Temperature controller pedestal and manufacturing technique

A thermostat and bottom plate technology, applied in electrical components, electrical switches, circuits, etc., can solve problems such as poor market, riveting pressure deformation and leakage, and achieve the effect of eliminating the risk of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

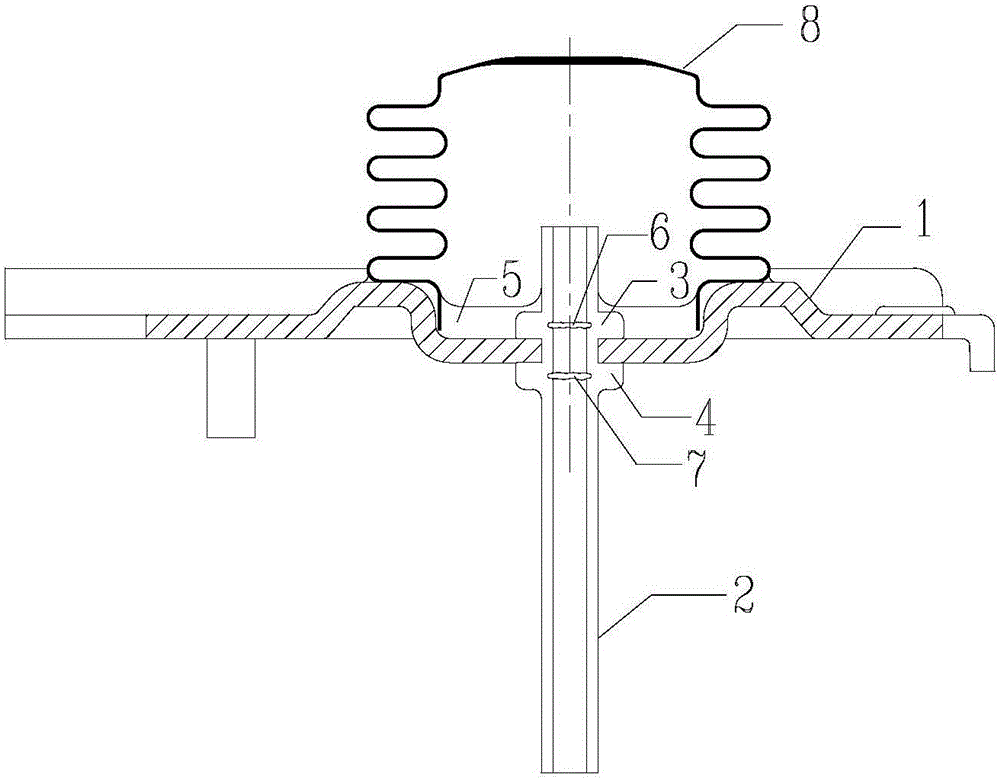

[0019] Such as figure 1 As shown, a thermostat base in the prior art includes a base plate 1 and a capillary tube 2, the upper surface of the base plate 1 is concave, the lower surface of the base plate 1 is convex, and a bellows 8 is soldered on the concave surface of the base plate, and the capillary tube 2 passes through Pass through the center of the bottom plate 1; the central perforation of the bottom plate 1 is used to install the capillary 2, the capillary 2 has two steps, one upper step 3, one lower step 4, the upper step 3 is against the concave surface of the bottom plate, the lower step 4 is against the convex surface of the bottom plate, the upper step Set a layer of solder 5 at step 3, from figure 1 In , it can be seen that there are two deformation grooves, namely the deformation groove 6 on the inner wall of the upper step and the deformation groove 7 on the inner wall of the lower step, both of which are riveted capillaries, and the inner wall performance afte...

Embodiment 2

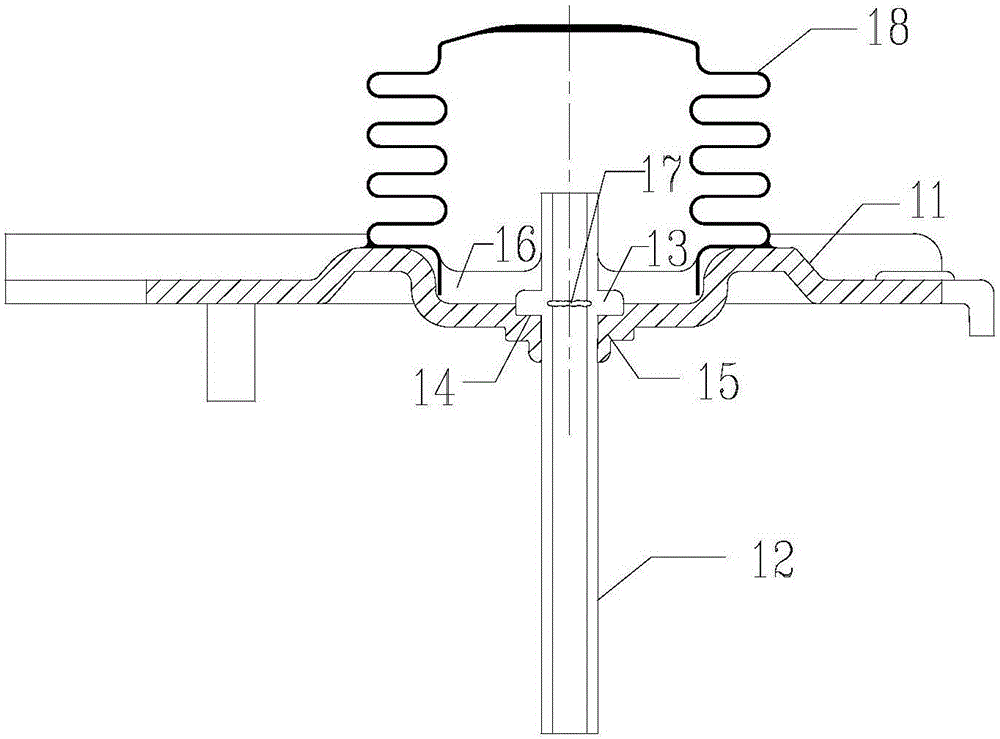

[0021] Such as figure 2 As shown, the present invention provides a thermostat base, including a base plate 11 and a capillary tube 12. The upper surface of the base plate 11 is concave, the lower surface of the base plate 11 is convex, and a bellows 18 is soldered on the concave surface of the base plate, and the capillary tube 12 passes through the base plate. Center; the central perforation position of the bottom plate 11 is used to install the capillary 12, a circular concave platform 14 is set in the center of the concave surface of the bottom plate 11, and an edge clamping structure 15 is set in the center of the convex surface of the bottom plate 11, and the edge clamping structure 15 is superimposed by two convex platforms structure, used to clamp the capillary 12 passing through the bottom plate 11, the capillary 12 is provided with a step 13, the step 13 corresponds to the circular concave platform 14, and is installed in the circular concave platform 14, and the conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com