Multi-component three-dimensional digital core building method based on multi-source information fusion

A multi-source information fusion, three-dimensional digital technology, which is applied in the field of multi-component three-dimensional digital core construction with multi-source information fusion, can solve the problems that cannot describe reservoir cores and affect the application of three-dimensional digital cores. The accuracy of numerical simulation of petrophysical properties, Problems such as the spatial distribution of micro-pores cannot be

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical means adopted by the present invention to achieve the intended invention purpose are further described below in conjunction with the drawings and preferred embodiments of the present invention.

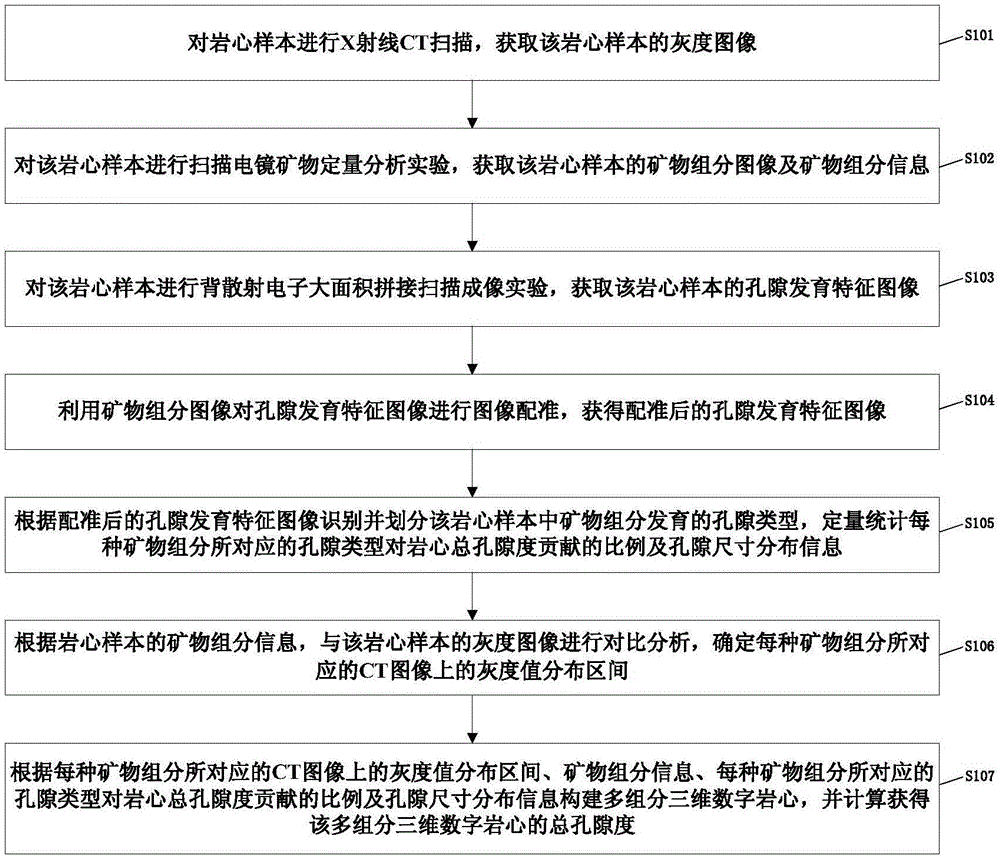

[0018] figure 1 It is a flowchart of a multi-component three-dimensional digital core construction method according to an embodiment of the present invention. Such as figure 1 As shown, the method includes:

[0019] Step S101, performing an X-ray CT scan on the core sample to obtain a grayscale image of the core sample;

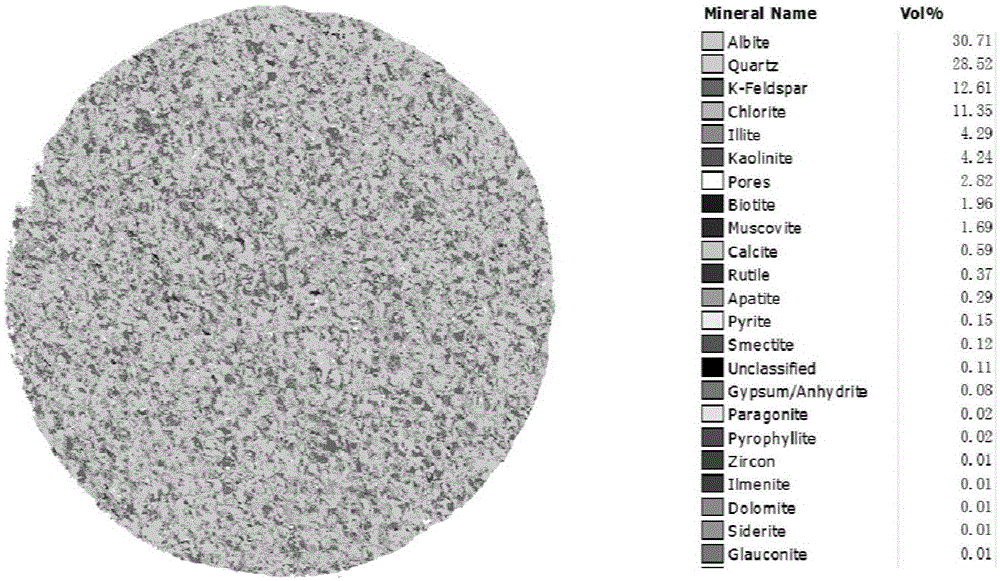

[0020] Step S102, performing a scanning electron microscope mineral quantitative analysis (Qemscan) experiment on the core sample to obtain the mineral composition image and mineral composition information of the core sample;

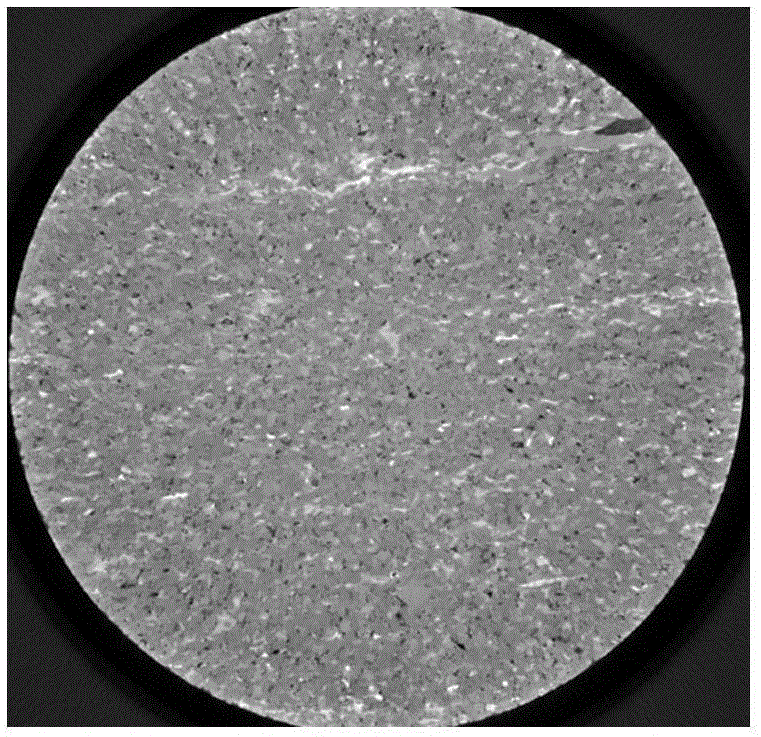

[0021] Step S103, performing a backscattered electron large-area mosaic scanning imaging (Maps) experiment on the core sample to obtain a characteristic image of the pore development of the core sample;

[0022] Step S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com