Multidisciplinary and reliable modeling method of hydraulic servo mechanism based on failure mechanism

A failure mechanism, hydraulic servo technology, used in electrical digital data processing, special data processing applications, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

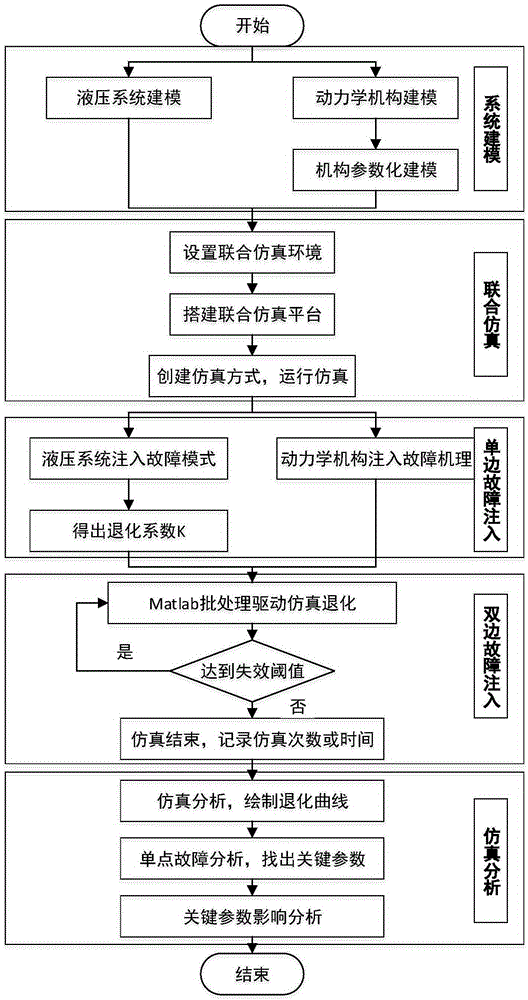

[0079] The present invention is a multidisciplinary reliability modeling method of hydraulic servo mechanism based on failure mechanism, such as figure 1 Shown; The method is carried out according to the following five stages successively; The present invention adopts the connecting rod mechanism controlled by hydraulic pressure as a case, and the specific implementation is described in detail as follows:

[0080] Phase 1: System Modeling

[0081] System modeling is divided into the following three steps:

[0082] Step ⑴ Dynamic Mechanism Modeling:

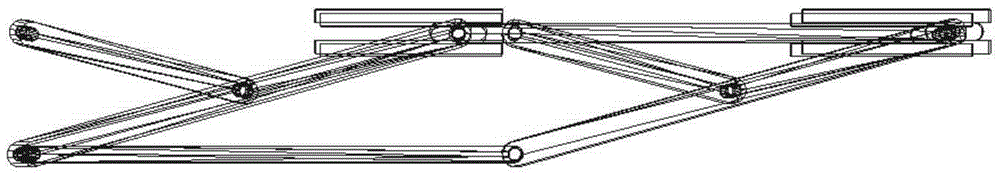

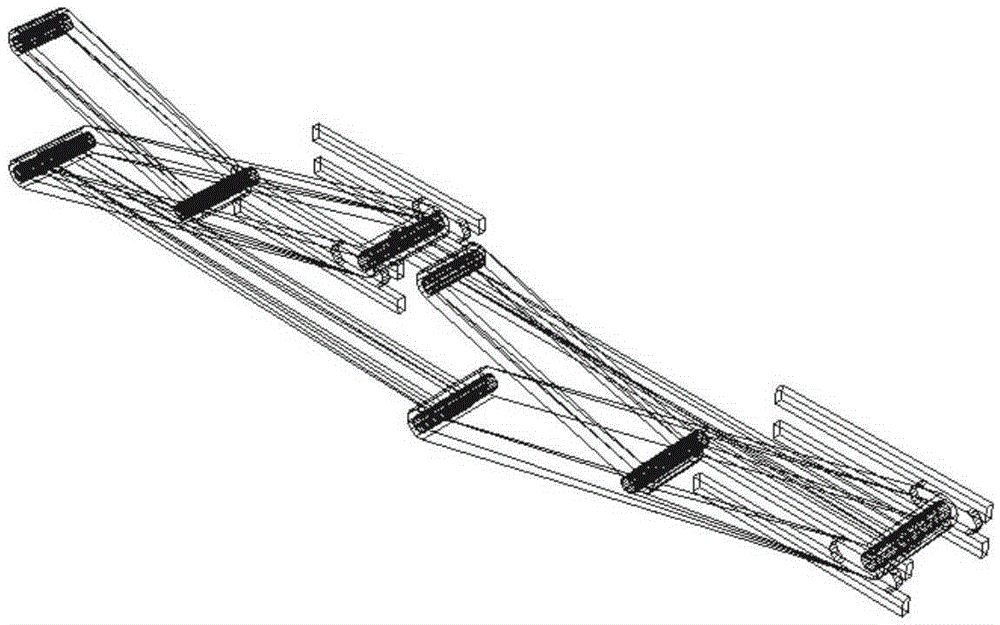

[0083] In ADAMS, the 3D solid model of the connecting rod mechanism with the nominal size of the mechanism is first established. The solid model is shown in Figure 2; after that, constraints and kinematic pairs are added to the 3D model. The kinematic pair numbers in the ADAMS model are as follows: image 3 shown. Among them, the housing of the connecting rod mechanism is fixedly connected to the ground; the front and rear slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com