Constant voltage overvoltage protector

A technology of overvoltage and protectors, applied in overvoltage protection resistors, varistors, etc., can solve the problems that arresters are prone to explosion, achieve the effect of eliminating explosion phenomena, solving explosion problems, and enhancing safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

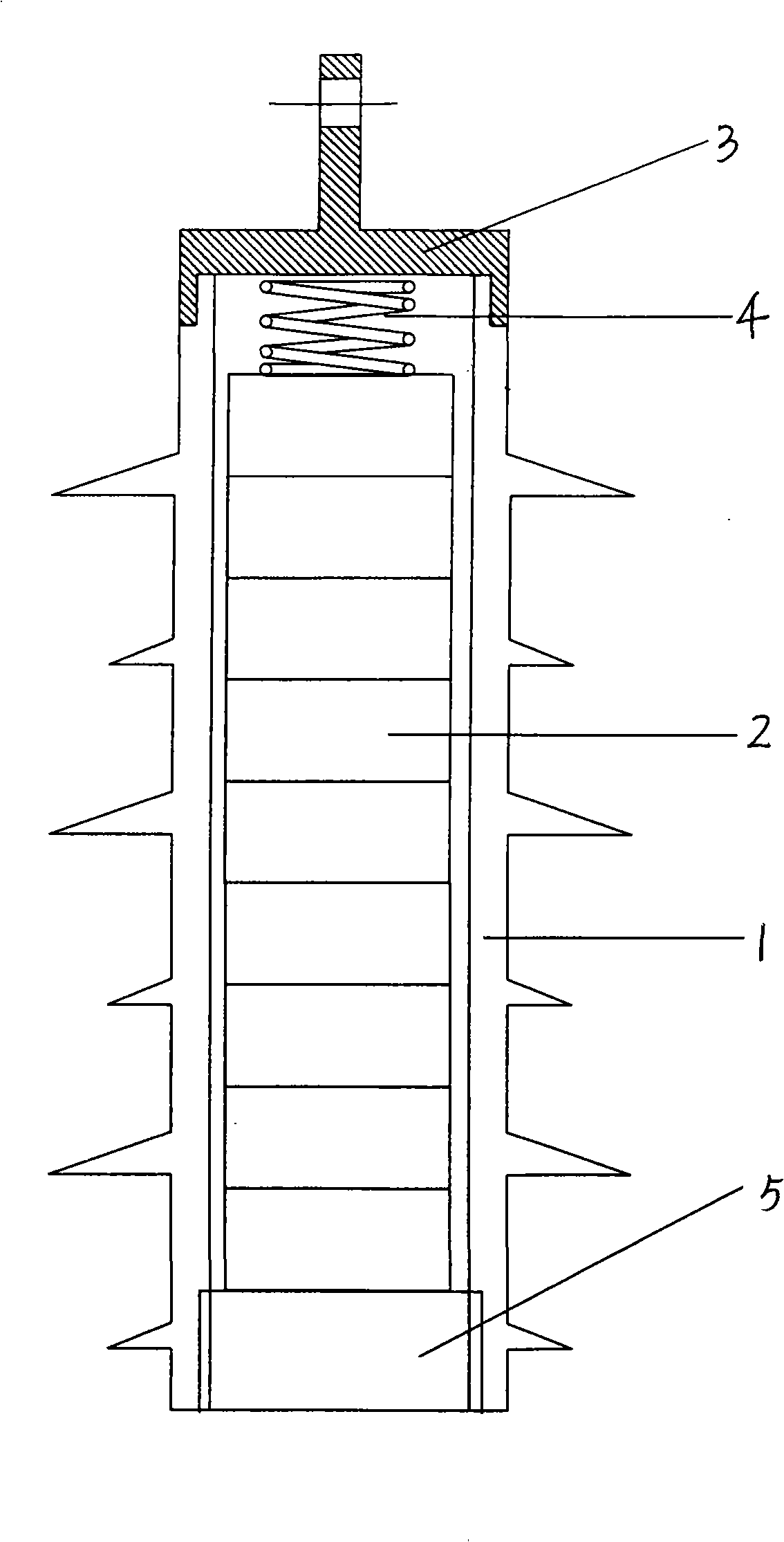

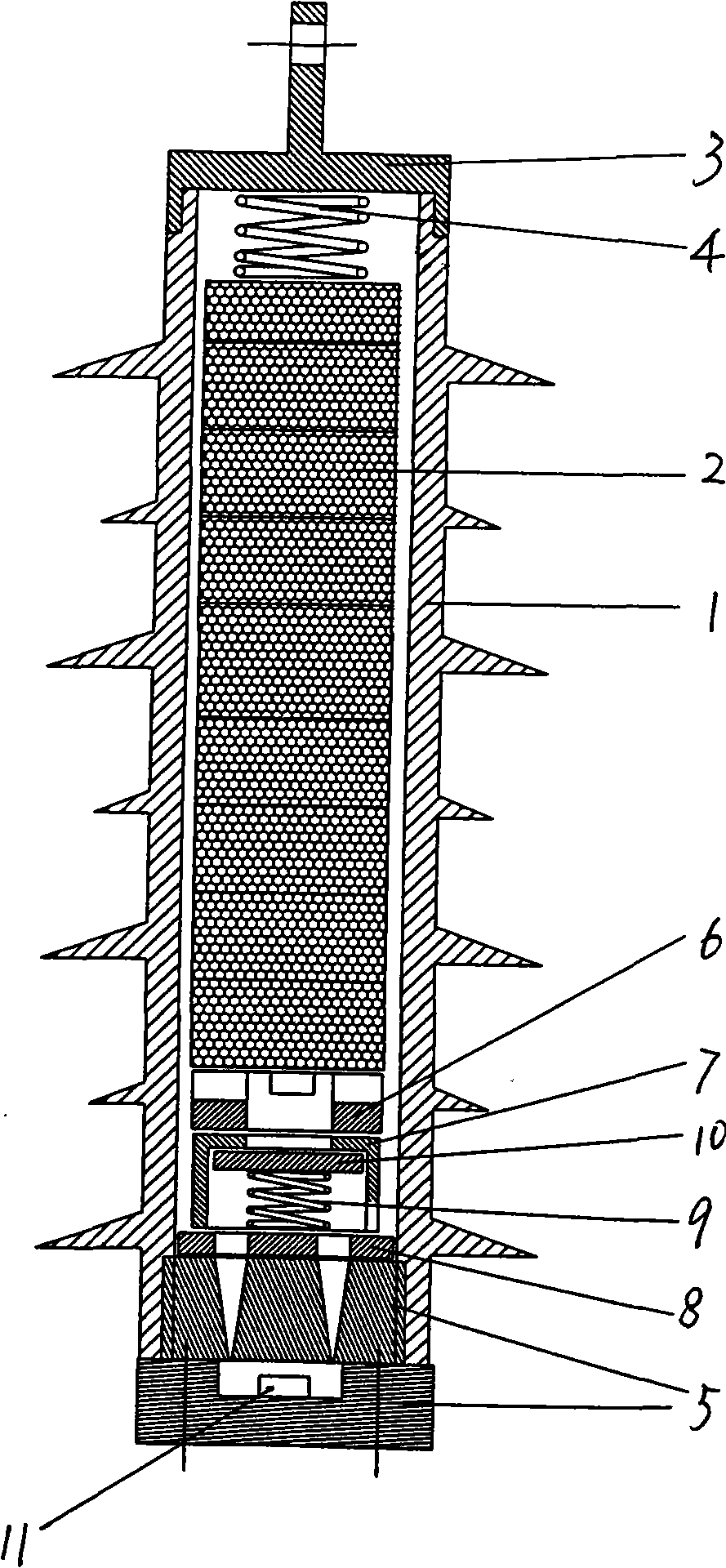

[0018] The constant voltage overvoltage protector includes an insulating sleeve 1, a zinc oxide valve plate 2 is installed inside the insulating sleeve 1, a metal cap 3 is installed on the upper end of the insulating sleeve 1, and a metal cap 3 is installed between the zinc oxide valve plate 2 and the metal cap 3. There is an upper spring 4, a metal blocking seat 5 is installed at the bottom of the insulating sleeve 1, a gap ring block 6, an epoxy material cover tube 7, and a small hole in the middle are stacked in sequence between the zinc oxide valve plate 2 and the metal blocking seat 5 Positive pressure sealing disc 8, the gap ring block 6 and the middle part of the cover tube 7 have openings to communicate with each other, there is a gap on the side wall of the gap ring block 6 to communicate with the opening and the inner cavity of the insulating sleeve 1, and the inside of the cover tube 7 There is a lower spring 9, the lower end of the lower spring 9 presses on the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com