A small particle magnet automatic feeding device

A technology of automatic feeding and small particles, which is applied in metal processing and other directions, can solve problems such as processing interruption, jamming, and feeding failure, and achieve the effect of mass feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further explained below in conjunction with the drawings:

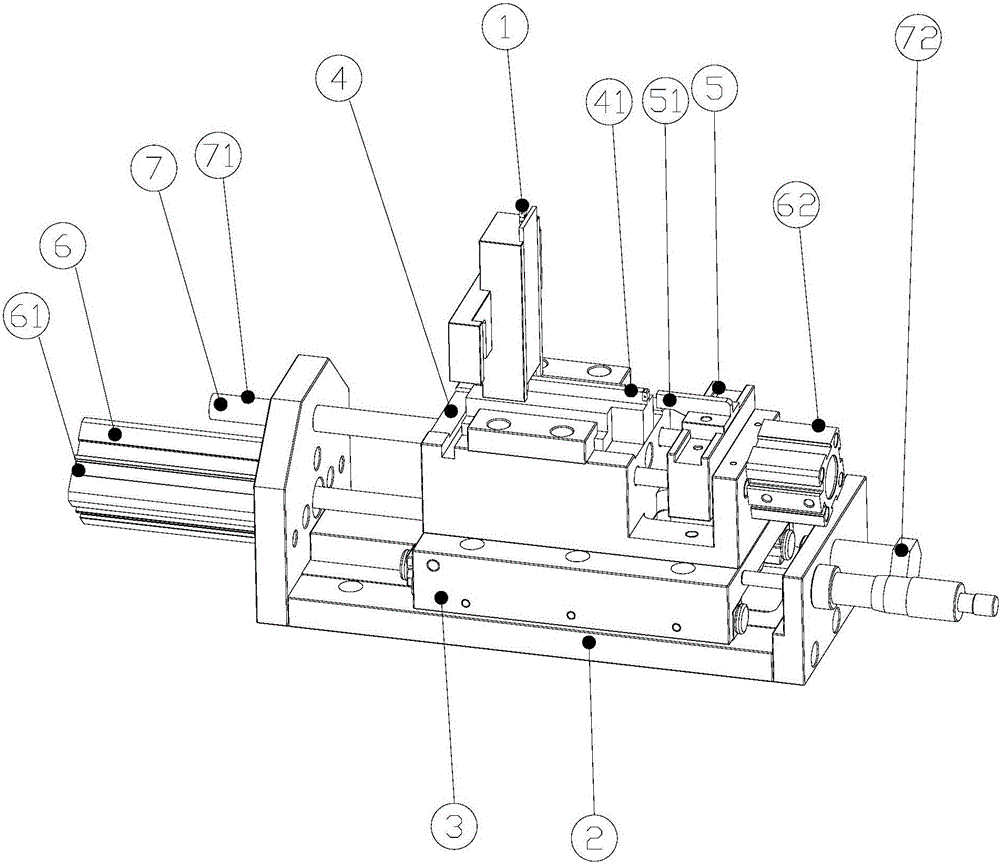

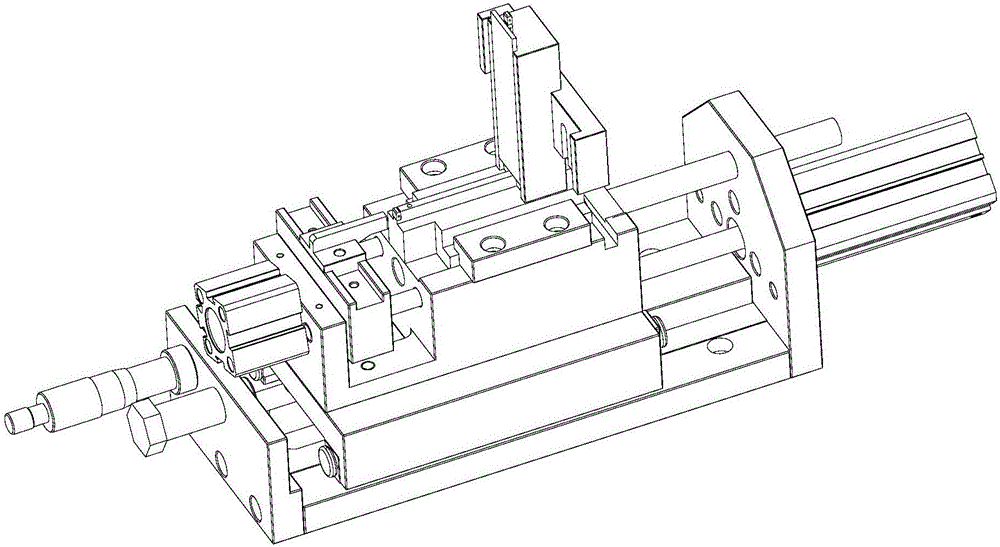

[0021] Such as figure 1 As shown, a small particle magnet automatic feeding device of the present invention includes a blanking device 1, a base 2, a fixing device 4, a mold base 41, a head 51, a driving device 6 and a limiting device 7; the first sliding device 3 is placed On the upper part of the base 2, the second sliding device 5 is placed inside the fixing device 4; the driving device 6 includes a first cylinder 61 and a second cylinder 62; the piston rod of the first cylinder 61 is connected to one end of the first sliding device 3, and the second The piston rod of the cylinder 62 is connected to one end of the second sliding device 5. The first cylinder 61 and the second cylinder 62 are respectively placed on both ends of the base 2; the limit device 7 includes a first limit adjustment rod 71 and a second limit Adjusting rod 72; the first limit adjustment rod 71 is set at one e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com