Repair device, repair method, and component manufacturing method

A device and component technology, which is applied in the fields of repairing devices and repairing and device manufacturing, can solve problems such as current supply current capacity of difficult devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

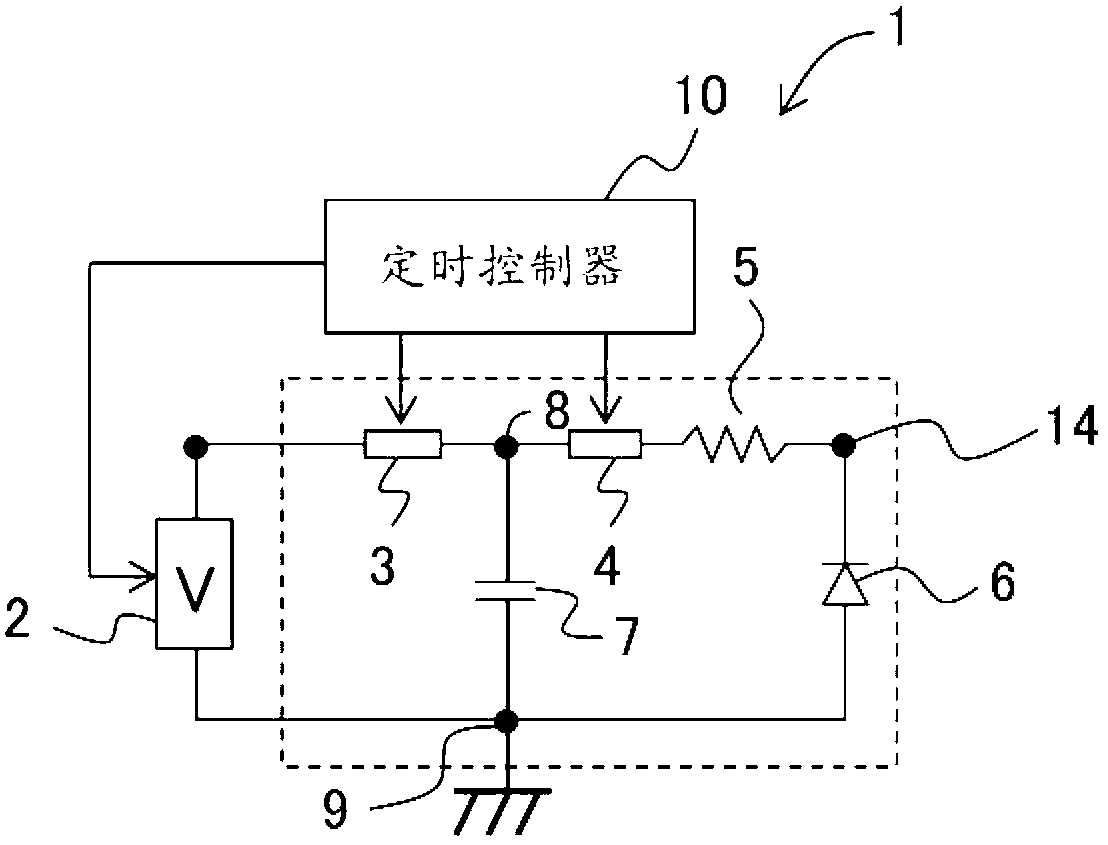

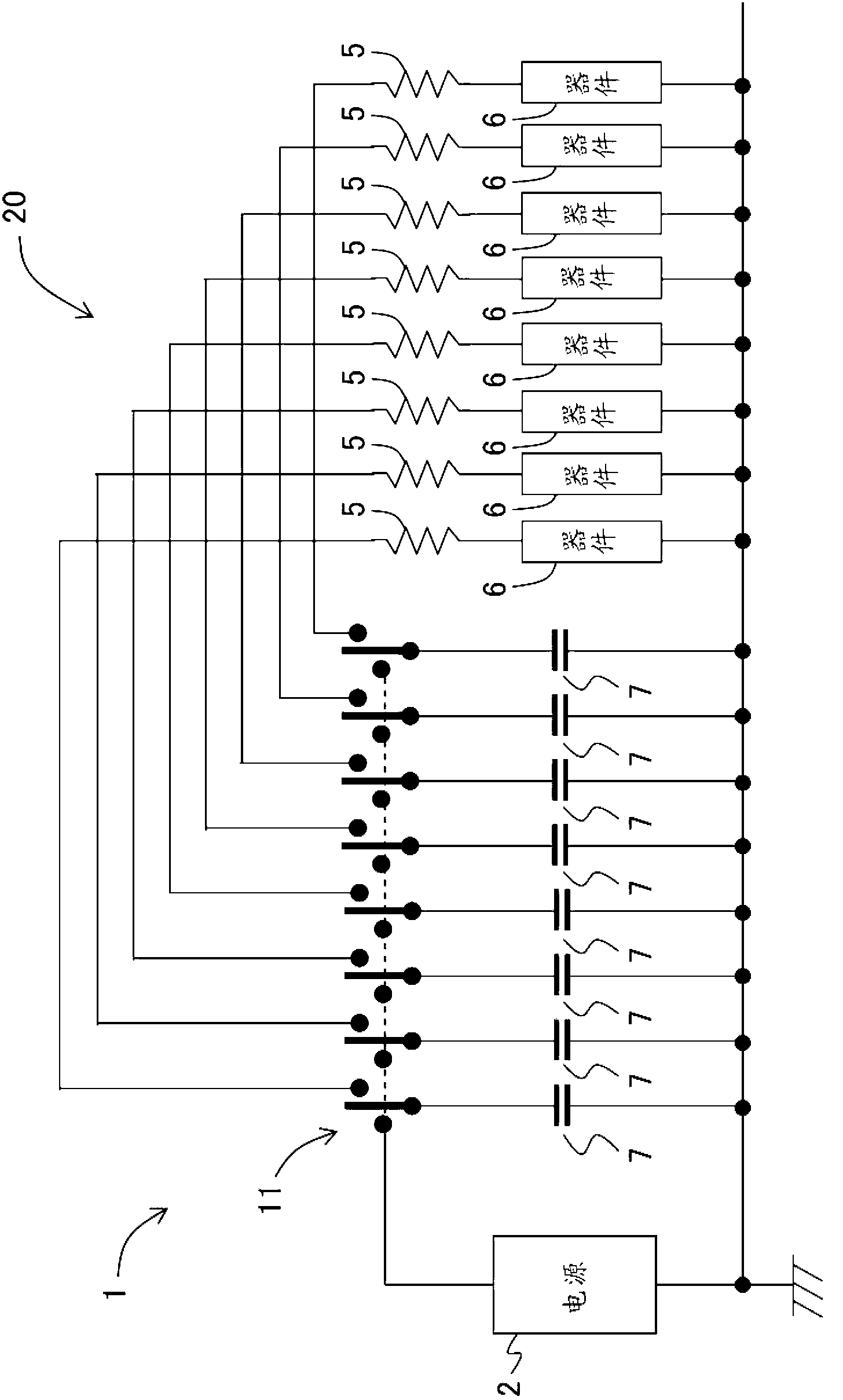

[0127] figure 1 It is a circuit block diagram schematically showing an example of the unit configuration of the repair device in Embodiment 1 of the present invention. In addition, in the repairing device, there is one unit structure example and a portion surrounded by a dotted line, but there are multiple unit structure examples, in particular, three or more, or about ten to several hundred, or even other. above.

[0128] exist figure 1 Among them, in the repairing device 1 according to the first embodiment, one terminal of the high voltage power supply 2 whose output voltage can be freely varied is connected to one end of the application resistor 5 through the high withstand voltage relays 3 and 4 . The other end of the application resistor 5 is connected to one terminal of a device 6 to be inspected and processed. The other terminal of the inspection and processing object device 6 is connected to the other terminal of the high-voltage power supply 2 . The connection p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com