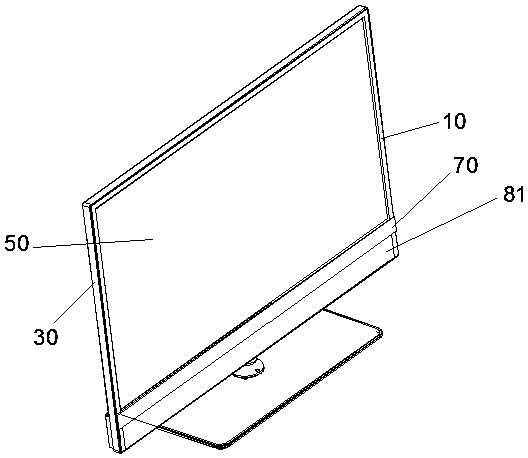

Television metal frame body and television thereof

A metal frame and TV technology, which is applied in the TV field, can solve the problems of difficult quality assurance, retention of hardware LCD screen shell, high cost, etc., and achieve the effects of reducing production costs, stylish and beautiful appearance, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the objectives, technical solutions and advantages of the present invention clearer and clearer, the present invention will be further described in detail below with reference to the drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

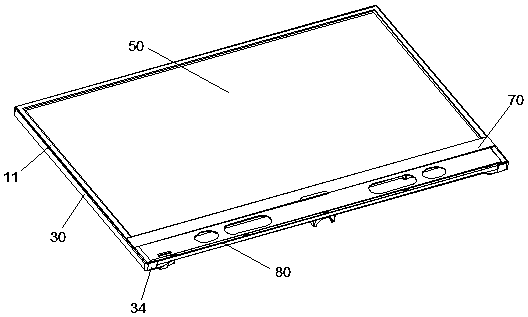

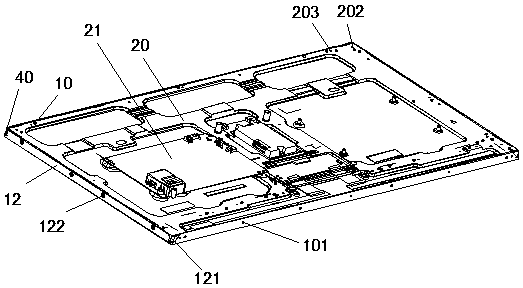

[0042] Please refer to Figure 4 , Figure 5 As shown, Figure 4 Is a schematic cross-sectional view of a preferred embodiment of a television of the present invention, Figure 5 Yes Figure 4 A partial enlarged schematic diagram at A. Among them, a metal frame of a television includes a liquid crystal screen housing 10 and a liquid crystal screen back plate 20. The liquid crystal screen housing 10 and the liquid crystal screen back plate 20 form an accommodating space for placing liquid crystal modules. The LCD housing 10 includes a front baffle 11 and a side baffle 12 extending along the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com