Cotton swab baking box

A technology of baking oven and cotton swab, applied in the field of oven machine, can solve the problems of insecurity, fire, unsuitable for baking cotton swabs, etc., and achieve the effect of stable dry and humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

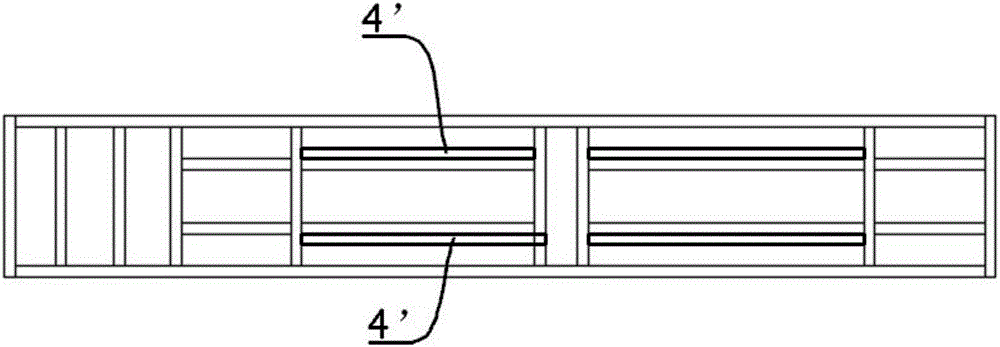

[0016] In order to enable the examiner to further understand the structure, features and other purposes of the present invention, the attached preferred embodiments are now attached in detail as follows with attached drawings, and the embodiments illustrated in the drawings are only used to illustrate the technical solution of the present invention , not to limit the present invention.

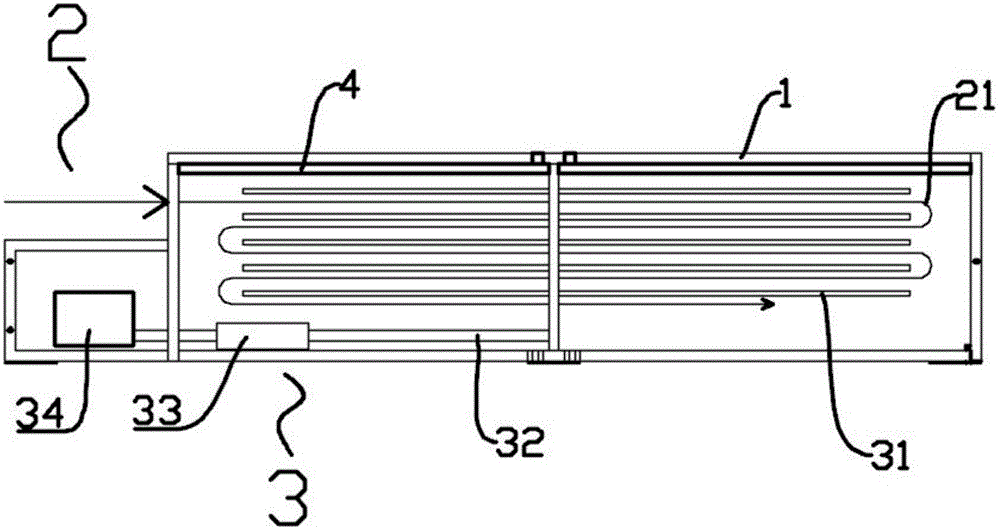

[0017] Such as figure 1 As shown, a cotton swab oven provided by the present invention includes a cabinet 1, which is characterized in that a heating system 3 and a cotton swab transmission system 2 are arranged in the cabinet 1;

[0018] Cotton swab transmission system 2, the cotton swab transmission system 2 is a chain transmission mechanism 21 that can carry cotton swabs for transportation, and the chain transmission mechanism 21 is distributed in an S shape in the vertical direction in the inner space of the oven;

[0019] The heating system 3 includes a drying pipeline 31 located between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com