Efficient hot-air type capsule drying device

A drying device and capsule technology, applied in the direction of drying gas arrangement, non-progressive dryer, capsule transportation, etc., can solve problems such as adhesion, capsule outer surface hardening, melting, etc., achieve uniform heating, improve drying efficiency, increase air The effect of velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

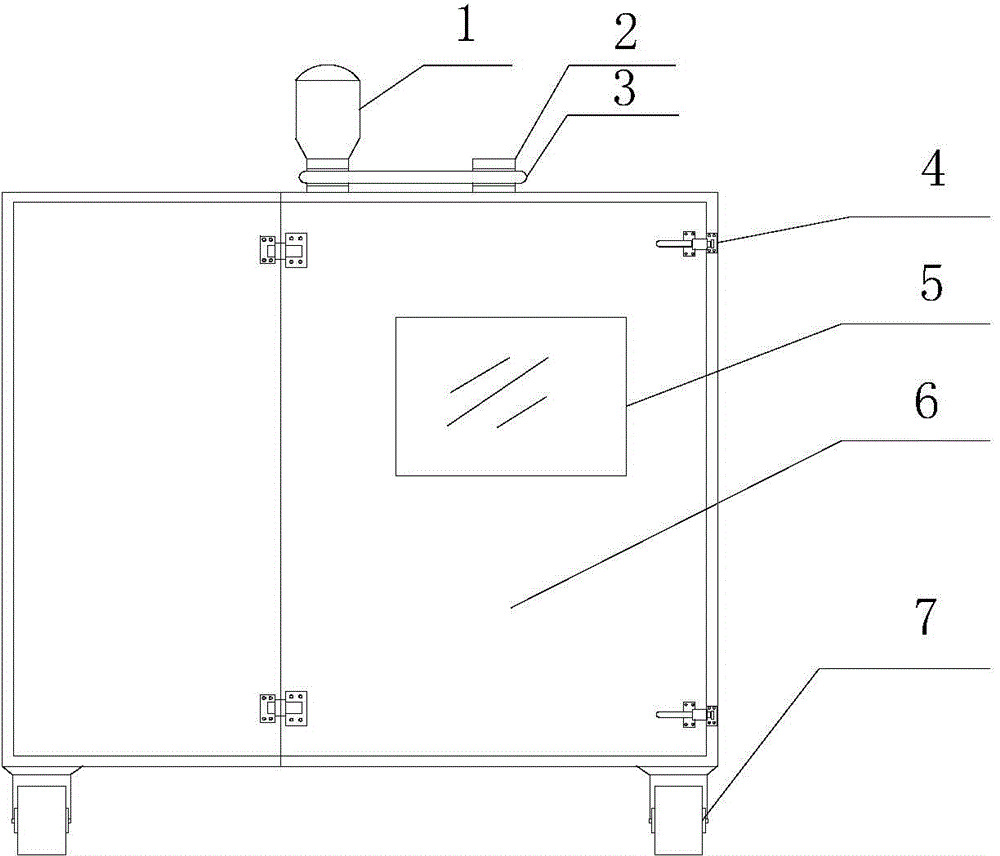

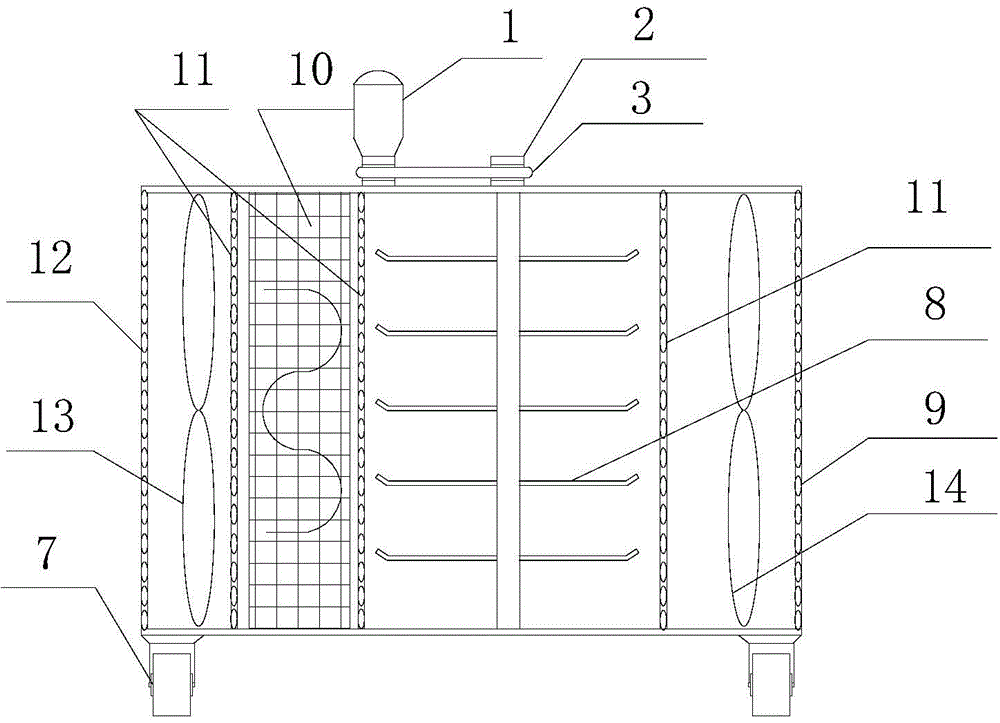

[0013] refer to figure 1 , figure 2 , a high-efficiency hot air capsule drying device of the present invention, comprising a motor 1, a rotating shaft 2, a conveyor belt 3, a box door fixing device 4, a viewing window 5, a box door 6, universal wheels 7, a mesh capsule discharge rack 8, Moisture outlet 9, electric heating device 10, protective plate 11, air inlet 12, fan 13 and negative pressure fan 14, the motor 1 is fixed on the drying box, the rotating shaft 2 is fixed inside the drying box, the The motor 1 is connected to the rotating shaft 2 through the conveyor belt 3, and the box door 6 is fixed on the drying box by the box door fixing device 4. The box door 6 is provided with a visible window 5, and the lower bottom surface of the box door 6 is Universal wheels 7 are installed, the mesh capsule placement frame 8 is fixed on the rotating shaft 12, the air inlet 12 and the moisture outlet 9 are respectively opened on both sides of the drying box, the electric heating d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com