Glass double face synchronous cutter

A cutter, double-sided technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of inaccurate correspondence, glass cannot be completely cracked, glass crushing, etc., and achieve accurate cutting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

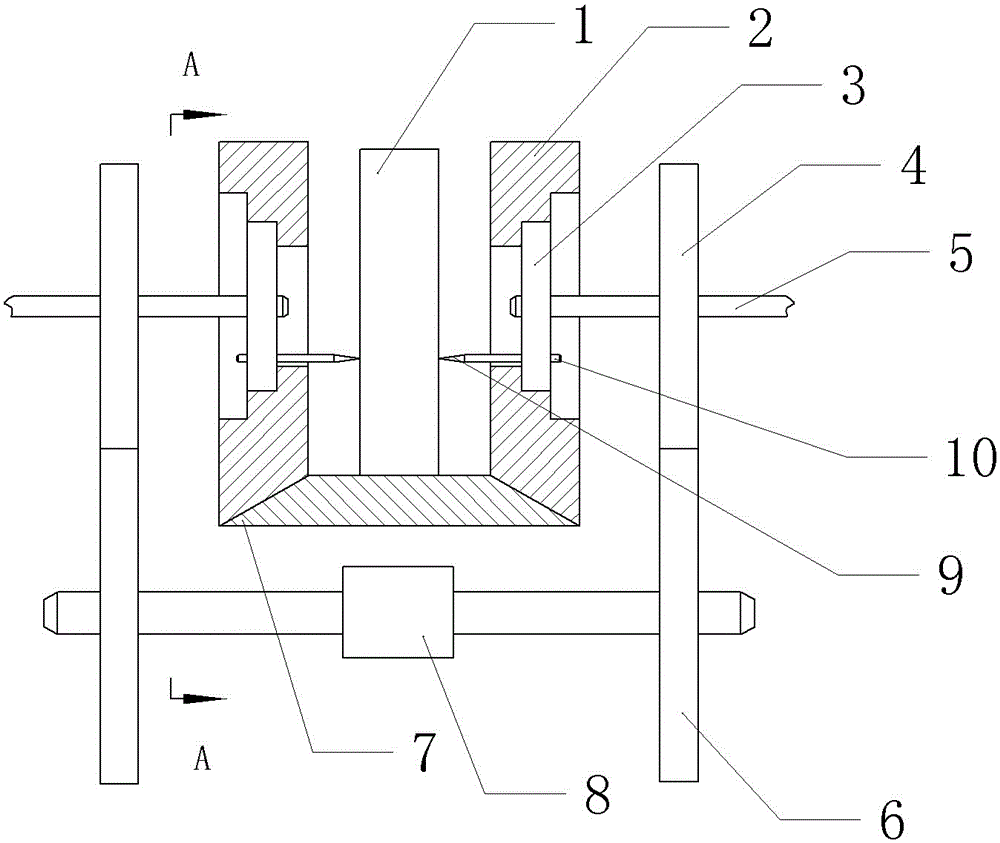

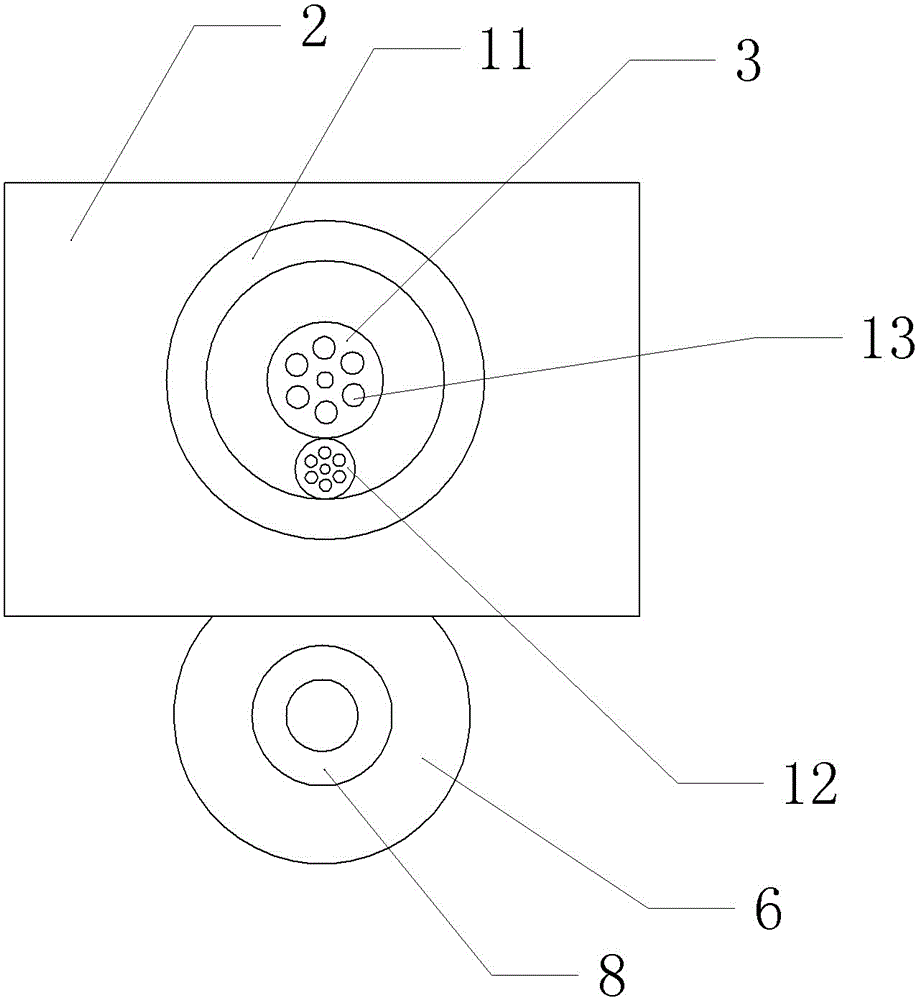

[0017] Among them: glass 1, side plate 2, sun gear 3, driven gear 4, main shaft 5, driving gear 6, bottom plate 7, motor 8, blade 9, split shaft 10, first through hole 11, planetary gear 12, second Through hole 13.

[0018] Such as figure 1 , figure 2 As shown, the glass double-sided synchronous circular cutter of the present invention includes a "U"-shaped plate and two main shafts 5, the "U"-shaped plate includes two side plates 2 and a bottom plate 7, and the cross-section of the bottom plate 7 is inverted " V-shaped, two side plates 2 are symmetrically arranged on both sides of the bottom plate 7, and the “U”-shaped plate is placed vertically. Both side plates 2 of the “U”-shaped plate are provided with a first through hole 11. The first through-hole The hole 11 is a stepped hole, and the inner diameter of the stepped hole increases sequentially from the inside to the outside; the first through hole 11 is provided with a ring gear, and the ring gear is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com