A spiral capsule dryer with automatic feeding device

An automatic feeding and spiral technology, which is applied in the direction of drying machine, drying solid materials, drying, etc., can solve the problems of capsule outer surface hardening, uneven heating, high labor intensity, etc., so as to improve drying efficiency and reduce production Labor intensity, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

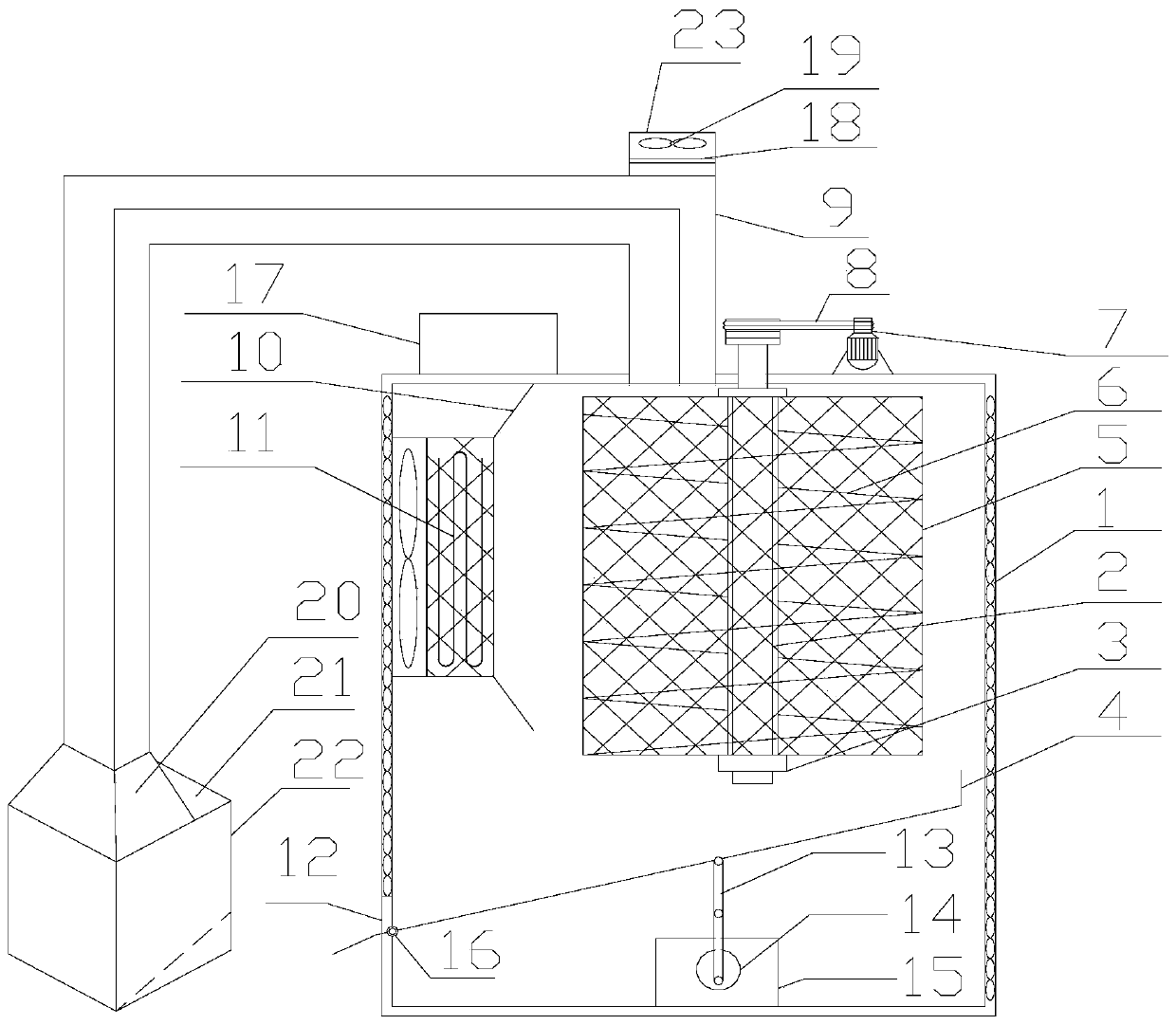

[0012] refer to figure 1 , a spiral capsule dryer with an automatic feeding device in the present invention, including a box body 1, a rotating shaft 2, a drying cylinder installation snap ring 3, a blanking plate 4, a drying cylinder 5, a spiral guide plate 6, a rotating shaft motor 7, Conveyor belt 8, feed pipe 9, air duct expansion board 10, electric heating fan 11, discharge port 12, connecting rod 13, eccentric wheel 14, motor 15, hinge 16, negative pressure fan control device 17, filter screen 18, strong Negative pressure fan 19, feed port 20, feed port 21, material storage box 22 and negative pressure fan placement box 23, the box body 1 is provided with a discharge port 12, and the outside of the box body 1 is equipped with a rotating shaft motor 7 and a negative pressure fan control device 17, the inside of the box 1 is equipped with a rotating shaft 2, an electric heating fan 11 and a blanking plate 4, the drying cylinder 5 is installed on the rotating shaft 2 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com