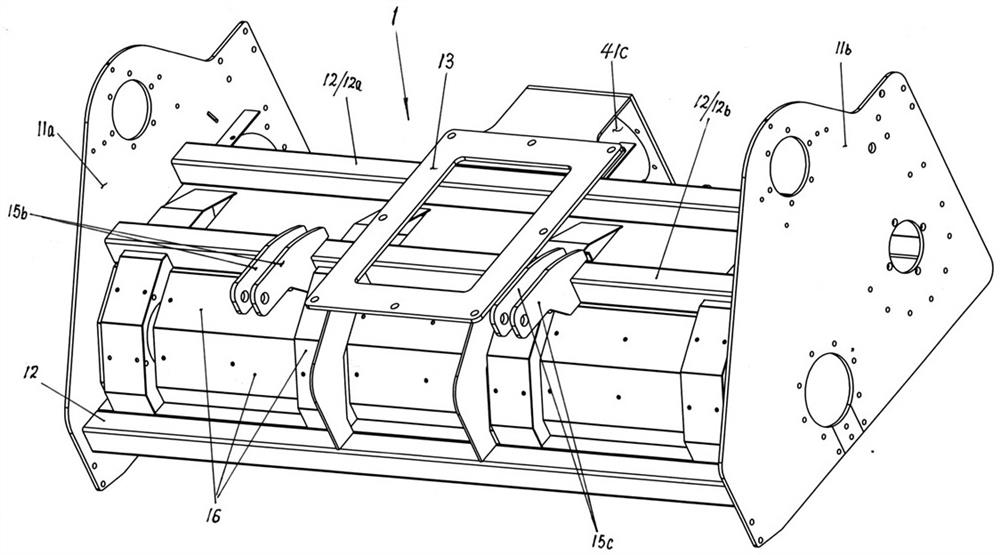

[0021] The machine for picking up fine powder of straw and throwing and returning to the field of the present invention is composed of a frame 1, a gearbox 2, a rotary picking and crushing knife roller device 3, a straw auger pushing roller device 4, and a cylindrical sieve type guillotine cutting and crushing device 5.

[0022] The frame 1 includes a left frame plate 11a, a right frame plate 11b, a plurality of beam frame rods 12, a gearbox installation base 13, a lifting lug frame 14, an upper lug 15a, a left lug 15b, a right lug 15c, and a cover 16; The left frame plate 11a and the right frame plate 11b are fixedly connected to the left and right ends of the beam frame rod 12, the gearbox mounting base 13 is fixedly installed on the middle part of the upper beam frame rods 12a, 12b, and the gearbox 2 is fixedly mounted on the gearbox mounting base 13 on;

[0023] Hanger frame 14 is made of left vertical plate 14a, right vertical plate 14b, beam bar 14c, and left vertical pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com