Power transmission line icing automatic monitoring device

A transmission line and monitoring device technology, which is applied in the field of power transmission, can solve the problems of automatic and effective monitoring of the icing situation of transmission lines, etc., and achieve the effects of easy promotion and use, real-time monitoring, and reduction of labor intensity and safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

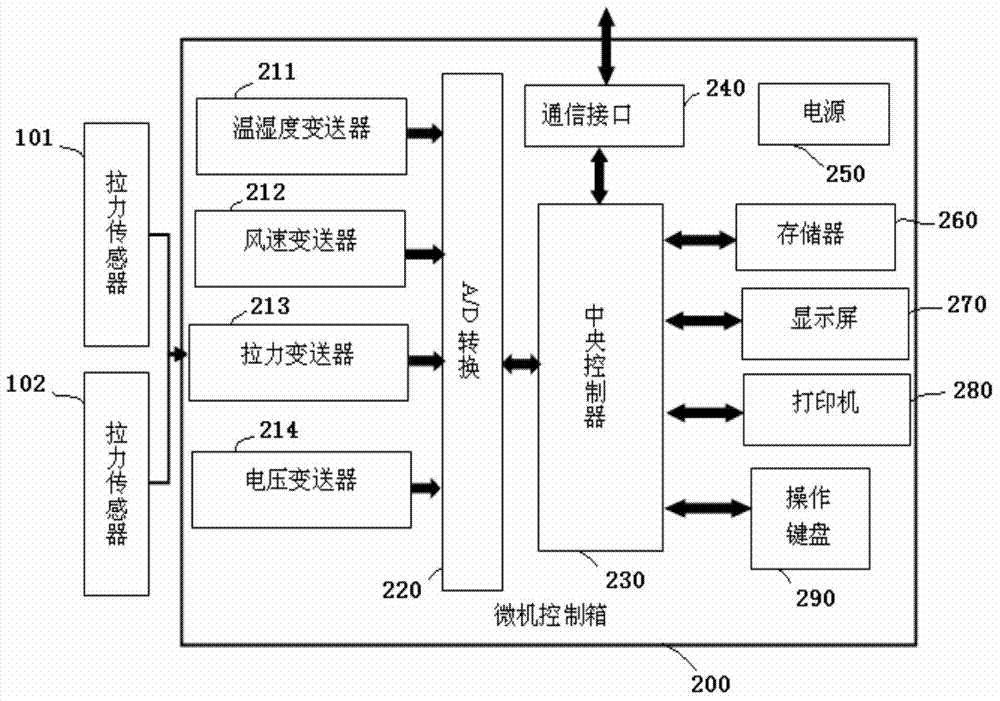

[0029] Such as figure 1 As shown, the transmission line icing automatic monitoring system of this embodiment includes: a sensor group (not all are shown in the figure) and a microcomputer control box 200 .

[0030] The sensor group includes: a tension sensor (tension sensor 101 and tension sensor 102) for measuring the icing weight of the simulated wire, a temperature and humidity sensor (not shown) for measuring the operating environment temperature and humidity of the transmission line, and A wind speed sensor (not shown in the figure) for measuring the wind speed of the transmission line operating environment.

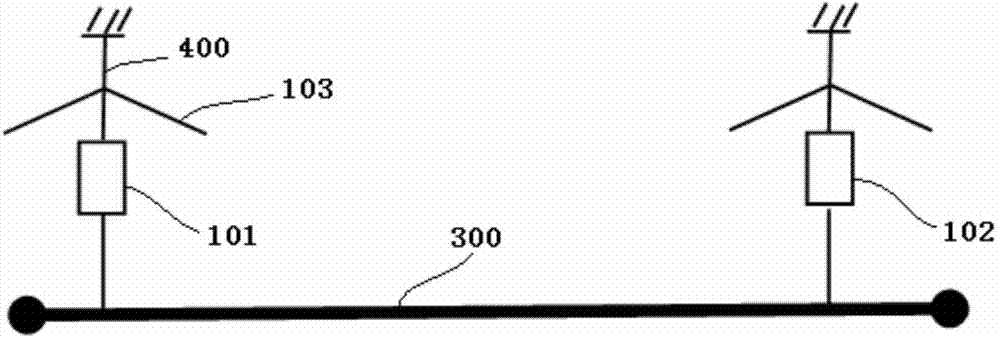

[0031] Such as figure 2 As shown, there are two tension sensors (i.e. tension s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com